Handrail automatic length measuring and cutting production line

A handrail belt and production line technology, which is applied in the direction of winding strips, sending objects, thin material processing, etc., can solve the problems of messy and disorderly workshops, handrail belt damage, and poor length measurement accuracy, so as to improve automatic production capacity and save energy. Space and manpower, and the effect of improving productivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

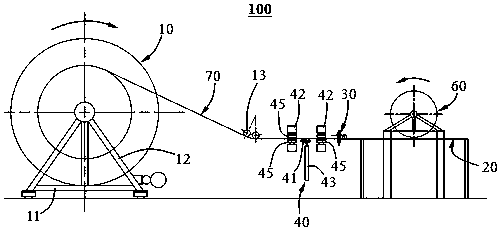

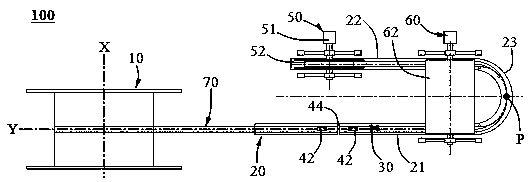

[0015] see figure 1 As shown, the present invention provides a handrail automatic length measurement and cutting production line 100, comprising: a handrail material barrel 10, a track 20, a length measuring device 30 and a cutting device 40 installed on the track 20, and a first winder 50 And the second winder 60. The handrail material cylinder 10 is used for winding the handrail 70, which is used as a supply device for the handrail, and conveys the handrail to the first winder 50 and the second winder 60 through the track 20, and finally the handrail is passed by The first winder 50 and the second winder 60 complete the winding of the cut handrail.

[0016] The handrail material cylinder 10 is located at one end of the track 20, and is used to send the handrail belt 70 into the track 20, and the handrail material cylinder 10 can move along its central axis direction to meet the direction of the handrail belt. Always align with the entrance of the track 20, the central axis...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com