Evaluation method for corrosion state of in-service power transmission line rod tower and metal framework

A transmission line, corrosion state technology, applied in the direction of weather resistance/light resistance/corrosion resistance, measuring devices, instruments, etc., can solve the problems of detection, differential treatment and high requirements without considering the impedance of the coating layer, so as to reduce the risk of power grid operation, Evaluate accurate results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] In order to better understand the present invention, the present invention will be further described below in conjunction with accompanying drawing and specific embodiment:

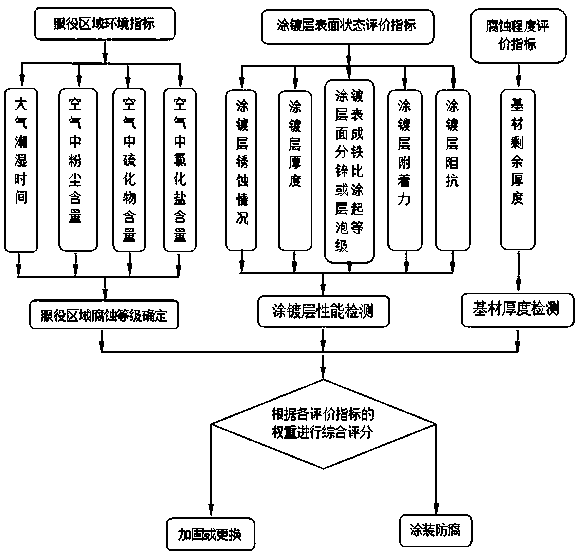

[0019] Such as figure 1 As shown, a method for evaluating the corrosion state of towers and metal structures of in-service transmission lines includes the following steps:

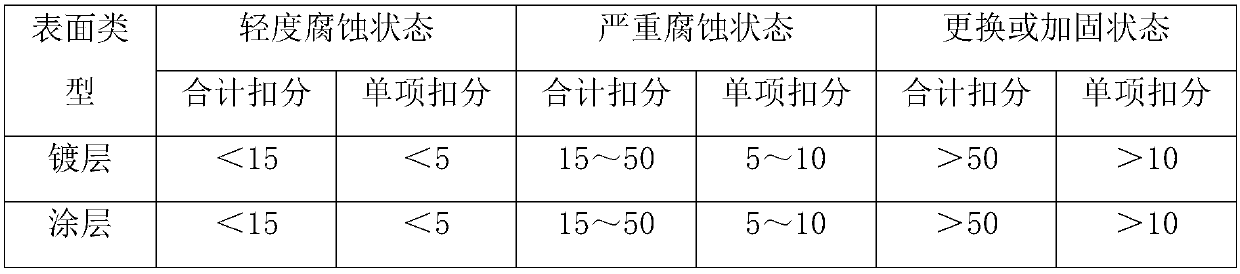

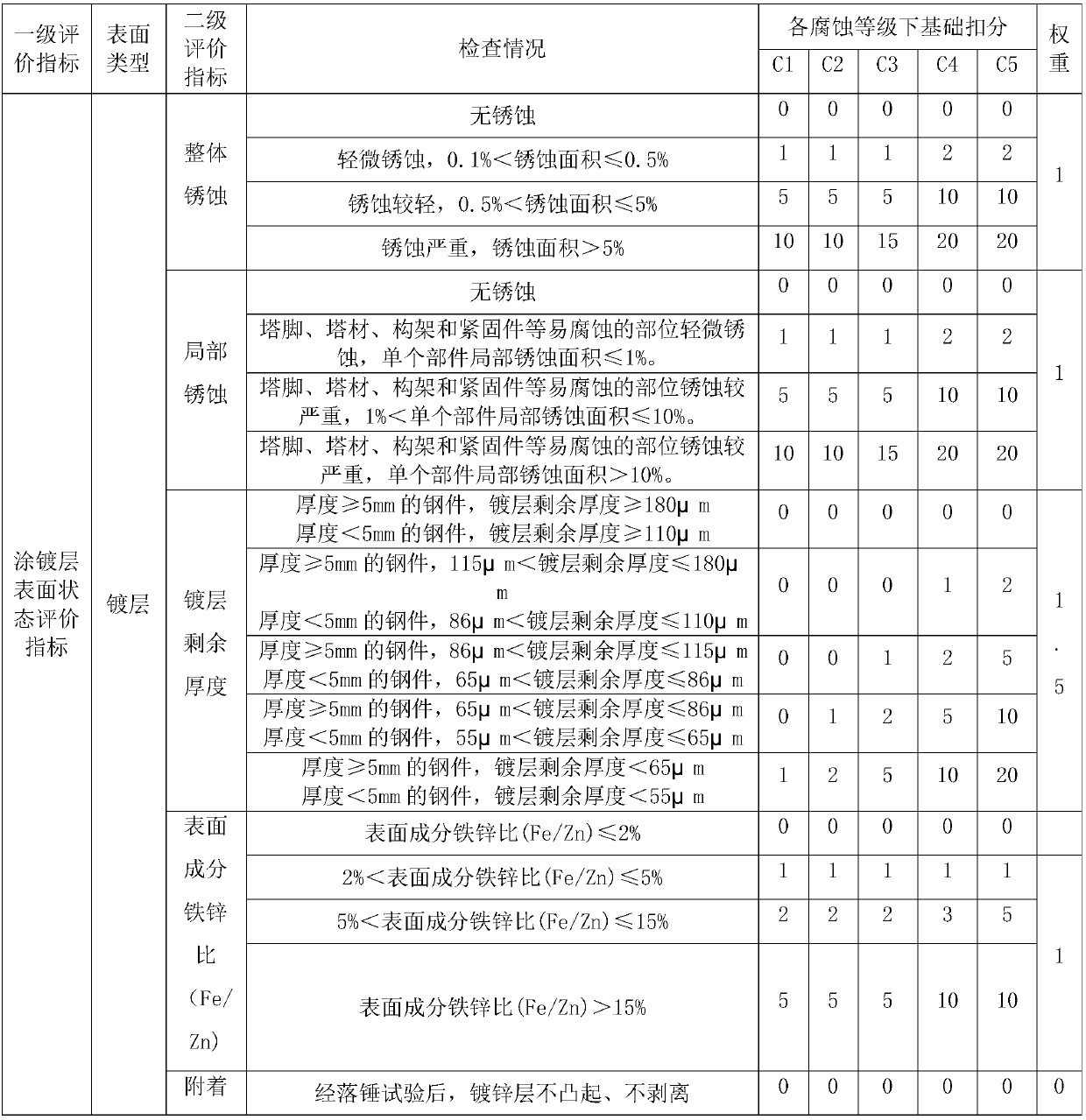

[0020] (1) Evaluation indicators for detecting the corrosion status of in-service transmission line towers and metal structures; the evaluation indicators include three first-level evaluation indicators, specifically: service area environmental indicators, coating surface state evaluation indicators, and corrosion degree evaluation indicators; service areas Environmental indicators include 4 secondary indicators, specifically: atmospheric humidity time, dust content in the air, sulfur compound content in the air, and chloride salt content in the air; the coating surface state evaluation indicators include 5 secondary indicators...

PUM

| Property | Measurement | Unit |

|---|---|---|

| impedance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com