Asymmetric-structure in-situ ultrasonic anti-pollution membrane with piezoelectric material as support body and preparation method thereof

An asymmetric structure, piezoelectric material technology, applied in chemical instruments and methods, membrane technology, semi-permeable membrane separation, etc., to achieve the effect of slowing down the phenomenon of concentration polarization, slowing down accumulation, and ensuring accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

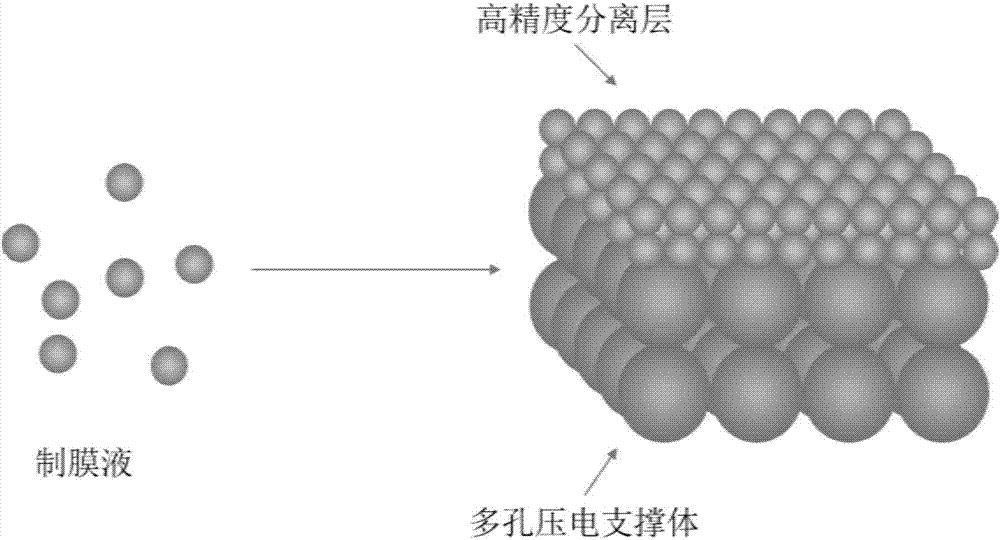

[0028] Example 1: Alumina in-situ ultrasonic microfiltration membrane supported by porous lead zirconate titanate and its preparation

[0029] The lead zirconate titanate powder (particle size 6-10um) is dry-pressed and calcined at 1200° C. for 4 hours to prepare a sheet-type porous lead zirconate titanate support body with an average pore diameter of 3000 nm. Disperse 15g of alumina (particle size 2-3um) in 100g of water, add 0.7g of nitric acid as a dispersant, and 0.5g of hydroxymethylcellulose, and disperse evenly to prepare a film-forming solution with a mass solid content of 15%. Coating on the surface of the lead zirconate titanate support for 3 minutes, raising the temperature of the wet film to 120°C and drying it in a hot air drying oven for 12 hours, then heating the dried film to 1050°C in the air, and calcining it for 4 hours to prepare a The average pore size of the layer structure is a microfiltration membrane of 1000nm. The asymmetric membrane was subjected to...

Embodiment 2

[0030] Example 2: Zirconia in-situ ultrasonic microfiltration membrane supported by porous lead zirconate titanate and its preparation

[0031] On the basis of the alumina microfiltration membrane with an average pore size of 1000nm prepared in Example 1, 20g of zirconia powder (particle size of 300nm) was dispersed in 100g of aqueous solution, 1g of polyethyleneimine was added as a dispersant, and 1.3g of ethylene glycol was added. Alcohol is used as a thickener, dispersed evenly to prepare a film-making solution with a mass solid content of 20%, coated on the surface of 1000nm alumina for 1min, and the wet film was heated to 100°C and dried in a hot air drying oven for 20 hours, and then dried The dried membrane was heated to 800° C. in air, and calcined for 1 hour to prepare a zirconia microfiltration membrane with a three-layer structure and an average pore diameter of 100 nm. The asymmetric membrane was subjected to high-voltage polarization in an air environment of 150° ...

Embodiment 3

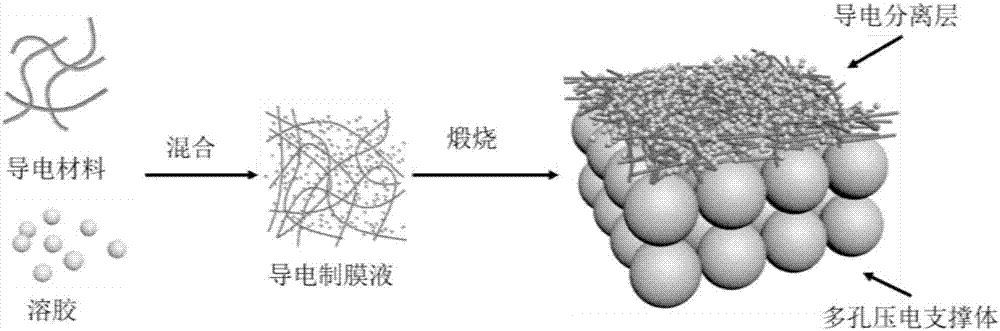

[0032] Example 3: Silicon oxide in-situ ultrasonic ultrafiltration membrane with porous lead zirconate titanate as support and its preparation

[0033]On the basis of the zirconia with an average pore size of 100nm prepared in Example 2, 15g of silicon oxide powder (30nm in particle size) was dispersed in 100g of deionized water, 1g of nitric acid was added as a dispersant, and 1.2g of polyvinyl alcohol was used as a thickener. Disperse evenly to prepare a membrane-forming solution with a mass solid content of 15%. Coat the surface of 100nm zirconia microfiltration membrane for 30s, raise the temperature of the wet membrane to 70°C and dry it in a hot air drying oven for 20 hours, then raise the temperature of the dried membrane to 700°C in the air, and calcinate it for 2 hours to prepare the four A silicon oxide ultrafiltration membrane with an average pore size of 10 nm in layer structure. The asymmetric membrane was subjected to high-voltage polarization in an insulating s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

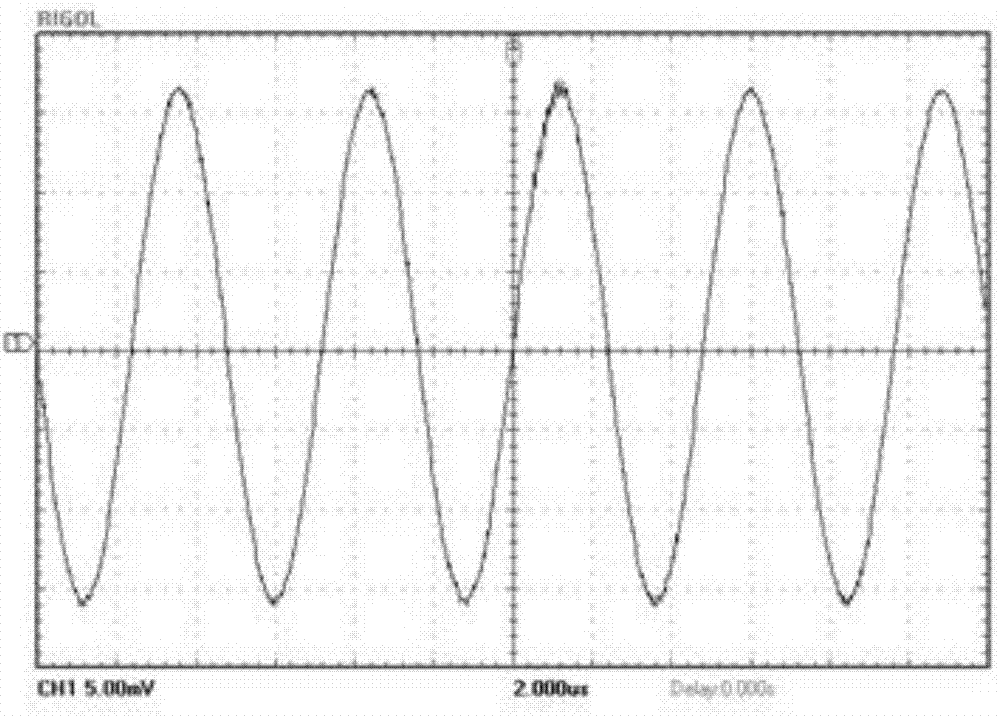

| Resonant frequency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com