A kind of cardanol modified water-based epoxy curing agent and preparation method thereof

A technology of water-based epoxy and water-based epoxy resin, applied in epoxy resin coatings, coatings, etc., can solve the problems of poor mechanical properties and thermal stability of coating films, achieve low VOC content, low synthesis temperature, and good impact resistance sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

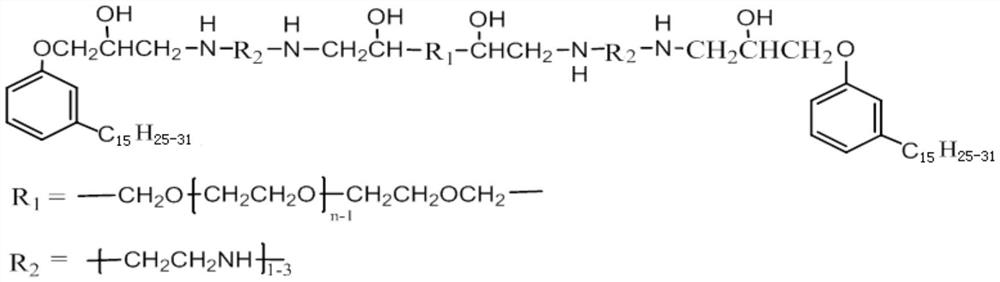

[0033] Embodiment 1: A kind of cardanol modified waterborne epoxy resin curing agent and preparation method thereof

[0034] Prepare cardanol modified water-based epoxy resin curing agent according to the following steps:

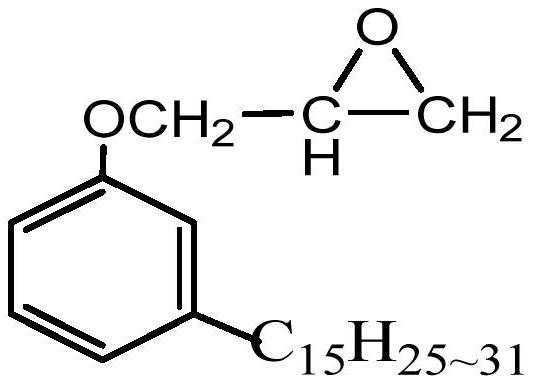

[0035] Add 60g (0.2mol) of cardanol, 74g (0.8mol) of epichlorohydrin, 40g (0.4mol) of 40% NaOH aqueous solution, and 0.3g of benzyltriethylammonium chloride into a four-necked flask, and heat up to 70°C. After reacting for 6 hours, vacuum distillation (60°C, -0.09MPa) recovered excess epichlorohydrin and water, and the product was centrifugally filtered to obtain cardanol glycidyl ether (CGE) for use;

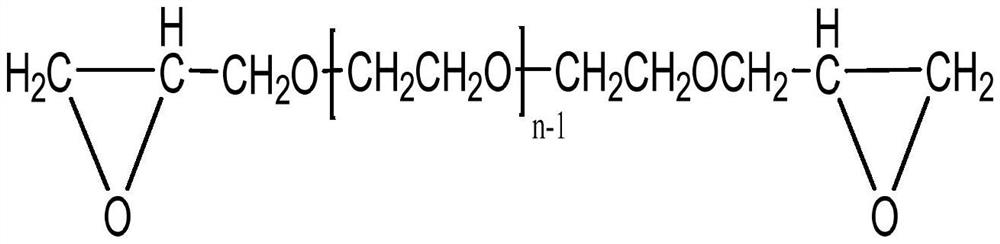

[0036] Weigh 40g of PEG400 (0.1mol), 37g (0.4mol) of epichlorohydrin and 0.3g of boron trifluoride diethyl ether in a four-neck flask, heat up to 60°C for 3 hours, add 30g (0.3mol) of 40% NaOH aqueous solution, 60 Continue to react at ℃ for 3 hours, the product is recovered under reduced pressure (60℃, -0.09MPa) to recover excess epichlorohydrin and water, ...

Embodiment 2

[0046] Embodiment 2: A kind of cardanol modified waterborne epoxy resin curing agent and preparation method thereof

[0047]Prepare cardanol modified water-based epoxy resin curing agent according to the following steps:

[0048] Add 60g (0.2mol) of cardanol, 74g (0.8mol) of epichlorohydrin, 42g (0.3mol) of 40% KOH aqueous solution, and 0.4g of tetrabutylammonium bromide into a four-necked flask, raise the temperature to 70°C, and react for 6h Afterwards, vacuum distillation (60°C, -0.09MPa) recovers excess epichlorohydrin and moisture, and the product is centrifugally filtered to obtain cardanol glycidyl ether (CGE) for use;

[0049] Weigh 60g of PEG600 (0.1mol), 37g (0.4mol) of epichlorohydrin and 0.4g of boron trifluoride diethyl ether in a four-neck flask, heat up to 60°C for 3 hours, add 30g (0.3mol) of 40% NaOH aqueous solution, 60 Continue to react at ℃ for 3 hours, the product is recovered under reduced pressure (60℃, -0.09MPa) to recover excess epichlorohydrin and wa...

Embodiment 3

[0051] Embodiment 3: A kind of cardanol modified waterborne epoxy resin curing agent and preparation method thereof

[0052] Prepare cardanol modified water-based epoxy resin curing agent according to the following steps:

[0053] Add 60g (0.2mol) of cardanol, 56g (0.6mol) of epichlorohydrin, 20g (0.2mol) of 40% NaOH aqueous solution, and 0.25g of benzyltriethylammonium chloride into a four-necked flask, and heat up to 70°C. After reacting for 6 hours, vacuum distillation (60°C, -0.09MPa) recovered excess epichlorohydrin and water, and the product was centrifugally filtered to obtain cardanol glycidyl ether (CGE) for use;

[0054] Weigh 20g of PEG400 (0.05mol), 30g of PEG600 (0.05mol), 37g (0.4mol) of epichlorohydrin and 0.2g of boron trifluoride ether in a four-neck flask, heat up to 60°C for 3 hours, add 30g of 40% NaOH aqueous solution (0.3mol), continue to react at 60°C for 3h, recover excess epichlorohydrin and water from the product under reduced pressure (60°C, -0.09MP...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| impact strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com