Manufacturing process of high-filling easy-to-cut iron-based amorphous nanocrystalline alloy iron core

A nanocrystalline alloy and iron-based amorphous technology, which is applied in the field of iron core processing, can solve the problems that the polymer resin glue is not easy to fill up, and the amorphous/nanocrystalline alloy debris is generated, so as to achieve easy cutting, easy manufacturing, Efficient effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

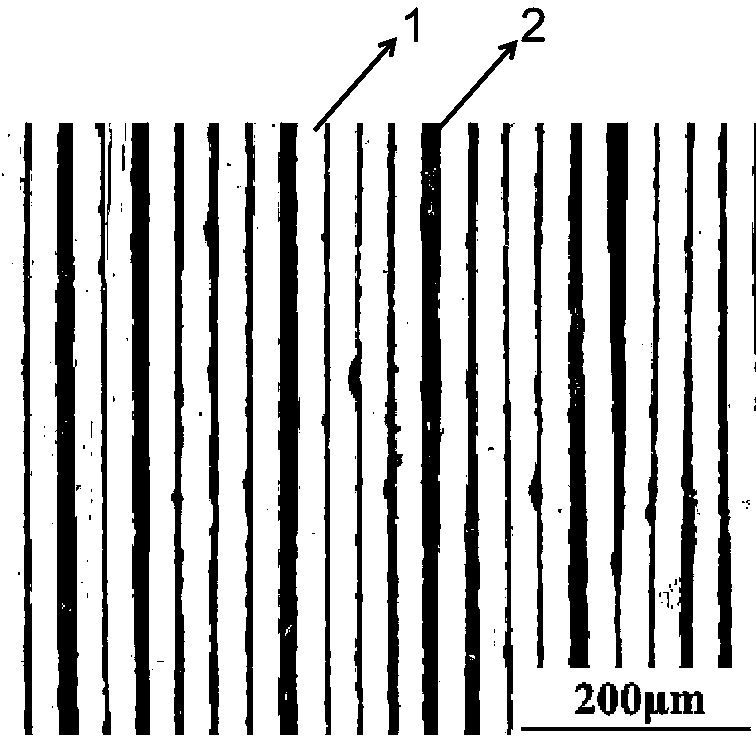

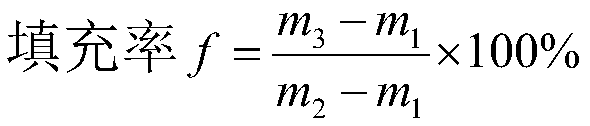

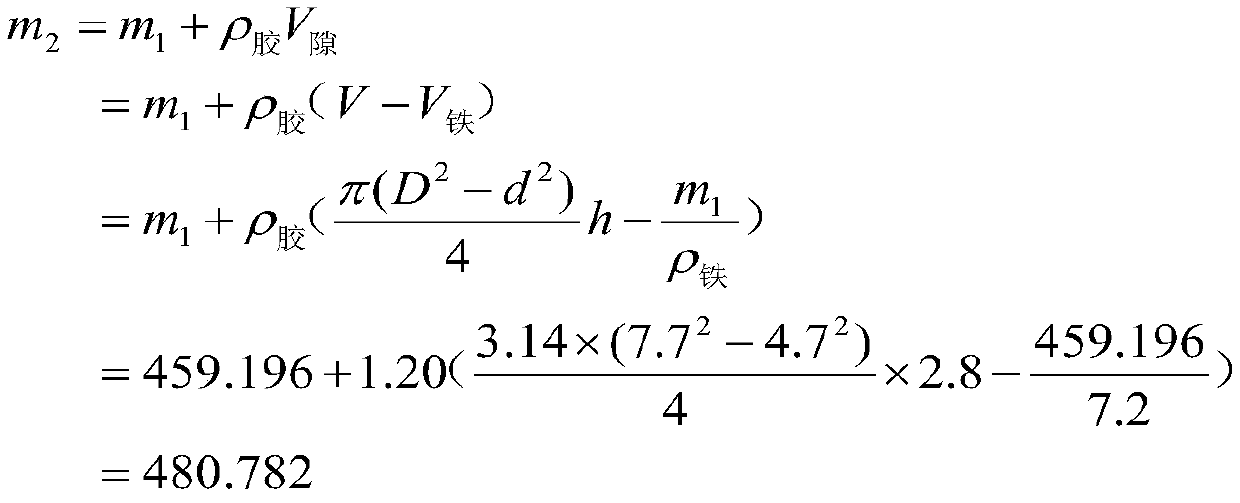

[0034] Specific embodiment (1): obtain a ring-shaped iron core through conventional processes such as smelting, spraying amorphous thin strips, winding, vacuum annealing, and its size is 47 / 77 / 28 (inner diameter 47mm, outer diameter 77mm, height 28mm), mass m 1 is 459.196 grams;

[0035] S2. Put the iron core in S1 into the working room. The working room is a cylindrical container with a size slightly larger than the iron core. Add polymer resin glue, epoxy resin is used for the polymer resin glue, and the iron core is immersed, and the iron core is immersed in the polymer resin glue for 2cm.

[0036] S3. Put the working room together with the iron core and epoxy resin into the high-speed centrifuge of the supergravity machine. The supergravity machine is a high-speed centrifuge with a large material barrel. Rotate for 5min;

[0037] S4, take out the studio, pour out the remaining polymer resin glue, and take out the iron core;

[0038] S5. Place the iron core on a flat wo...

specific Embodiment ( 2

[0042] Specific embodiment (two): obtain a ring-shaped iron core through conventional processes such as smelting, spraying amorphous thin strips, winding, vacuum annealing, and its size is 47 / 77 / 28 (inner diameter 47mm, outer diameter 77mm, height 28mm), mass m 1 is 459.192 grams;

[0043] S2. Put the iron core in S1 into the working room. The working room is a cylindrical container with a size slightly larger than the iron core. Add polymer resin glue, epoxy resin is used for the polymer resin glue, and the iron core is immersed, and the iron core is immersed in the polymer resin glue for 3cm.

[0044] S3. Put the working room together with the iron core and epoxy resin into the high-speed centrifuge of the supergravity machine. The supergravity machine is a high-speed centrifuge with a large material barrel. Rotate for 8min;

[0045] S4, take out the studio, pour out the remaining polymer resin glue, and take out the iron core;

[0046] S5. Place the iron core on a flat ...

specific Embodiment ( 3

[0050]Specific embodiment (three): obtain an annular iron core through conventional processes such as smelting, spraying amorphous thin strips, winding, vacuum annealing, and its size is 47 / 77 / 28 (inner diameter 47mm, outer diameter 77mm, height 28mm), mass m 1 is 459.198 grams;

[0051] S2. Put the iron core in S1 into the working room. The working room is a cylindrical container with a size slightly larger than the iron core. Add polymer resin glue, epoxy resin is used for the polymer resin glue, and the iron core is immersed, and the iron core is immersed in the polymer resin glue for 2.5cm.

[0052] S3. Put the working room together with the iron core and epoxy resin into the high-speed centrifuge of the supergravity machine. The supergravity machine is a high-speed centrifuge with a large material barrel. Rotate for 10min;

[0053] S4, take out the studio, pour out the remaining polymer resin glue, and take out the iron core;

[0054] S5. Place the iron core on a flat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The inside diameter of | aaaaa | aaaaa |

| Outer diameter | aaaaa | aaaaa |

| Height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com