Anode electric-conducting device used for aluminum electrolysis

A conductive device and aluminum electrolysis technology, applied in the field of conductive anode devices, can solve the problems of expanding the local cracking failure of the aluminum-steel welding surface, reducing the service life of the explosive welding block, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

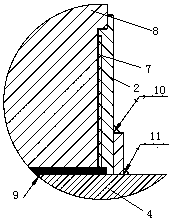

Embodiment 1

[0033] 1.1 Preparation method of the device

[0034] Take a cylindrical aluminum rod as a conductive guide rod, turn a section of external thread at one end of the guide rod, and make an undercut at the top of the external thread. Prepare a steel sleeve 2 with an internal thread that can cooperate with the aforementioned external thread, and screw the steel sleeve 2 on the threaded section of the guide rod. Make pattern at the corresponding position on the upper surface of steel claw crossbeam 4 in advance, and the most convenient way is to turn and go out annular pattern. The beam 4 is welded to the full cross-section of the steel claw head 5, for example, by friction welding. After the steel claw is prepared, the guide rod is combined with the upper surface of the steel claw beam 4 by friction welding, and the aluminum released during friction welding is filled in the steel sleeve 2 Between the lower end surface and the upper surface of the steel claw beam 4. Put the trans...

Embodiment 2

[0038] 2.1 Preparation method of the device

[0039] The preparation method of this embodiment is basically the same as that of Example 1, the difference is that this embodiment does not set an excessive steel sleeve, but after the guide rod and the upper surface of the steel claw beam 4 are friction welded together, the lower part of the steel sleeve 2 is directly Ring welding is carried out between the outer wall and the upper surface of the steel claw beam 4 and fixed.

[0040] 2.2 Structure of the device

[0041] The structure of the embodiment is basically with the attached figure 1 , but it is not provided with an excessive steel sleeve 3.

[0042] The above two embodiments are applicable to newly prepared conductive devices, and it can be known from the above description that the guide rod of the present invention is an integral component.

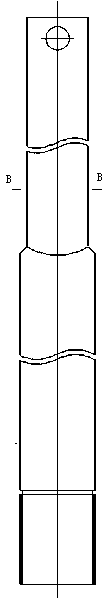

Embodiment 3

[0044] 3.1 Preparation method of the device

[0045] The guide bar of the old conductive device after service failure is sawed off to be the upper guide bar 1 for use, and the upper guide bar 1 is a square section. Take a section of cylindrical aluminum rod as the conductive lower guide rod 8, turn a section of external thread at the lower end of the lower guide rod 8, and make an undercut at the top of the external thread. Prepare a steel sleeve 2 with an internal thread that can cooperate with the aforementioned external thread, and screw the steel sleeve 2 on the threaded section of the guide rod. Make pattern at the corresponding position on the upper surface of steel claw crossbeam 4 in advance, and the most convenient way is to turn and go out annular pattern. The beam 4 is welded to the full section of the steel claw head 5, and after the steel claw is prepared, the guide rod and the upper surface of the steel claw beam 4 are friction welded together, and the aluminum ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com