Flexible substrate and preparation method and application thereof

A flexible substrate and substrate technology, applied in the field of flexible substrate preparation, can solve the problems of poor thermal stability and high water and oxygen permeability, and achieve the effect of simple process, wide source of materials, and blocking water and oxygen penetration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0028] A method for preparing a flexible substrate, comprising the following steps:

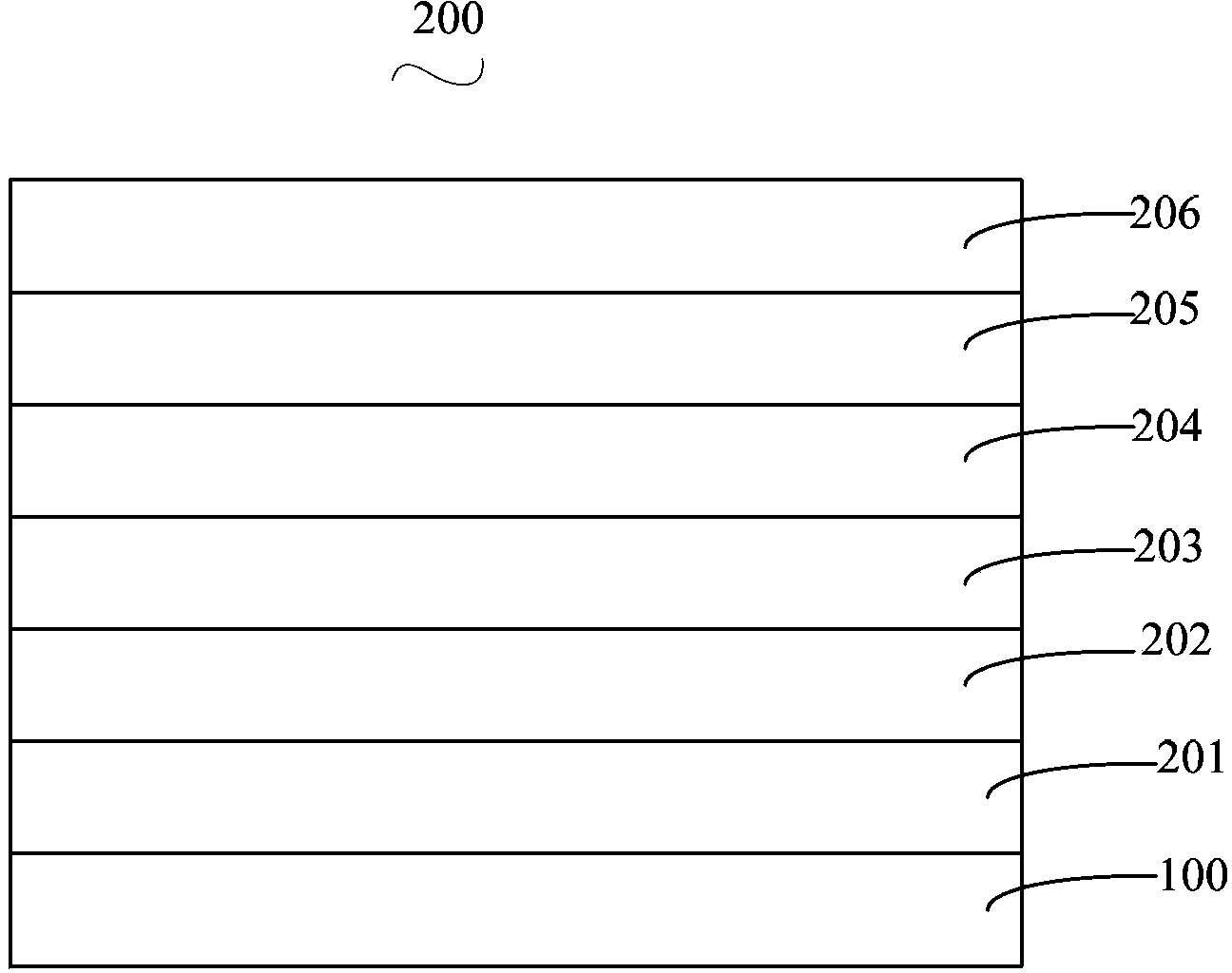

[0029] S10, to provide polymer film substrates, put the polymer film substrates into the vacuum coating system, at a vacuum degree of 10 -3 Pa~10 -5 Under the condition of Pa, the first metal aluminum layer is prepared by evaporating on one side of the polymer film substrate;

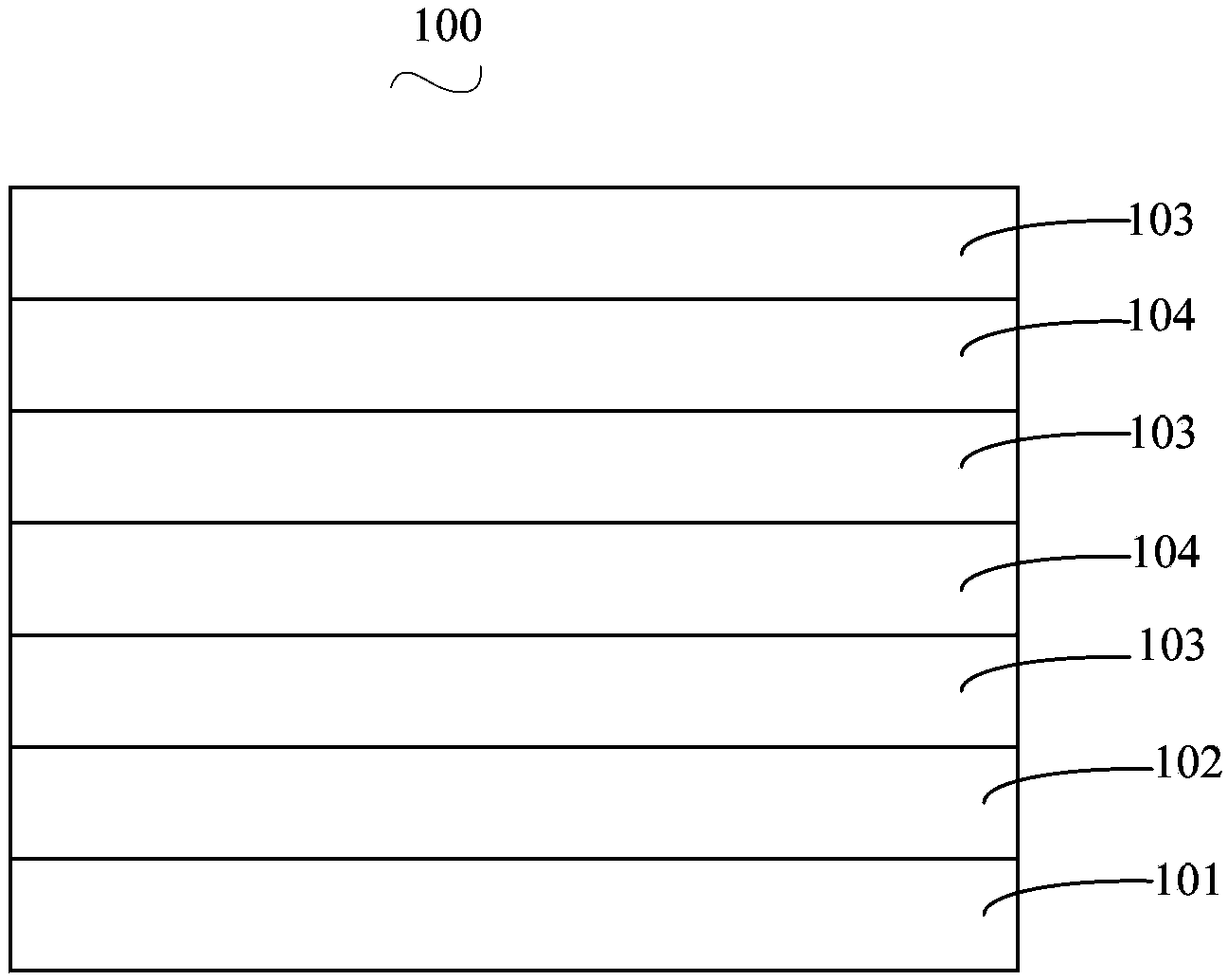

[0030] S20, then alternately vapor-depositing a second metal aluminum layer and a polyimide film layer on the other side of the polymer film substrate, and the two ends of the polymer film substrate have a metal aluminum layer structure;

[0031] Evaporated metal aluminum layer in a vacuum of 1 × 10 -3 ~1×10 -5 It is carried out in the vacuum coating system of Pa, and the evaporation rate is 0.2nm / s~2nm / s.

[0032] Evaporated polyimide film layer in a vacuum of 1 × 10 -3 ~1×10 -5 It is carried out in a vacuum coating system of Pa, and the evaporation rate is 0.1nm / s~1nm / s.

[0033] Polyimide film is prepared by ...

Embodiment 1

[0046] The fabrication steps of the flexible substrate include the following:

[0047] Step 1: Provide a polymer film substrate PET film with a thickness of 1mm and clean it;

[0048] Step 2: In a vacuum of 1 x 10 -5 In Pa's vacuum coating system, the first metal aluminum layer is prepared by evaporation on the first surface of the PET film of the polymer film substrate, with a thickness of 50nm and an evaporation rate of 0.5nm / s;

[0049] Step 3: In a vacuum of 1 x 10 -5 In the vacuum coating system of Pa, on the basis of step 2, on the other surface of the PET film of the polymer film substrate, evaporation prepares the second metal aluminum layer, and then the surface evaporation of the second metal aluminum layer prepares the polyimide film layer, successively Alternately repeat the preparation of the second metal aluminum layer and the polyimide film layer, the number of polyimide layers is 3 layers, the number of layers of the second metal aluminum layer is 4 layers, a...

Embodiment 2

[0059] The preparation of this flexible conductive electrode follows the following method:

[0060] Step 1: Provide a polymer film substrate PI film with a thickness of 0.1mm and clean it;

[0061] Step 2: In a vacuum of 1 x 10 -3 In the vacuum coating system of Pa, on one surface of the polymer film substrate PI, the first metal aluminum layer is prepared by evaporation, the thickness is 100nm, and the evaporation rate is 0.2nm / s;

[0062] Step 3: In a vacuum of 1 x 10 -3 In the vacuum coating system of Pa, on the basis of step 2, on the other surface of the polymer film substrate PI film, the second metal aluminum layer is prepared by evaporation, and then the polyimide film is prepared by evaporation on the surface of the second metal aluminum layer Layers, alternately and repeatedly prepare the second metal aluminum layer and the polyimide film layer, the number of polyimide layers is 2 layers, the number of layers of the second metal aluminum layer is 3 layers, and the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com