Method for detecting moisture contents of explosion beads for cigarettes

A detection method and explosive bead technology, applied in the field of cigarette materials, can solve the problems of different diameters, rubber thicknesses, difficult detection of moisture content, low moisture content, etc., and achieve the effects of suitable sensitivity, simple structure and low signal-to-noise ratio.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

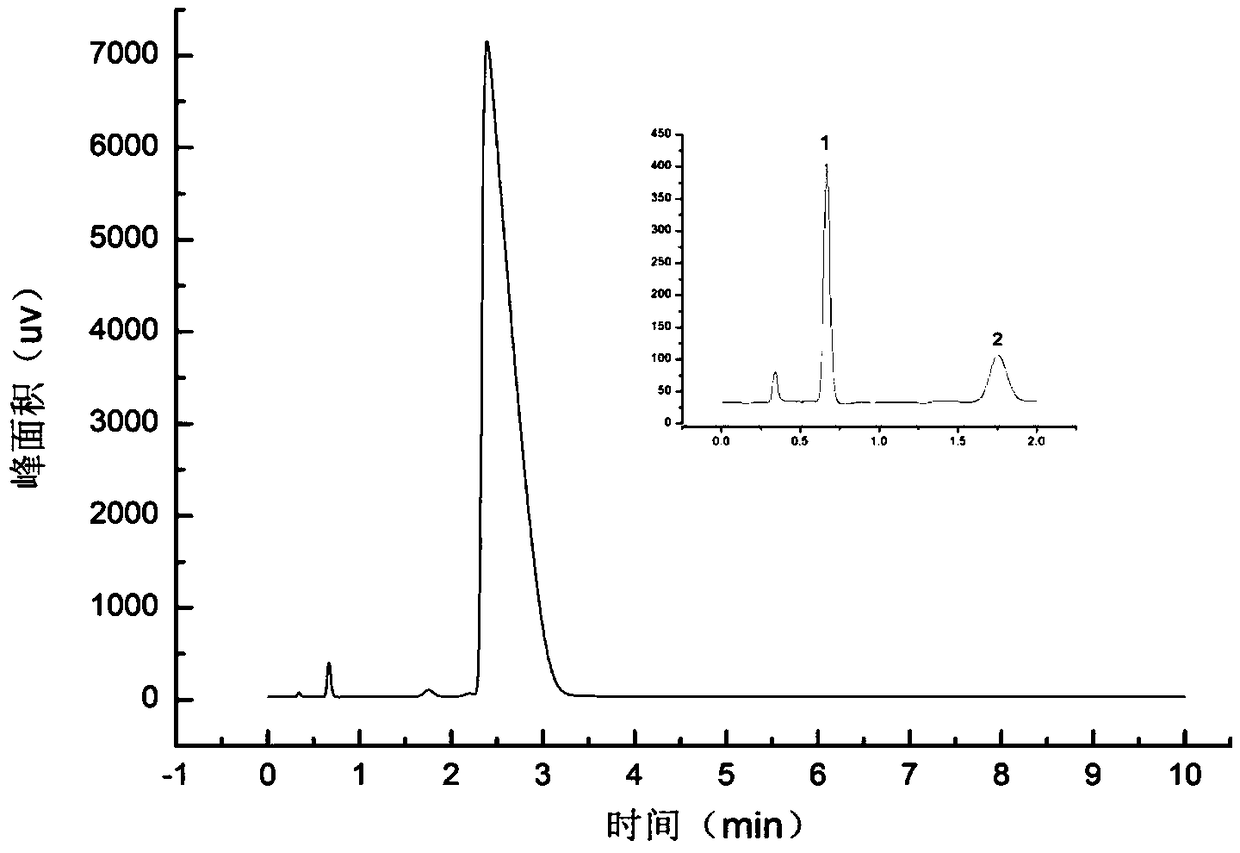

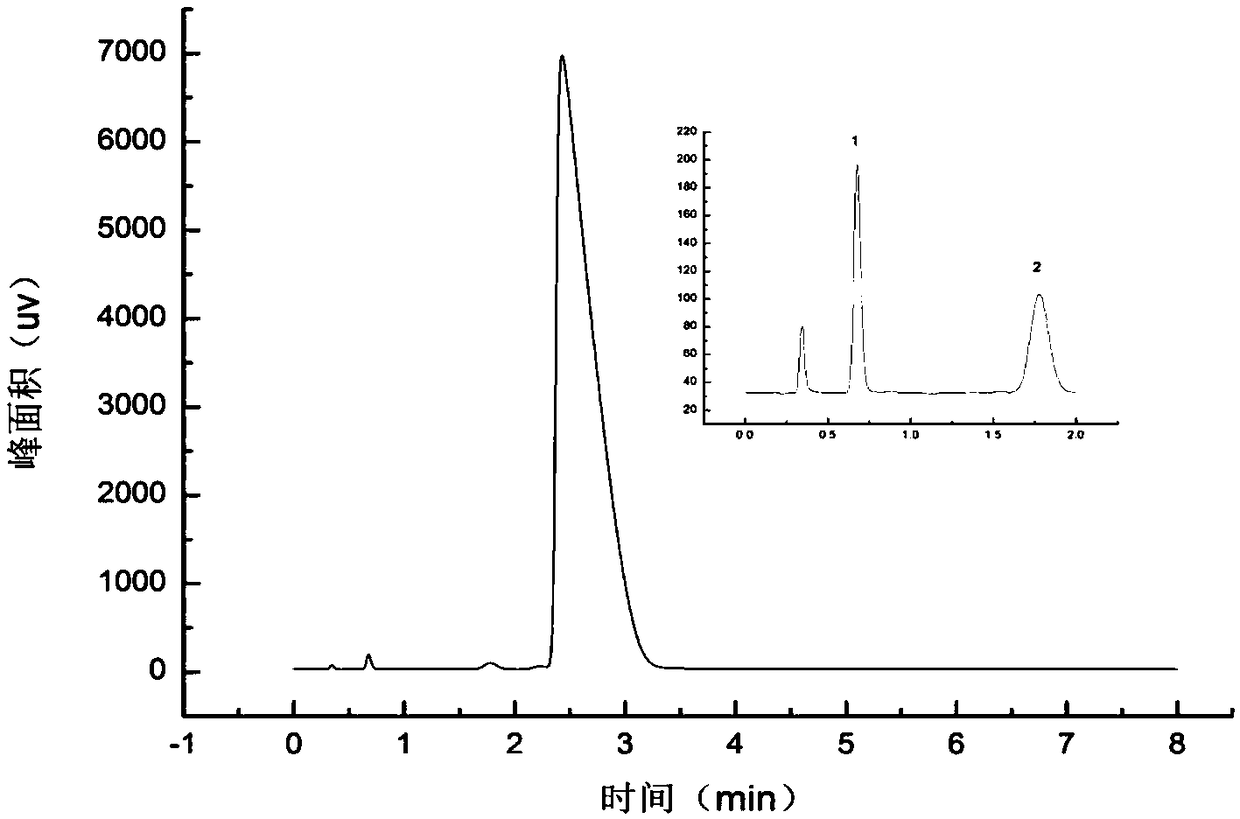

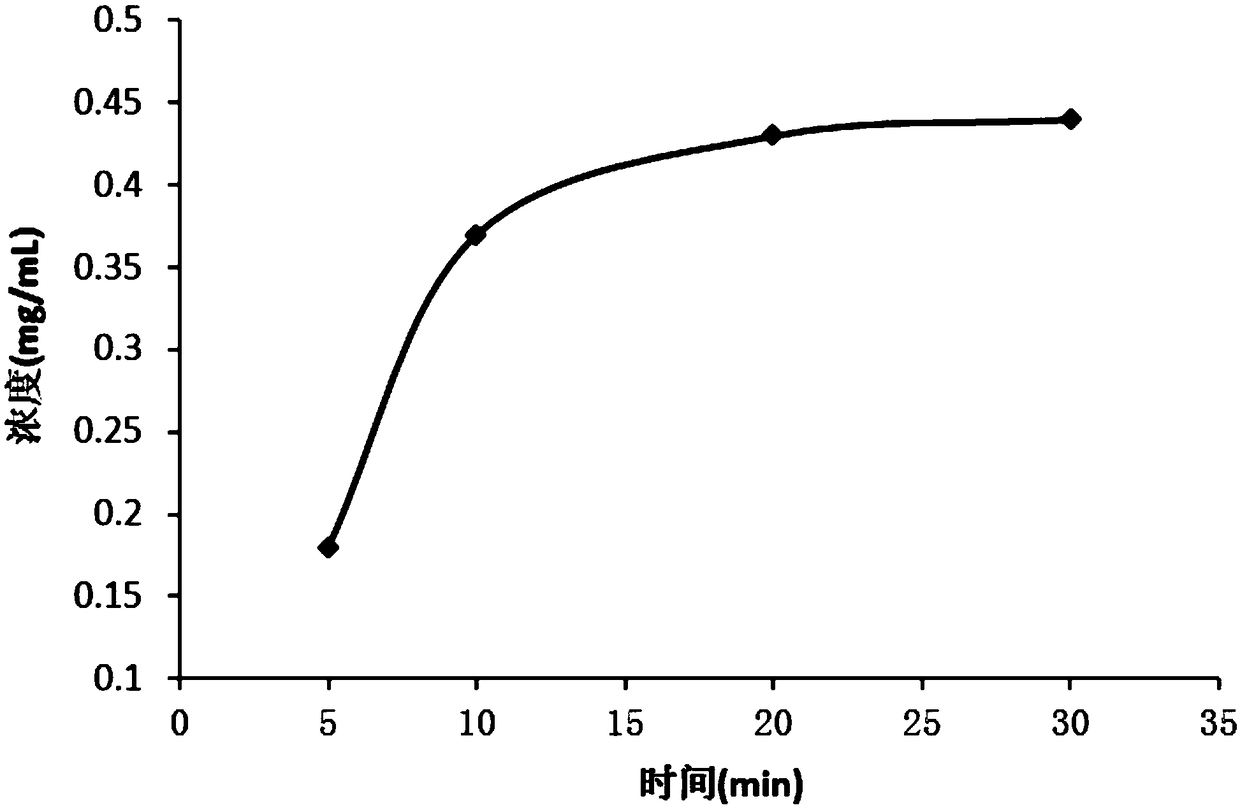

[0031] The invention provides a method for detecting the moisture content of the quick-fried pearls for cigarettes. The moisture content in the quick-fired pearls is obtained through capillary column separation, gas chromatography-thermal conductivity detector (GC-TCD) analysis, and internal standard method for quantification. The limit of quantification, standard addition recovery, and intraday (inter) precision experiments were verified for the method. The results showed that the recoveries of high, medium and low standards were between 98.95% and 104.48%; the quantitative limit of the method was 0.0577mg / mL ; The intraday precision is 3.47%, and the interday precision is 4.05%.

[0032] A method for detecting the moisture content of the quick-fried beads for cigarettes of the present invention comprises the following steps:

[0033] S1. Configuration of standard curve

[0034] Prepare anhydrous ethanol (internal standard) / isopropanol extract at a volume ratio of 1:333; wei...

PUM

| Property | Measurement | Unit |

|---|---|---|

| recovery rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com