Textile dryer

A technology of a dryer and a drying box, applied in the textile field, can solve the problems of shortening the service life of heating components, affecting the drying efficiency of cloth, reducing the energy efficiency of the dryer, etc., and achieving the effect of being convenient for recycling and reuse.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

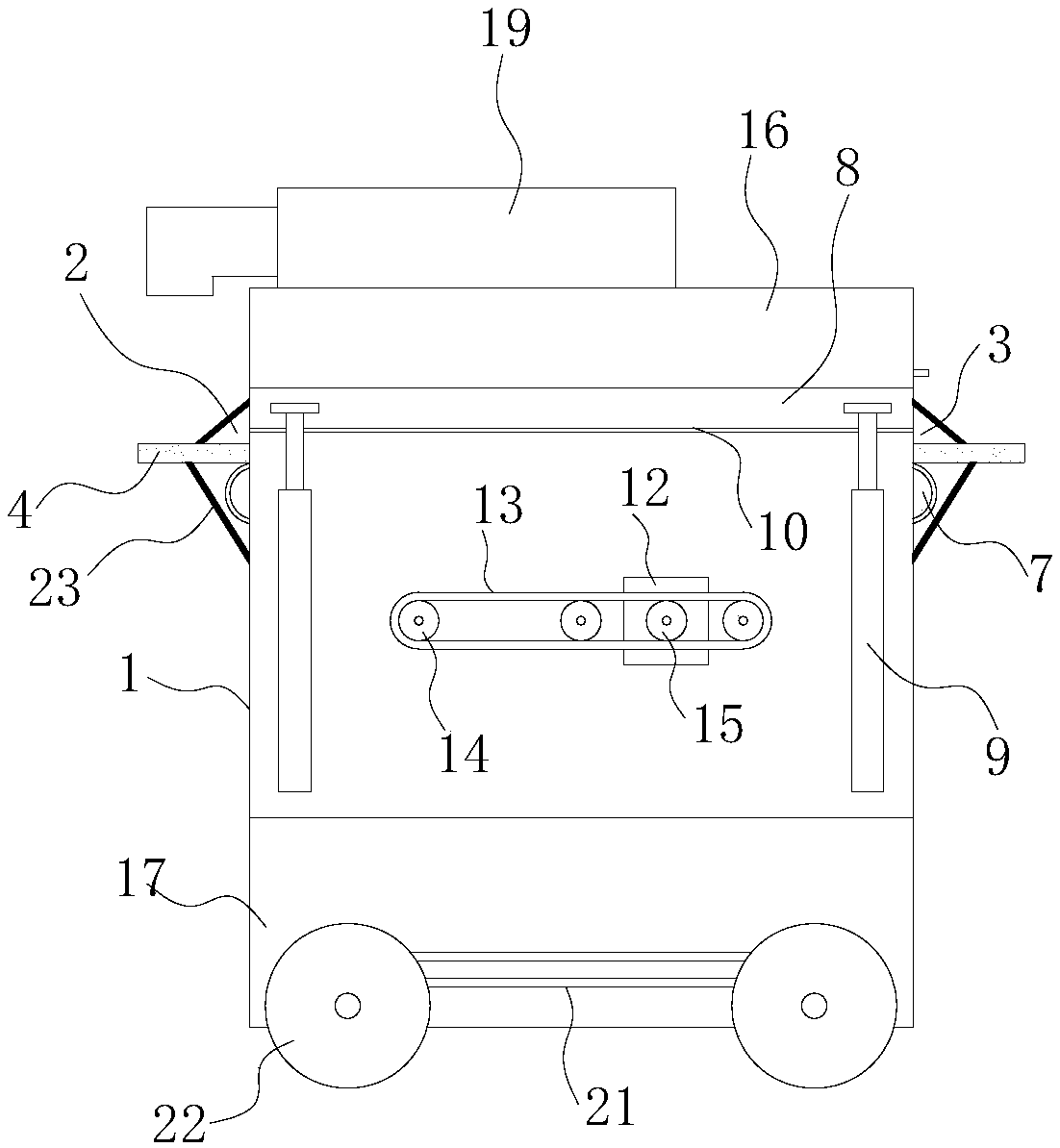

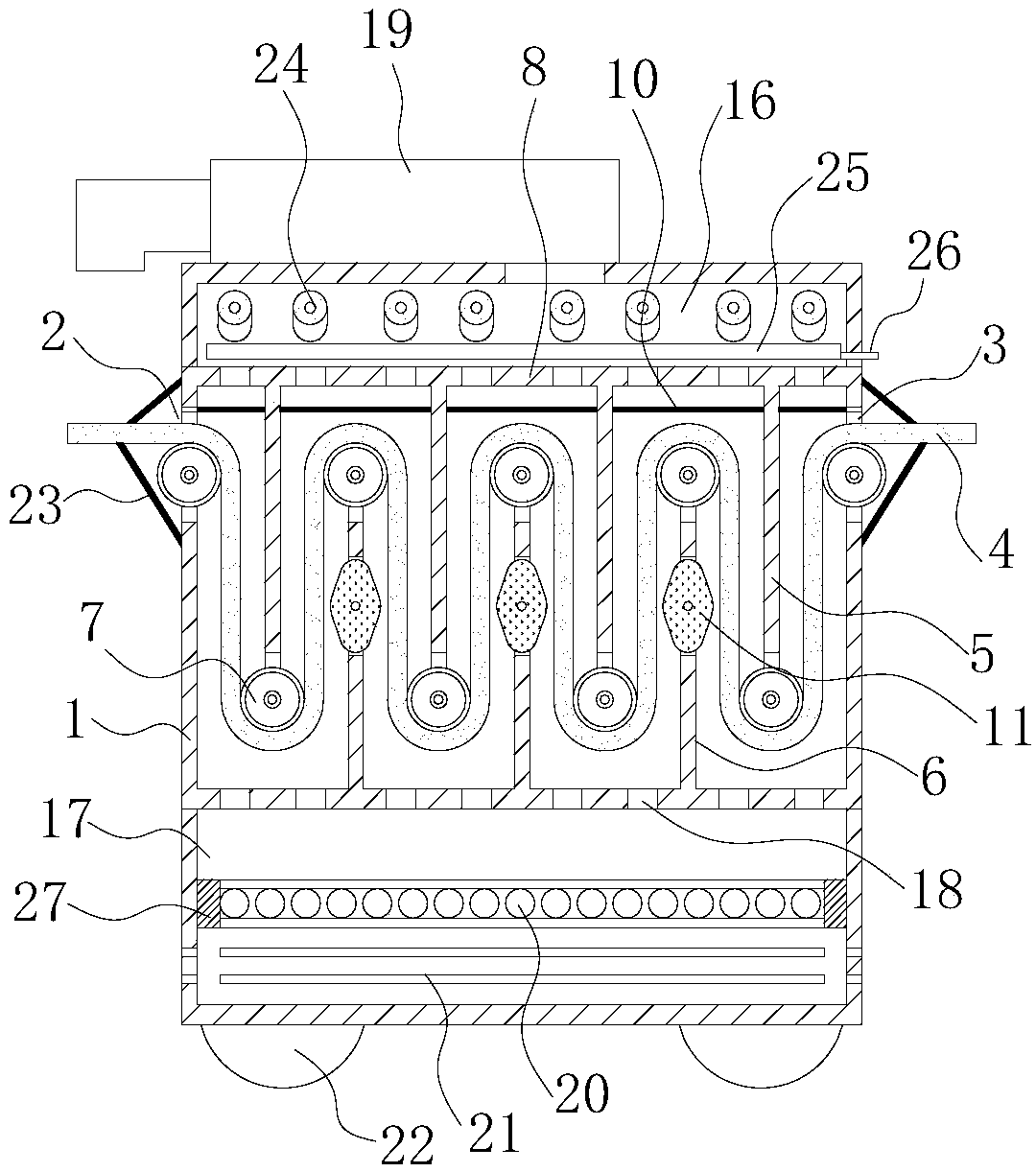

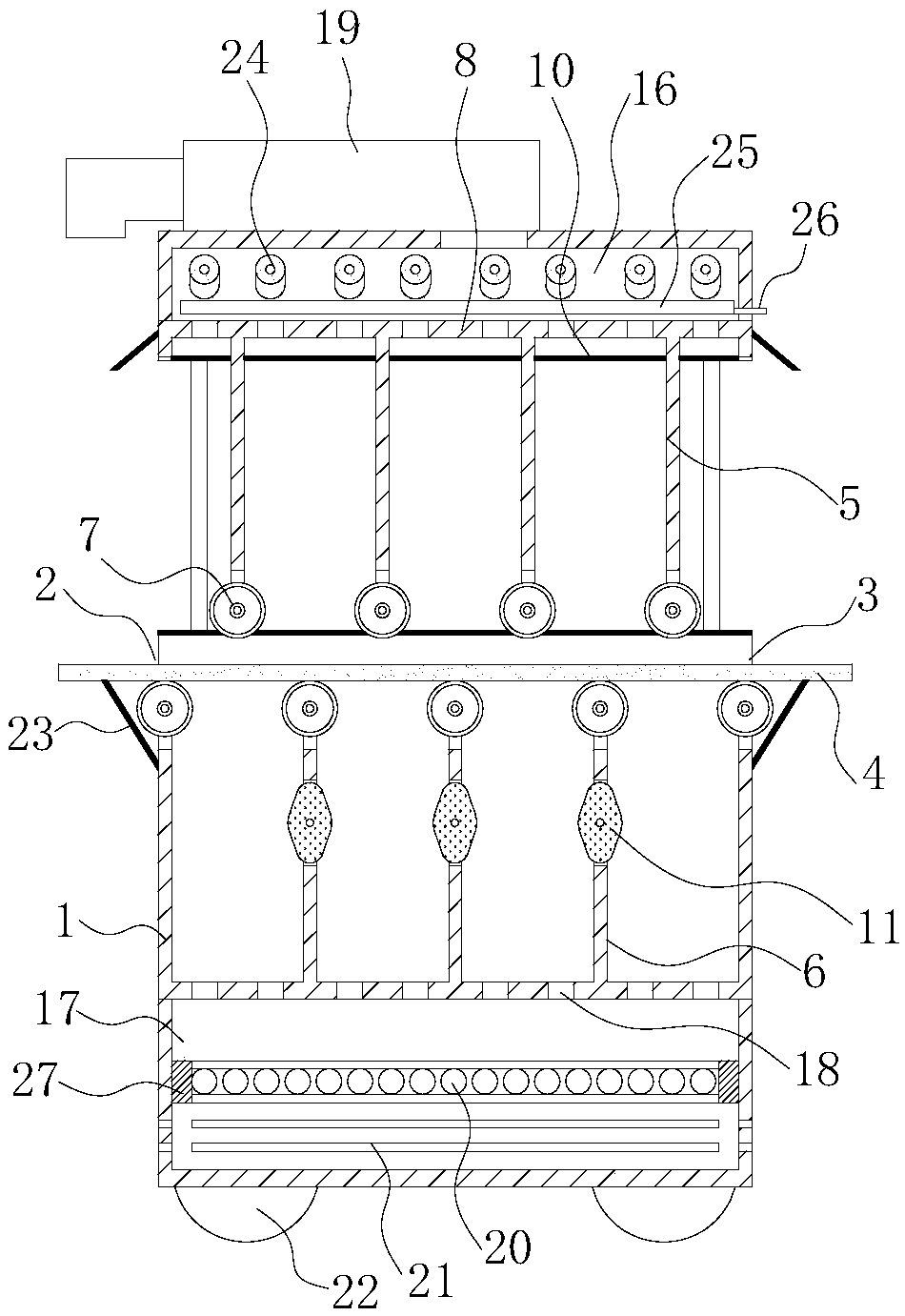

[0025] Such as Figure 1-5 A textile dryer shown includes a drying box 1 and a hot air device. The left side of the drying box 1 is provided with a cloth inlet 2, and the right side is provided with a cloth outlet 3, and the cloth inlet 2 and the cloth outlet 3 are used for cloth 4 to enter and exit the drying box 1, so the cloth inlet 2 and the outlet The length of cloth mouth 3 should be suitable with the width of cloth 4. The hot air device is used to send hot air for heating the cloth 4 into the drying box 1, and the cloth 4 is dried by the hot air while passing through the drying box 1 through the cloth inlet 2 and the cloth outlet 3. That is to say, the function of the hot air device is to generate hot air, and make the hot air flow in the drying box 1 to heat and dry the cloth 4 .

[0026] Compared with the traditional dryer, one of the main differences of the present invention is: as Figure 4 As shown, multiple vertical upper partitions 5 and lower partitions 6 are...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com