A kind of preparation method and device of high-quality silicon carbide crystal

A silicon carbide, high-quality technology, applied in chemical instruments and methods, crystal growth, single crystal growth, etc., can solve problems such as excessive carbonization rate, increased crystal stress, corrosion of crucible and insulation layer, etc., to avoid defects or cracks , reduce the risk of cracking, and stabilize the growth rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

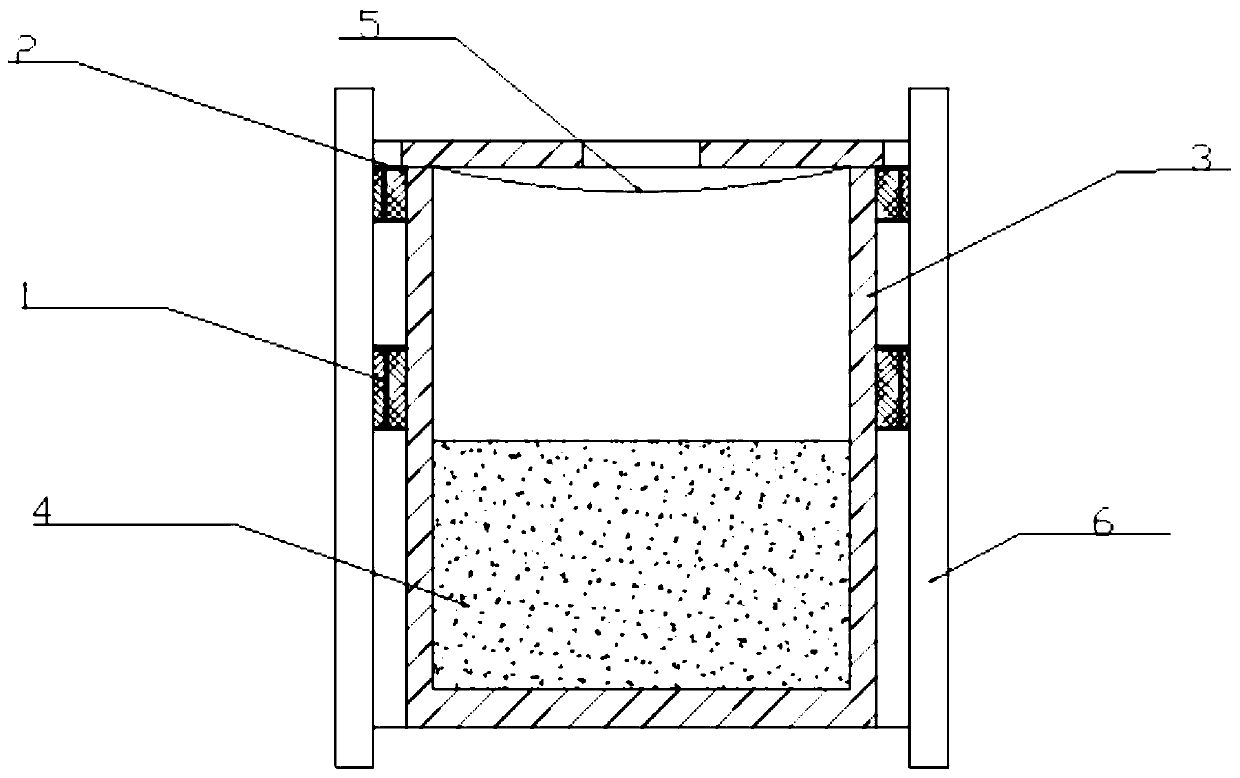

[0035]As an embodiment of the targeted design of the specific thermal field in the present invention: the first collar can reduce the temperature at the place where the seed crystal is placed; the second collar can increase the temperature on the surface of the raw material to form a specific thermal field area and change the temperature inside the crucible. The gas phase transmission path realizes fast and effective thermal field and fluid control.

[0036] Wherein, the projection height of the first collar to the graphite crucible is 25-35mm, preferably 28-32mm; the thickness of the first collar is 4-8mm, preferably 5-7mm. The first collar includes a graphite ring coated with a metal coating, the metal having a higher thermal conductivity than the graphite. Wherein, the thickness of the metal coating is 1-3 mm, preferably 2 mm.

[0037] in such as figure 1 In the shown embodiment, the first collar is a metal-coated graphite ring 1 whose bottom is substantially flat with th...

Embodiment 1

[0054] S1, put 6kg of silicon carbide powder into a graphite crucible, cover the crucible top cover with silicon carbide seed crystals, place a molybdenum-coated graphite ring and a zirconia-coated graphite ring in sequence on the outer wall of the graphite crucible, wherein the molybdenum-coated The layered graphite ring is placed on the surface of the silicon carbide powder, the zirconia-coated graphite ring is placed on the surface of the silicon carbide seed crystal, and then the insulation layer is wrapped, and the crystal growth furnace is sealed;

[0055] S2, evacuate the crystal growth furnace, pass helium gas protection for 5 hours, first raise the pressure to 10mbar at a rate of 2mbar / h, and then raise the temperature to 2400°C within 15h at a rate of 2.5°C / min;

[0056] S3, under the conditions of 10mbar and 2400°C, crystal growth at constant temperature and pressure, and the growth time is 200h;

[0057] S4, the temperature is lowered and cooled for 20 hours, and t...

Embodiment 2

[0059] S1, put 6kg of silicon carbide powder into the graphite crucible, cover the crucible top cover with silicon carbide seed crystals, and place a tantalum-coated graphite ring and a zirconia-coated graphite ring in sequence on the outer wall of the graphite crucible, wherein the tantalum-coated The layered graphite ring is placed on the surface of the silicon carbide powder, the zirconia-coated graphite ring is placed on the surface of the silicon carbide seed crystal, and then the insulation layer is wrapped, and the crystal growth furnace is sealed;

[0060] S2, evacuate the crystal growth furnace, pass in neon gas for protection for 7 hours, first increase the pressure to 12mbar at a rate of 1mbar / h, and then increase the temperature to 2350°C within 14h at a rate of 3°C / min;

[0061] S3, under the conditions of 12mbar and 2350°C, crystal growth at constant temperature and pressure, and the growth time is 210h;

[0062] S4, the temperature was lowered and cooled for 18 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com