A magnetic fluid double suspension dynamic pressure bearing

A technology of dynamic pressure bearings and magnetic fluids, which is applied to bearings, shafts, bearings, bearing cooling, etc., can solve the problems of inability to support the shaft and reduce the load-carrying capacity, and achieve the effect of improving the load-bearing capacity and stiffness and improving working conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment example

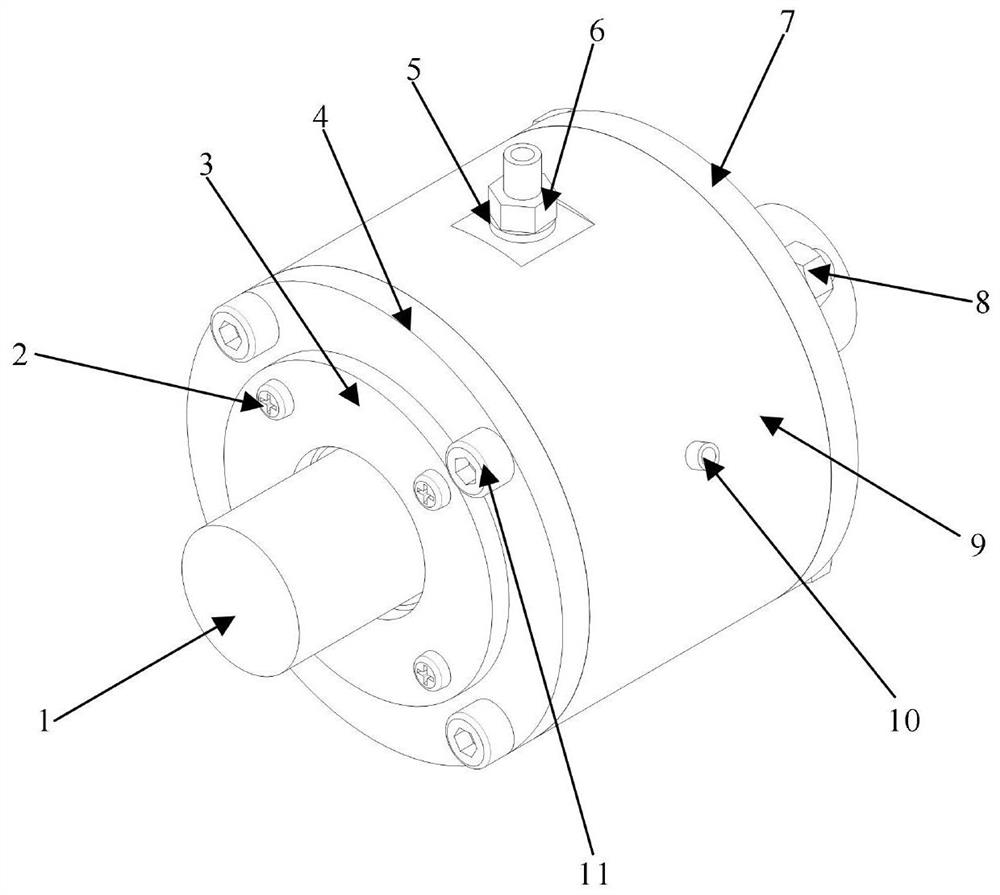

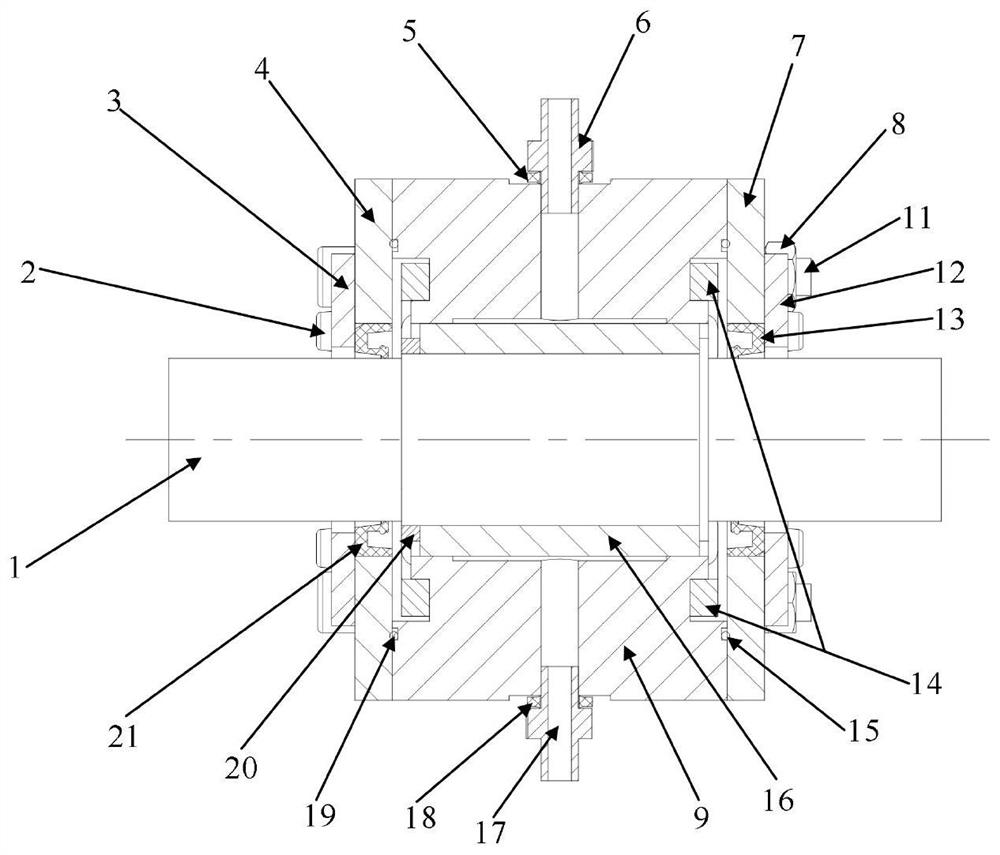

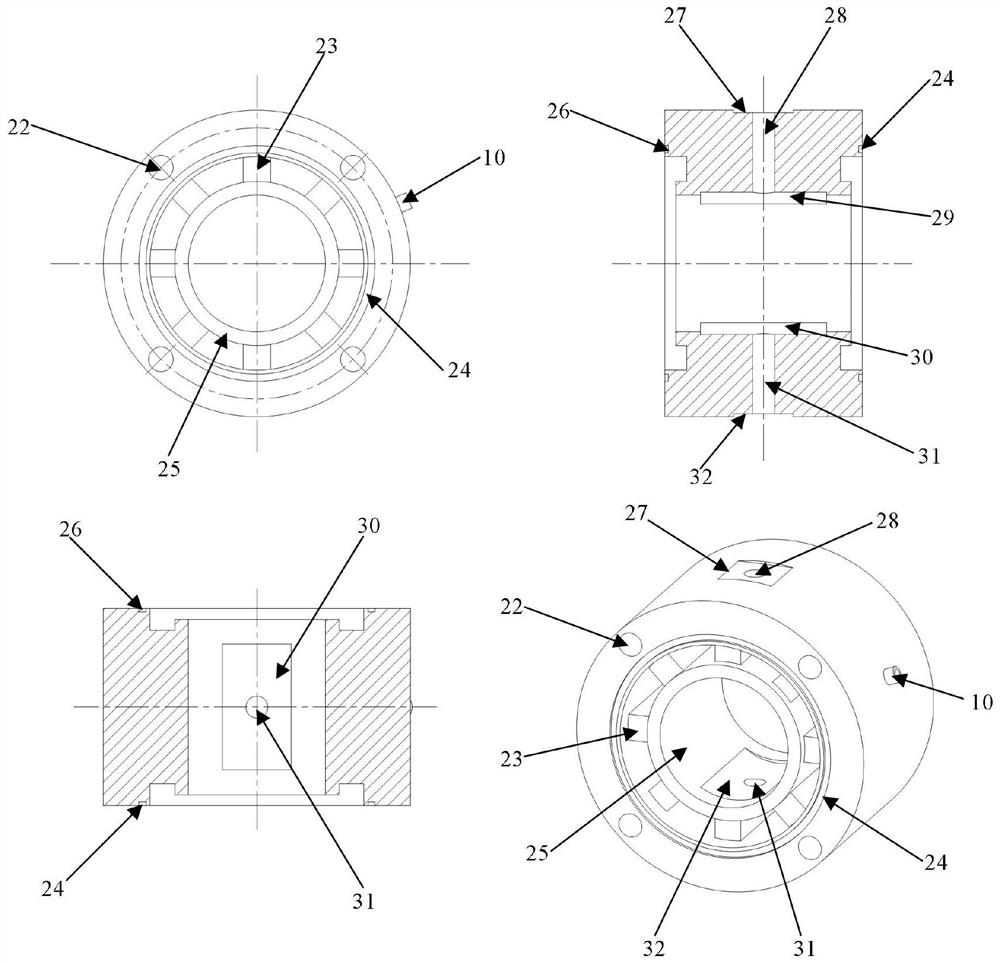

[0027] Below in conjunction with accompanying drawing, the present invention is described in detail: the diameter of journal 37 of stepped shaft 1 is 35mm and the length is 50mm, the diameter of journal B38 is 37mm and the length is 64mm, the diameter of journal 39 is 43.5mm and the length is 2mm, and the diameter of journal 40 is 2mm. The length of 35mm is 50mm; the first small end cap 3 is a rotating body with an outer diameter of 80mm, an inner diameter of 40mm, and a thickness of 5mm. The distance between the centers is 33mm, and the structural dimensions of the second small end cap 12 are symmetrically equal to the structural dimensions of the first small end cap 3; The diameter of the installation through hole 33 is 9mm, the distance between the center of the installation through hole 33 and the center of the first large end cap 4 is 49.5mm, the diameter of the threaded blind hole 34 is 5mm, and the depth is 5mm. The distance between the centers of the large end caps 4 i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com