Automatic assembling and pressing mechanism for watch shell

A technology of automatic assembly and pressing mechanism, which is applied in clocks, clocks, repair tools, etc., can solve the problems of low efficiency of manual assembly, affecting the timing accuracy of clock movements, and high production costs of clock movements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

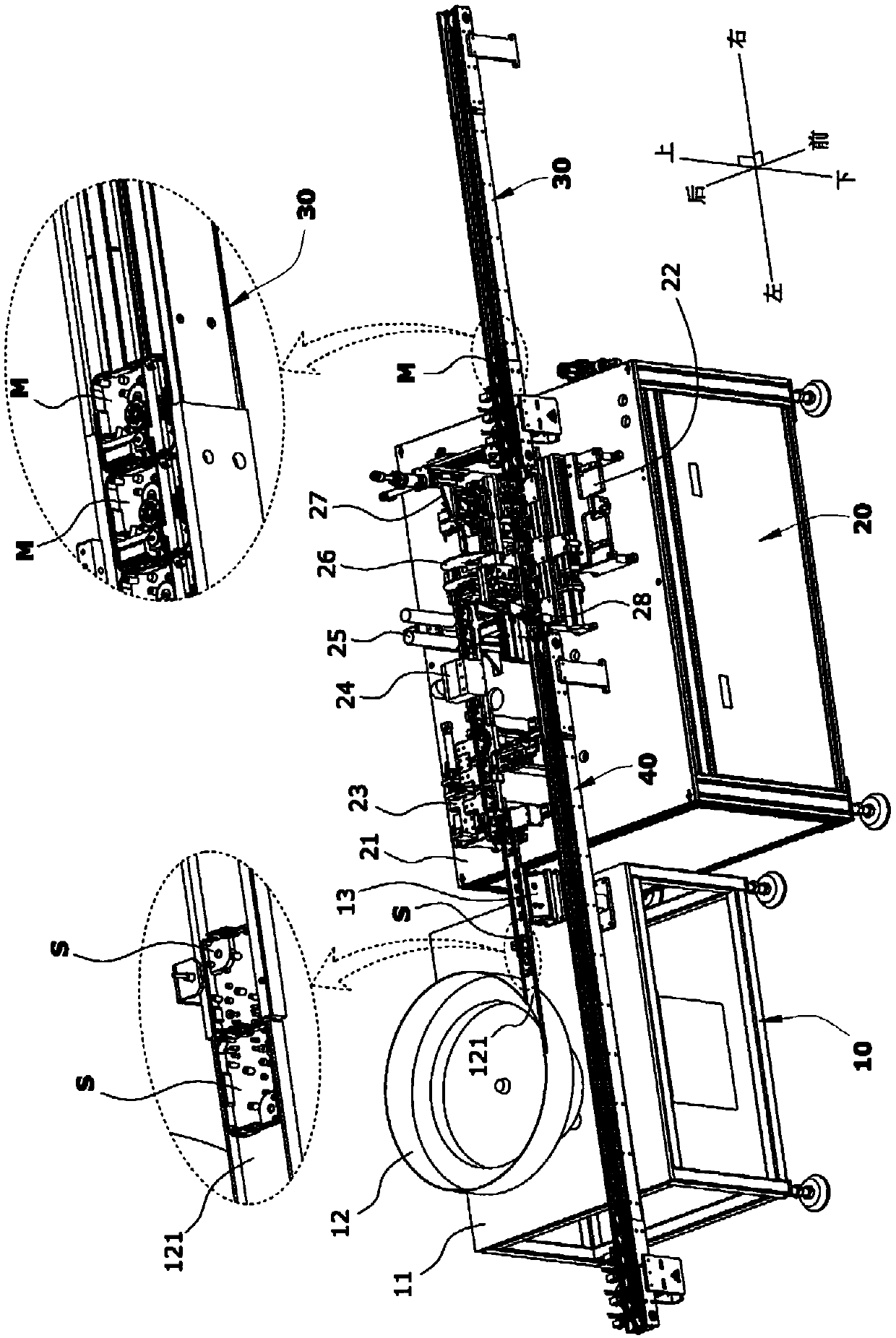

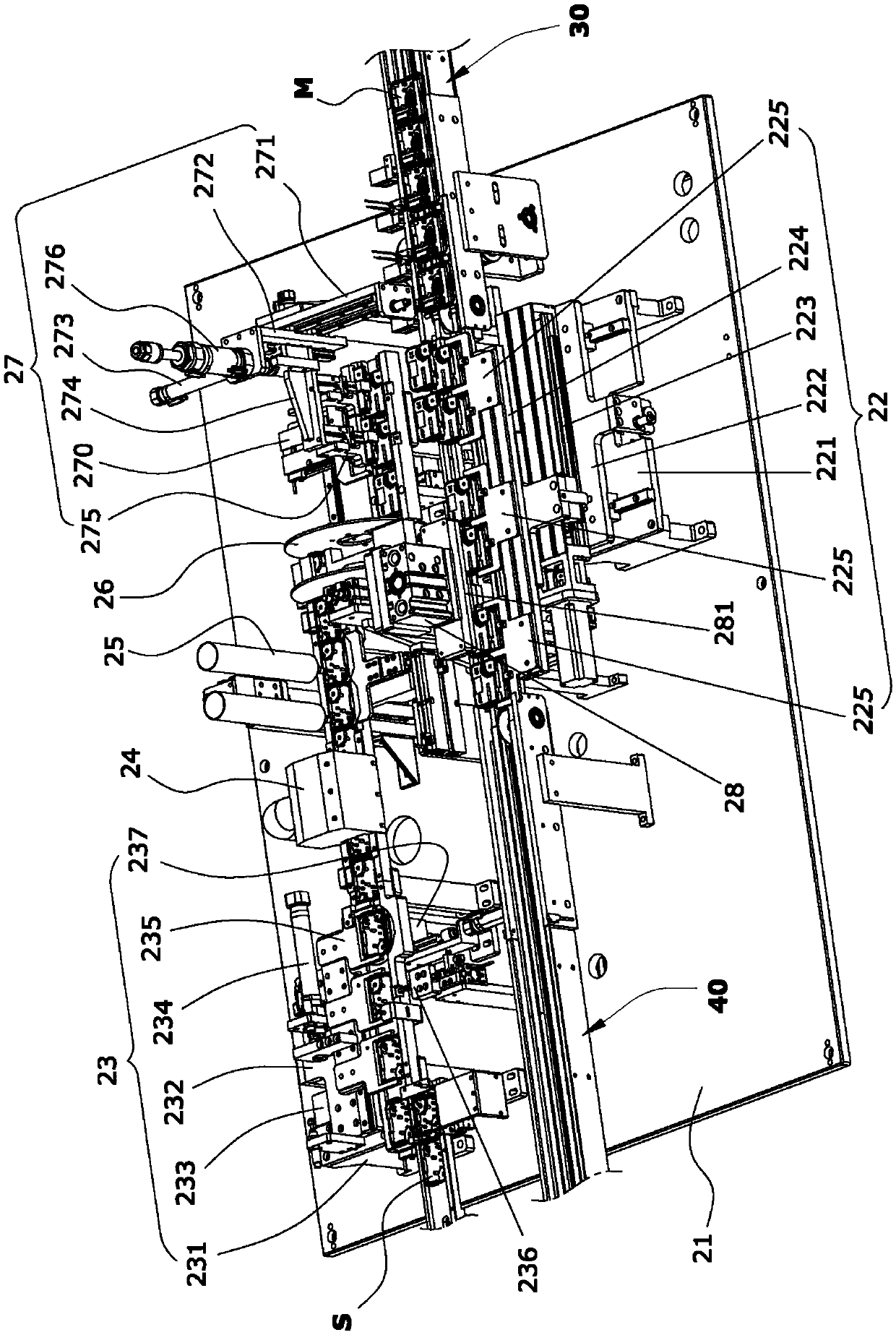

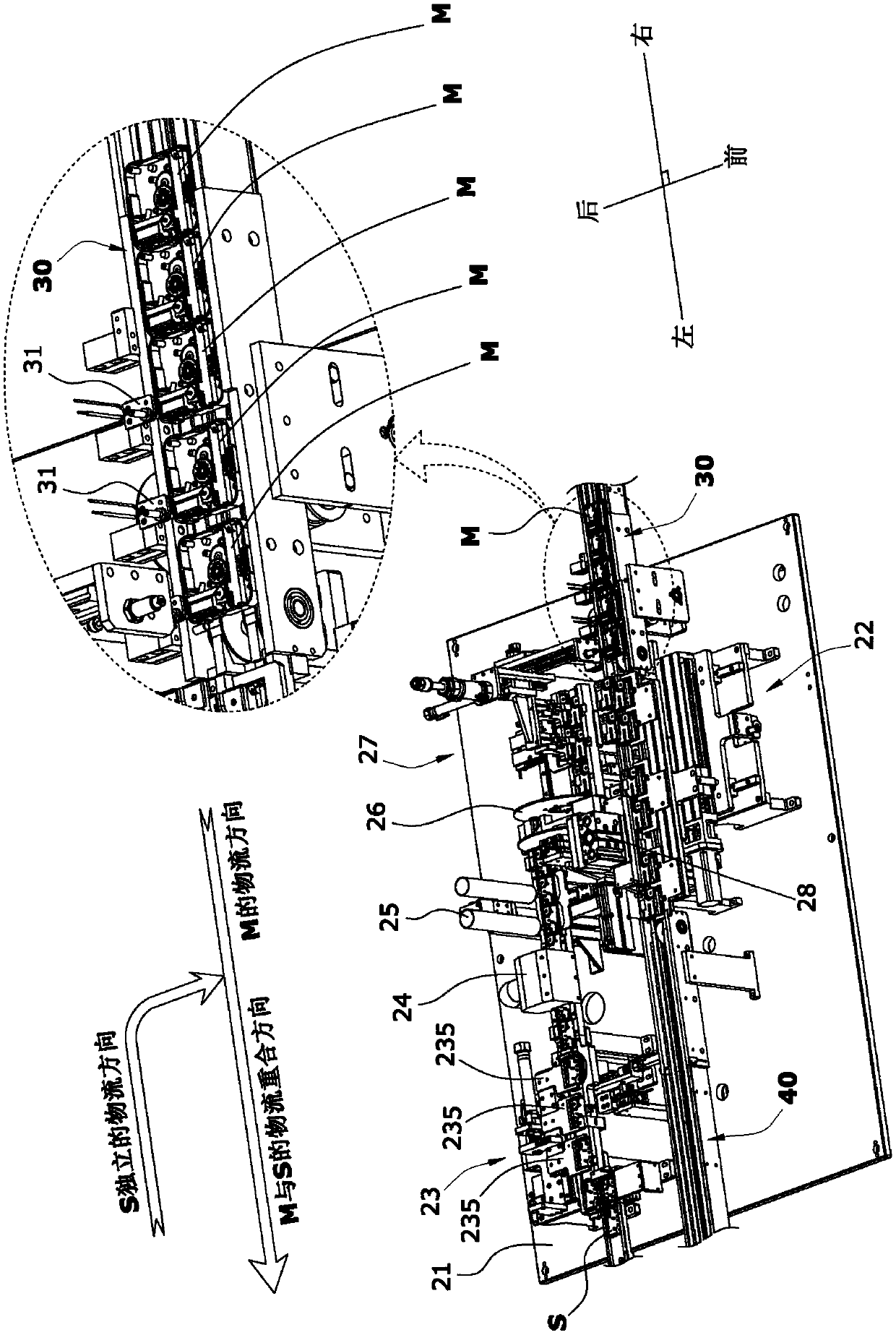

[0027] Such as Figure 1 ~ Figure 3 The shown automatic assembly and pressing mechanism of a watch case includes a feeder 10 for supplying the case cover S of the watch and a distributor 30 for conveying the bottom case M of the watch, the feeder 10 and the distributor An assembly machine 20 is installed between the mechanism 30, which can automatically fit and crimp the incoming materials of the shell cover S and the bottom shell (M). The assembly machine 20 includes a table 21; Installed on the top in order: a shell handling device 23 that can align and transport the shell cover S supplied by the feeder 10 with the back facing up, a vacuum cleaner 24 that can remove dust from the shell cover S, and two shell covers that can be aligned. An oil spotter 25 for S pointing oil, a flipper 26 that can turn the shell cover S to the backside down, and a shell...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com