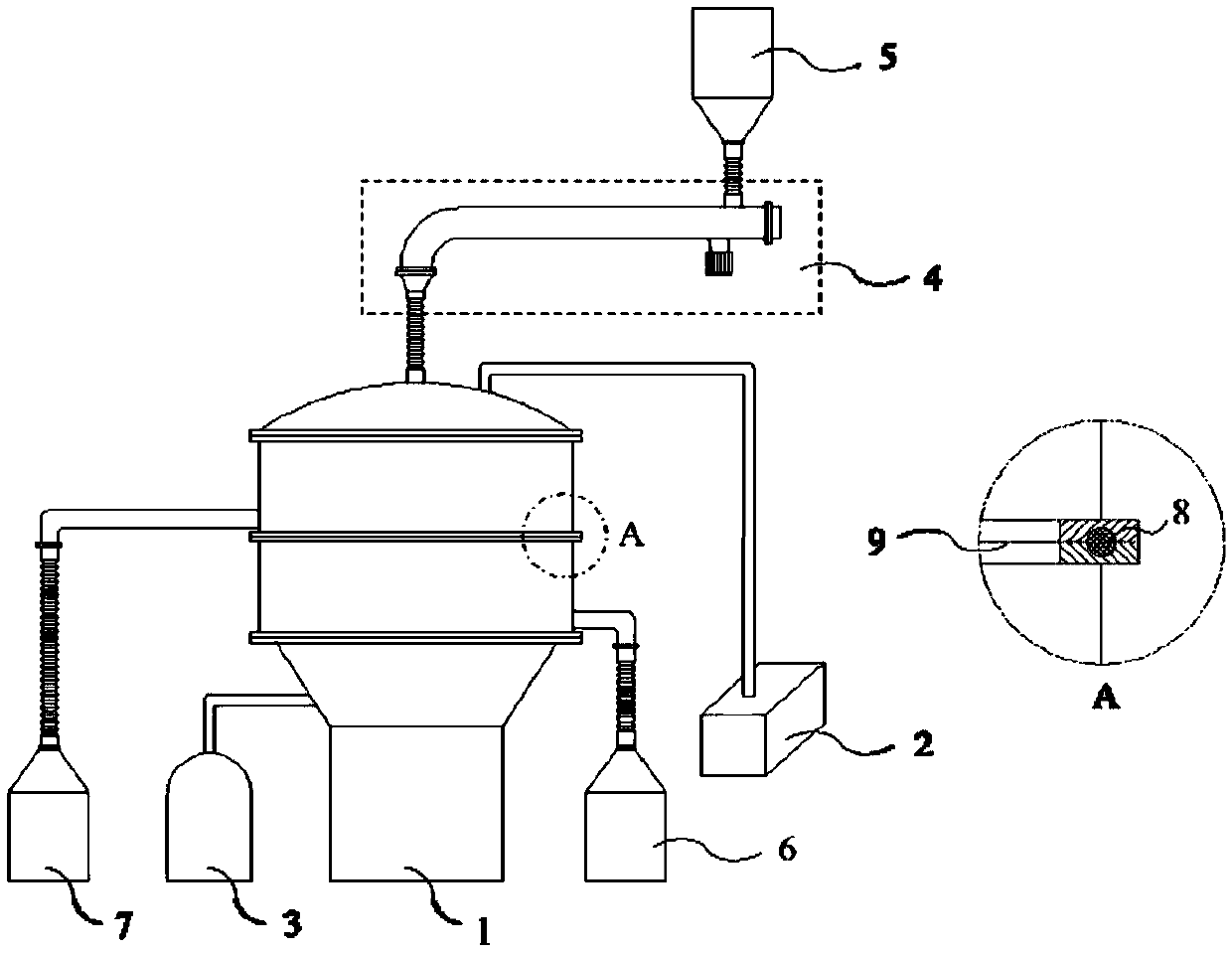

Screening device for pure high-temperature alloy powder

A screening device and high temperature alloy technology, applied in the field of powder metallurgy, can solve the problems of secondary pollution and high level, and achieve the effects of avoiding strong impact, simple device structure and good sealing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] 150kgGH4169 alloy powder was used for sieving test, the sieving device was vacuumed until the vacuum degree was 6.0Pa, and argon gas was filled at a rate of 30L / min, and the high-temperature alloy metal powder powder collection tank prepared by vacuum induction was fed into the electromagnetic feeding tank. The upper end of the system is connected, the feeding speed is selected as 2kg / min, and the vibrating screening system is turned on. After the continuous screening is completed, the classified powder storage tank is sealed and stored for later use.

Embodiment 2

[0034] 240kgGH3536 alloy powder was used for screening test, the screening device was vacuumed until the vacuum degree was 7.5Pa, filled with argon gas at a rate of 50L / min, and the superalloy metal powder powder collection tank prepared by vacuum induction was fed into the electromagnetic feeding tank. The upper end of the system is connected, the feeding speed is selected to be 4kg / min, and the vibrating screening system is turned on. After the continuous screening is completed, the classified powder storage tank is sealed and stored for later use.

Embodiment 3

[0036] The sieving test was carried out with 180kg of FGH95 alloy powder, and the sieving device was vacuumed until the vacuum degree was 8.0Pa, and argon gas was filled at a rate of 90L / min, and the high-temperature alloy metal powder powder collection tank prepared by vacuum induction and electromagnetic feeding The upper end of the system is connected, the feeding speed is selected as 6kg / min, and the vibrating screening system is turned on. After the continuous screening is completed, the classified powder storage tank is sealed and stored for later use.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com