Kitchen waste treatment system and method

A kitchen waste and treatment system technology, applied in waste treatment, biomass post-processing, biomass pretreatment, etc., can solve problems such as human health hazards, increase antibiotic drug residues, homologous pollution, etc., to prevent The effect of secondary pollution of the environment, realization of resource utilization, and improvement of operational stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

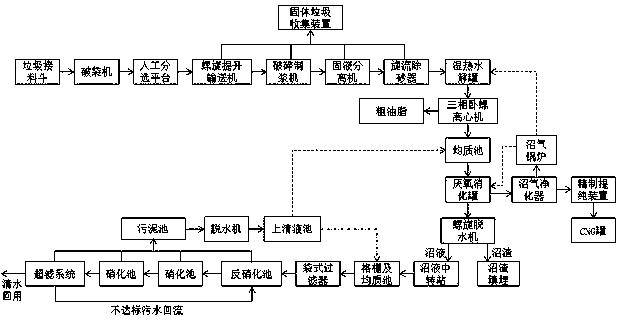

[0040] see figure 1 , a food waste treatment system, the food waste treatment system includes a food waste digestion system and a biogas slurry treatment system, the food waste digestion system includes a garbage receiving hopper, a bag breaking machine, a manual sorting platform, a spiral lifting Conveyor, crushing and pulping machine, solid-liquid separator, cyclone desander, wet thermal hydrolysis tank, three-phase decanter centrifuge, homogenizing tank, anaerobic digestion tank, screw dehydrator, biogas slurry transfer station, solid waste Collection devices, biogas purifiers, refining and purification devices, CNG tanks and biogas boilers;

[0041] The garbage receiving hopper receives the food waste carried by the food waste transport vehicle and transports it to the bag breaker through the screw conveyor;

[0042] The bag breaking machine breaks the garbage and sends it to the manual sorting platform;

[0043] The manual sorting platform manually sorts the food waste,...

Embodiment 2

[0063] Another embodiment 2 of the present invention can be used as a further improvement of embodiment 1. In the homogeneous tank, the solid content of the mixed slurry is adjusted to 8%, and the supernatant after biogas slurry treatment is used for the adjustment liquid. There is a conical bottom to settle the sediment, and the sand is regularly discharged through the sand discharge port. The slurry storage device is equipped with a warming and heat preservation device. The internal temperature of the slurry storage device is 35-38°C, and the pH value of the liquid is controlled at 6.5-8.5. Controlled by the online monitoring device, the slurry stays in the slurry storage device for 1 day.

Embodiment 3

[0065] Another third embodiment of the present invention can be used as a further improvement of the first and second embodiments. The anaerobic digestion tank is set to adopt warm anaerobic fermentation, the heating temperature is 35°C, and the carbon-to-nitrogen ratio of the material (C:N) Control within the range of 20:1-25:1; the anaerobic digestion tank is a cylindrical fermenter with a flat bottom and a concrete sealed structure. The upper part of the fermenter is equipped with a scum removal device, and the top of the fermenter is equipped with a biogas hood , collect biogas and transport it to the biogas treatment process. The slurry stays in the fermentation tank for 21 days. The outer surface of the anaerobic digestion tank is equipped with thermal insulation devices and temperature compensation devices. The heat required by the temperature compensation device is provided by the biogas boiler.

[0066] The invention also specifically discloses a method for disposing o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com