Weighing medicine box

A medicine box and weighing technology, which is applied in the direction of weighing, weighing equipment testing/calibration, capping, etc., can solve the problems of inaccurate weighing, inconvenient use, and increased workload of operators, and achieve convenient calibration and operation. Easy Calibration Effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0084] In order to have a clearer understanding of the technical solutions, objectives and effects of the present invention, the specific implementation manners of the present invention will now be described with reference to the accompanying drawings.

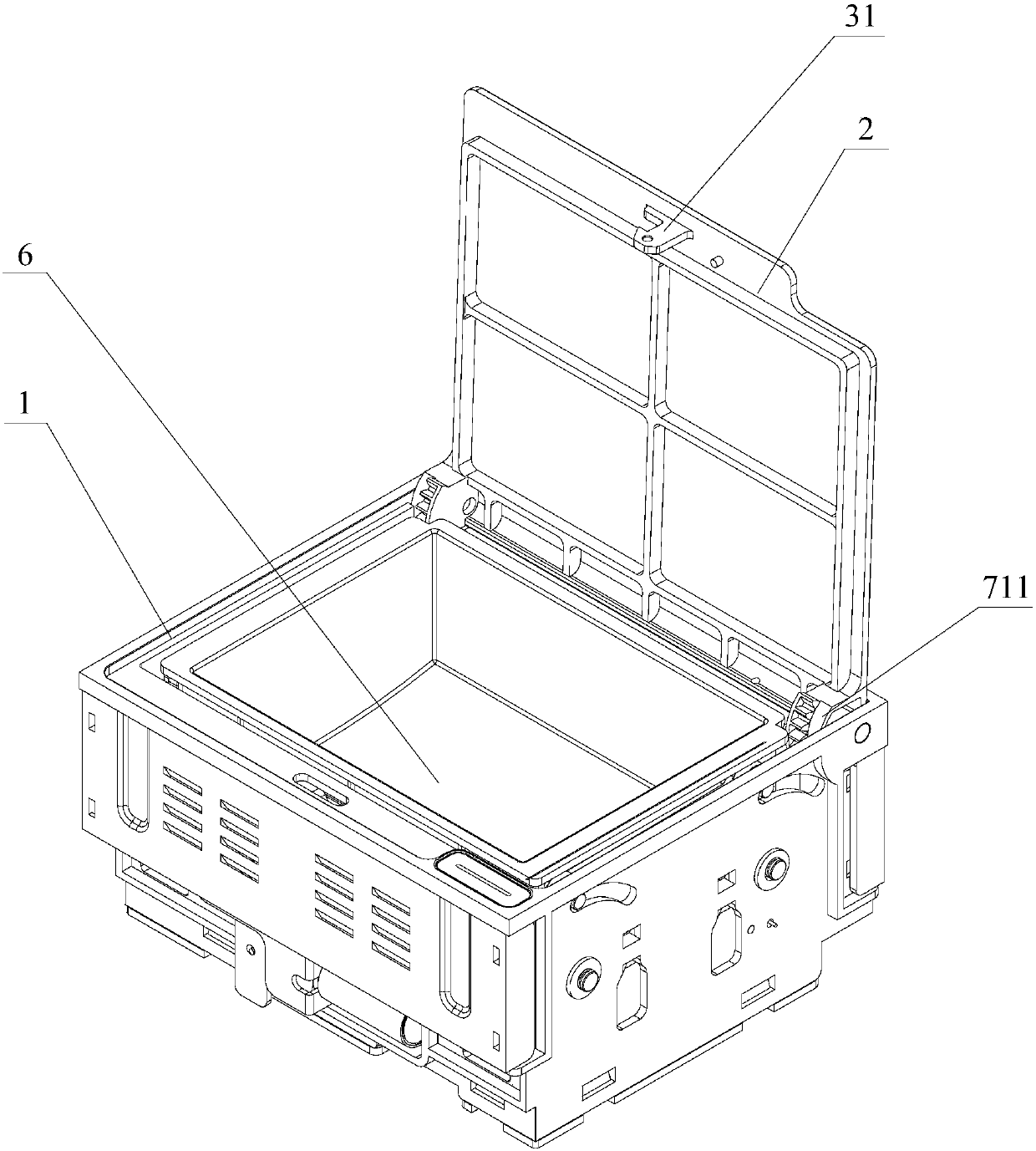

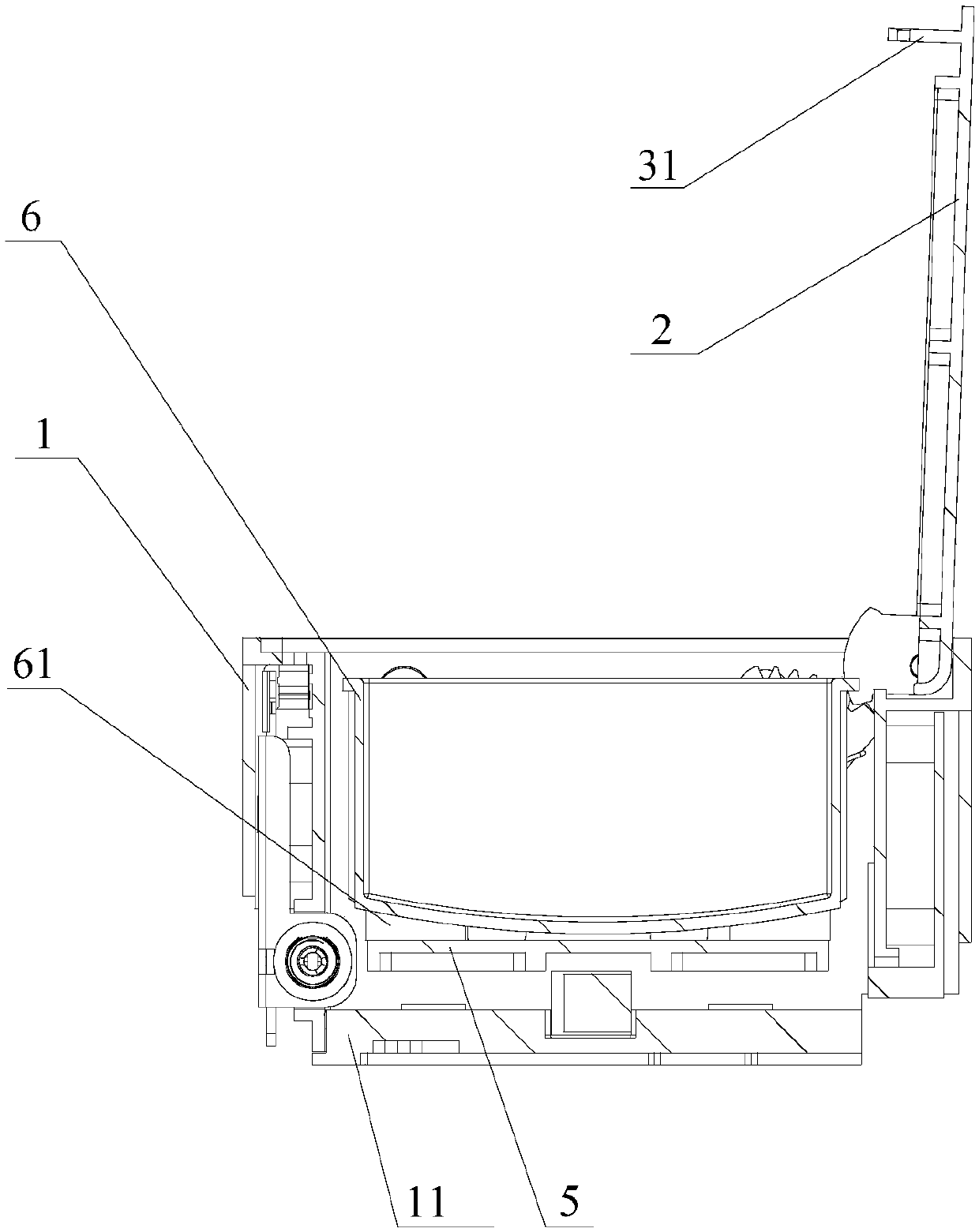

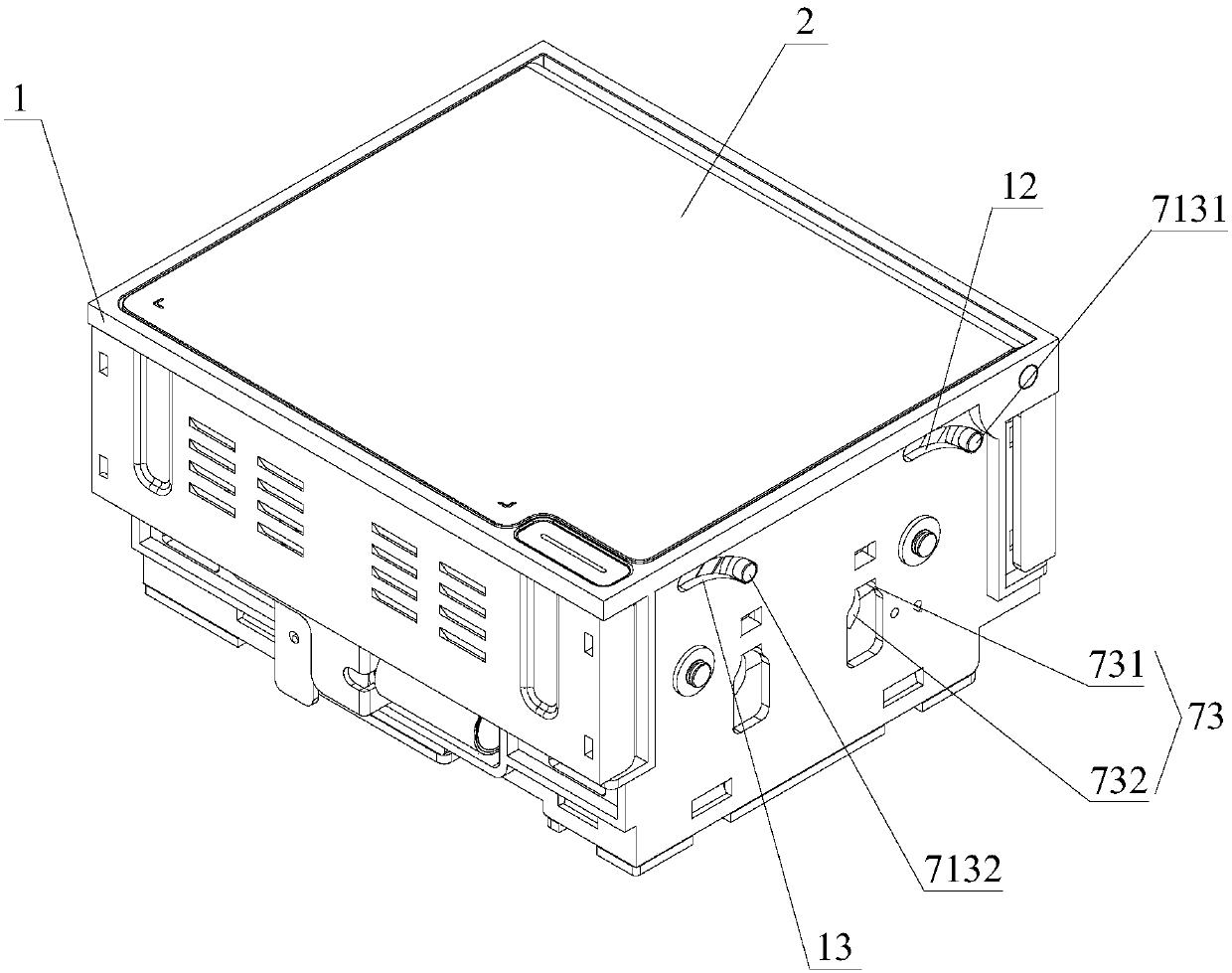

[0085] Such as Figure 1 to Figure 18 As shown, the present invention provides a weighing medicine box, wherein the weighing medicine box comprises an outer box 1 with an open top, that is, the outer box 1 is a rectangular box-shaped structure with an open top, and the top cover of the outer box 1 is provided with a box Cover 2, the box cover 2 is used to close the top opening of the outer box 1, the first side of the box cover 2 is pivotally connected with the first side of the outer box 1, and the second side of the box cover 2 is connected to the outer box through the switch device 3 1, it can be understood that the box cover 2 can be opened and closed on the top of the outer box 1, and the rear side of the box cover 2 is c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com