Scribing apparatus

A scribing and equipment technology, applied in glass manufacturing equipment, glass cutting devices, glass production, etc., can solve problems such as the inability to cut and bond substrates smoothly, and achieve the effect of accurate modification and easy cutting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

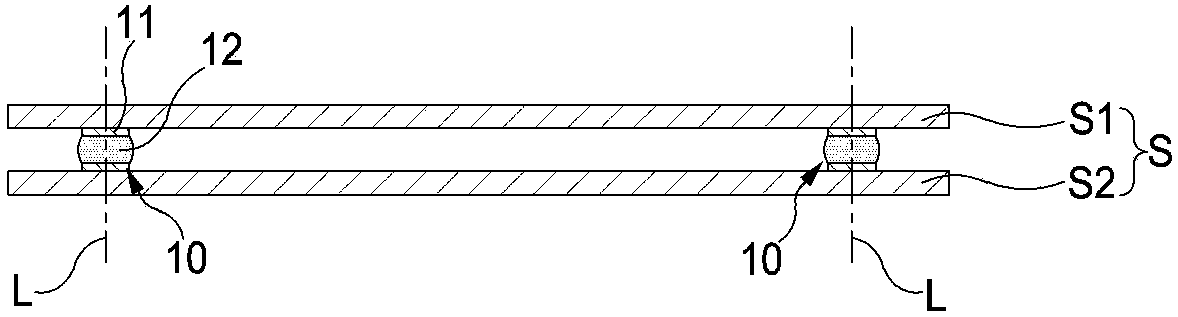

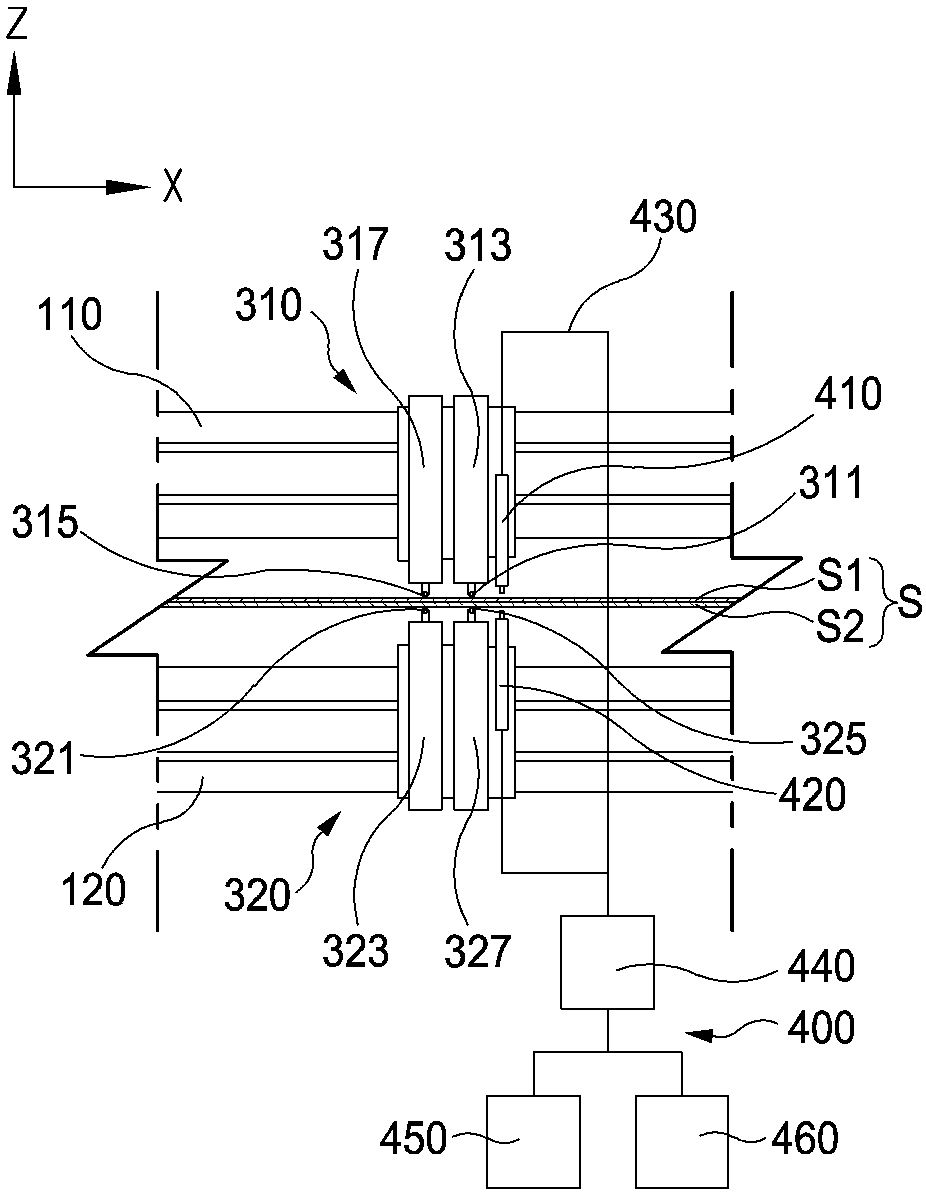

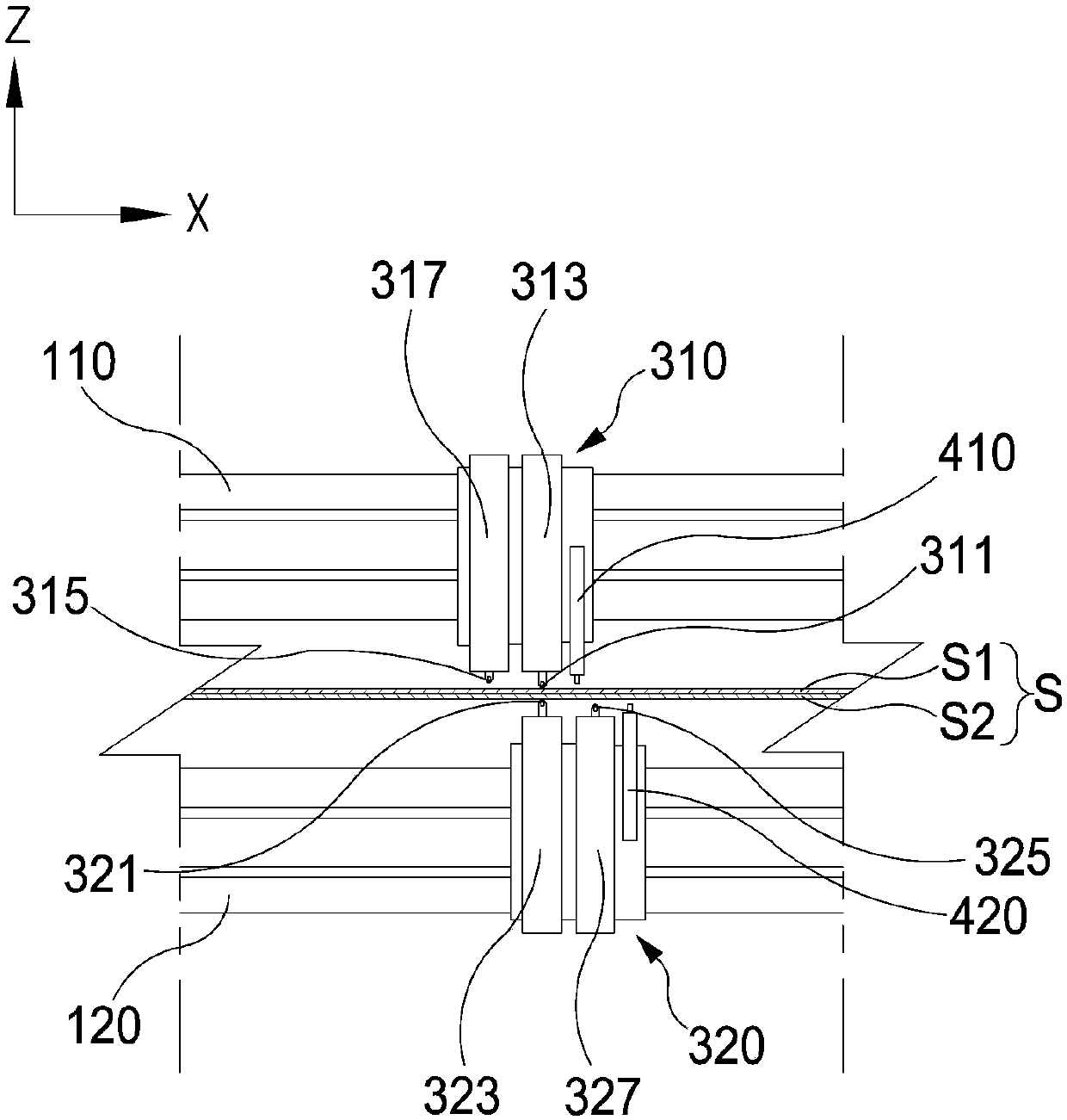

[0086] As in the first embodiment of the present invention, when there are multiple media 10 between the bonded substrates S, the first laser beam irradiation head 410 and the second laser beam irradiation head 420 move in the direction of the Z axis, and can sequentially irradiate A type of laser beam for a medium 11 and a second medium 12 .

[0087] The scribing apparatus in the first embodiment of the present invention irradiates a plurality of kinds of media 10 with laser beams respectively corresponding to kinds of a plurality of kinds of media 10 arranged in a predetermined pattern between bonded substrates S, so that at least a part of the media 10 is modified. , forming scribe lines on the bonded substrate S along the pattern of the medium 10 to cut the bonded substrate S. Thereby, it becomes easy to cut the bonded board|substrate S together with the medium 10 provided between the bonded board|substrates S. As shown in FIG.

[0088] Below, refer to Figure 10 , to de...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com