Croissant negative pressure initiation roll-up device

A croissant and negative pressure technology, which is applied in the direction of rolling dough sheet machines, can solve problems such as poor rolling effect, achieve the effects of reducing labor costs, enhancing rolling effect, and improving automatic production capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

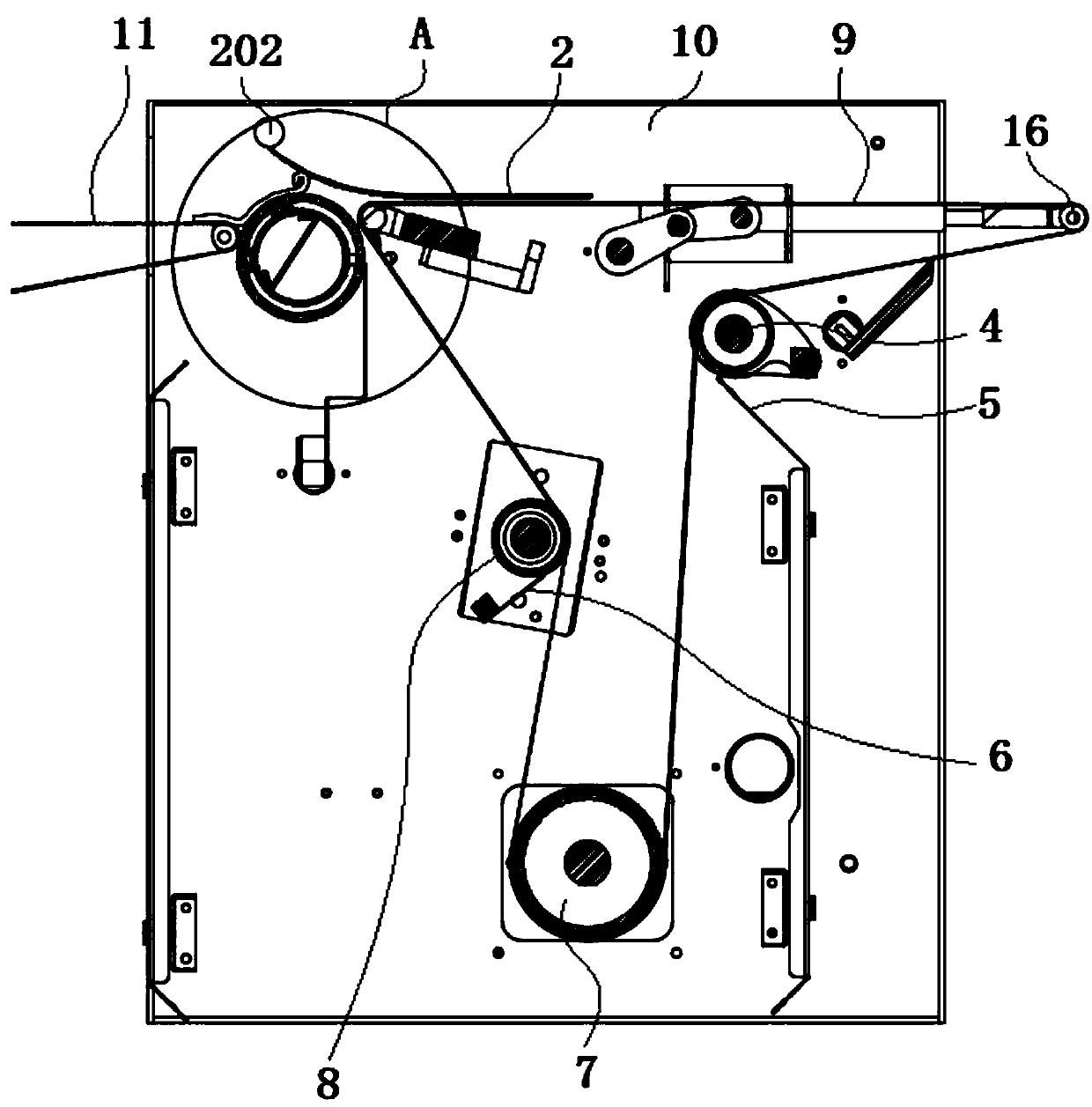

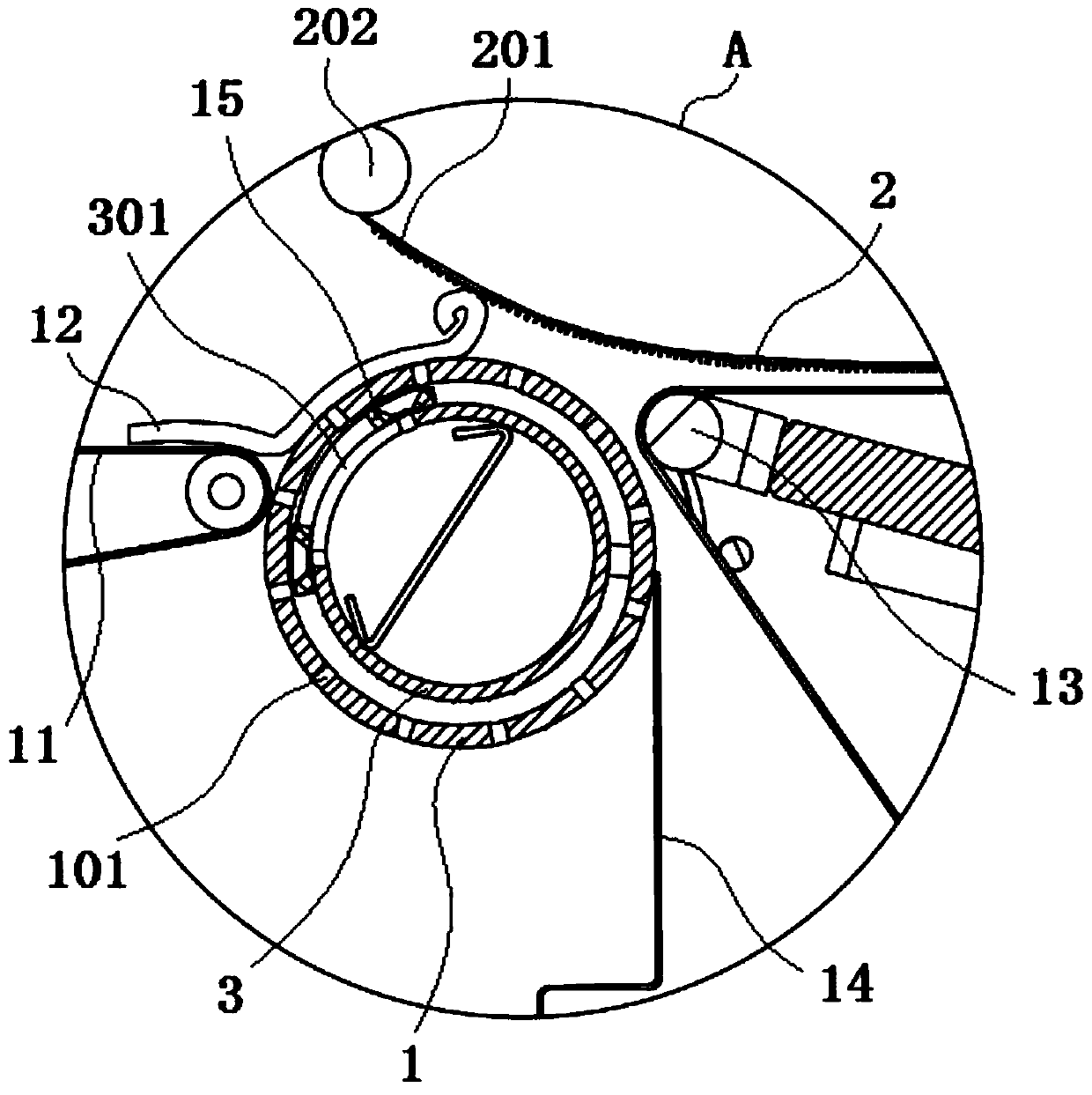

[0022] Such as figure 1 , figure 2 As shown, the present invention is a negative pressure rolling device for croissants, comprising a box body 10, the top of the box body 10 is equipped with a negative pressure exhaust duct 3, and the negative pressure exhaust duct 3 is provided with a tuyere 301 along the length direction. The outer wall of the negative pressure exhaust pipe 3 rotates with a rotating porous roller 1, and the cylindrical surface of the rotating porous roller 1 is uniformly provided with ventilation holes 101; one side of the rotating porous roller 1 is equipped with a feeding belt 11, and the negative pressure exhaust pipe 1 A conveyor belt 9 is installed on one side, and a fixed rod 202 is installed on the top of the rotating perforated roller 1, and an end of the embossed belt 2 is installed on the fixed rod 202; on the surface of the embossed belt 2, there are embossed lines 201 arrayed along the width direction; The dough body 12 is adsorbed by the rotat...

specific Embodiment 2

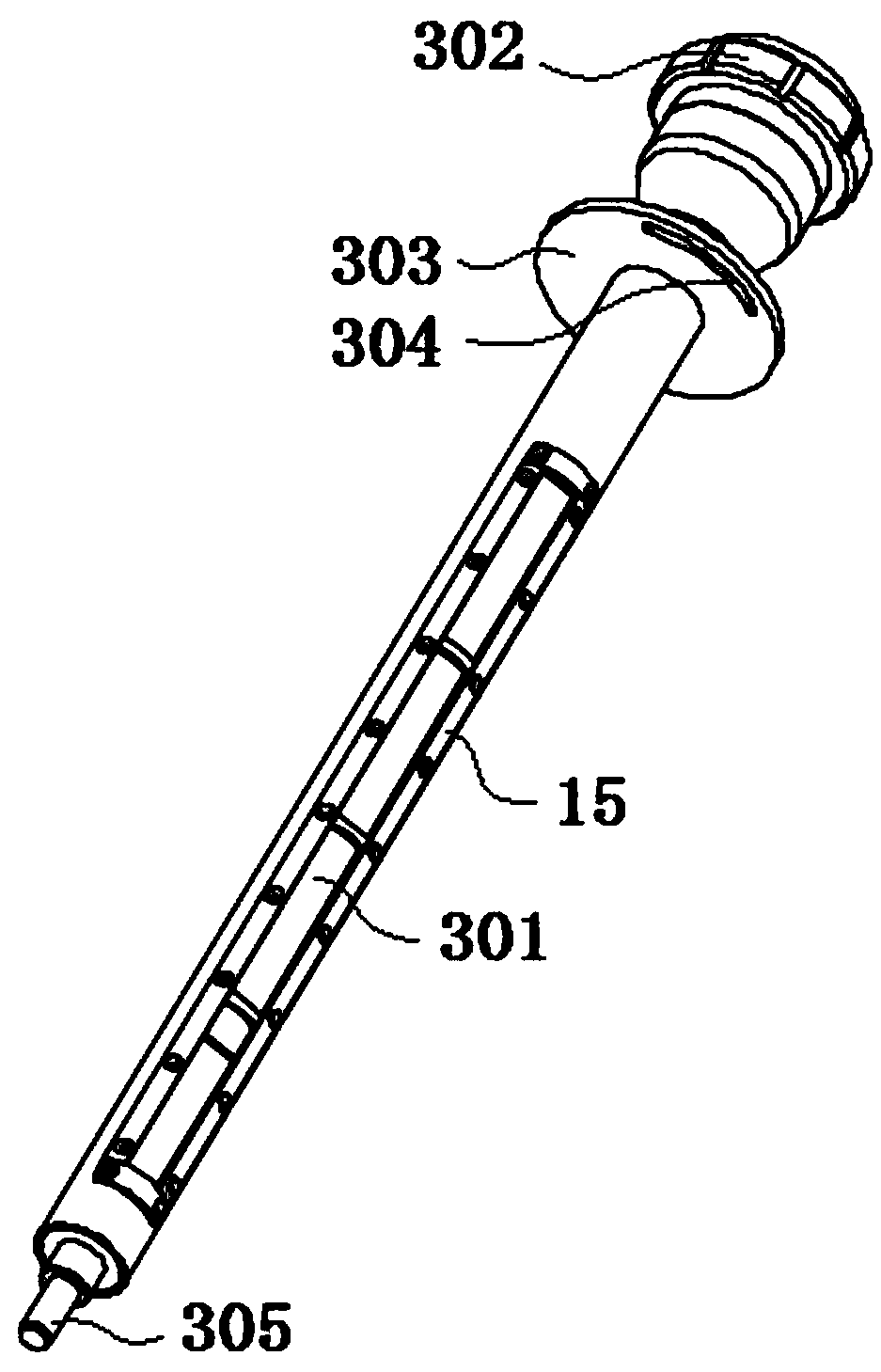

[0027] Such as image 3 As shown, one end of the negative pressure exhaust pipe 3 is provided with a shaft end 305, and the other end of the negative pressure exhaust pipe 3 is provided with a ventilation end 306 and a flange 303 in turn, the ventilation end 306 is provided with a vent 302, and the flange 303 is provided with a ventilation port 302. There is a waist hole 304; such as Figure 4 As shown, a housing 19 is installed on the box body 10, and a bearing seat 18 is installed in the housing 19, and a set of bearings 17 arranged on the tuyere regulating pipe 3 peripheral sides are installed in the bearing seat 18; There is a fixed rod 20, the fixed rod 20 is evenly equipped with embossed strips 2, the embossed belt 2 is equipped with a counterweight 203; the shaft end 305 is equipped with a power shaft 22, and the power shaft 22 is equipped with a power sprocket twenty one.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com