Agilawood essential oil extraction method

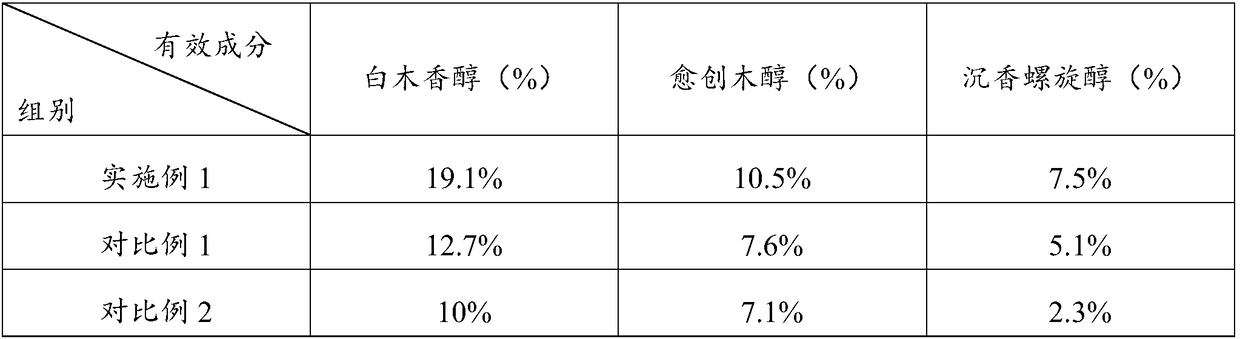

A kind of technology of agarwood essential oil and extraction method, which is applied in the direction of essential oil/fragrance, fat production, etc., can solve the problems of low active ingredient content and unsatisfactory effect of agarwood essential oil, etc., achieve high active ingredient content, convenient distillation method, and simple operation easy effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] A kind of extraction method of agarwood essential oil, the quality of used agarwood wood raw material is 1000g, comprises the following steps:

[0025] (1) Agarwood is carried out to freeze-drying process;

[0026] (2) pulverizing the agarwood processed in step (1) to obtain agarwood chips;

[0027] (3) Transfer the agarwood wood chips to the dry distillation reaction kettle, and add salt water therein so that the salt water is submerged over the agarwood wood chips, then heat the dry distillation reaction kettle, after the water in the dry distillation reaction kettle is evaporated to dryness, the mobile phone condenses the product and stands for stratification, Separating the upper layer of agarwood essential oil A;

[0028] (4) take out the agarwood wood chips in the dry distillation reactor, and dry after cleaning;

[0029] (5) Then the agarwood wood chips processed in step (4) are further pulverized to obtain agarwood powder;

[0030] (6) Add compound enzyme and...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com