Waste gas flow guiding device of surface treatment groove

A technology of surface treatment and diversion device, applied in the direction of cells, electrolysis process, electrolysis components, etc., can solve the problems of inability to lift the gas collecting hood, damage the lifting crane, reduce production efficiency, etc., to avoid corrosion and damage to the crane, guarantee The effect of improving physical health and improving the drainage effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

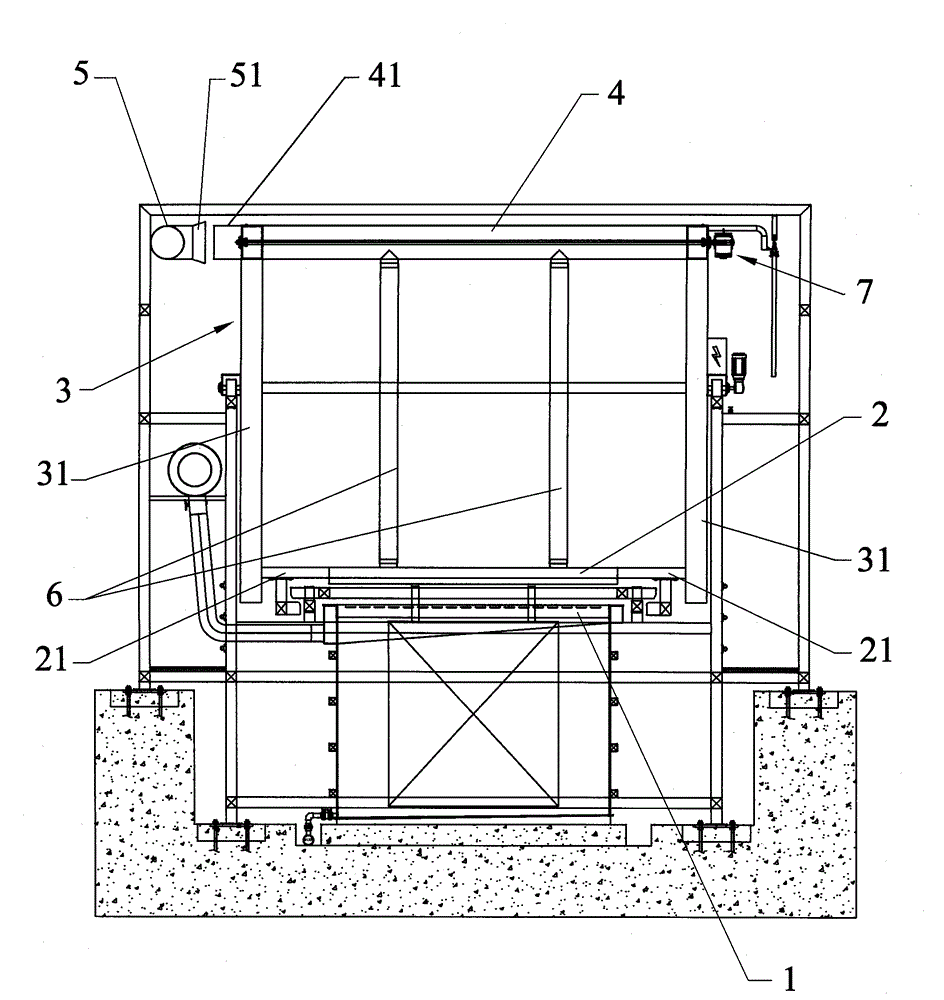

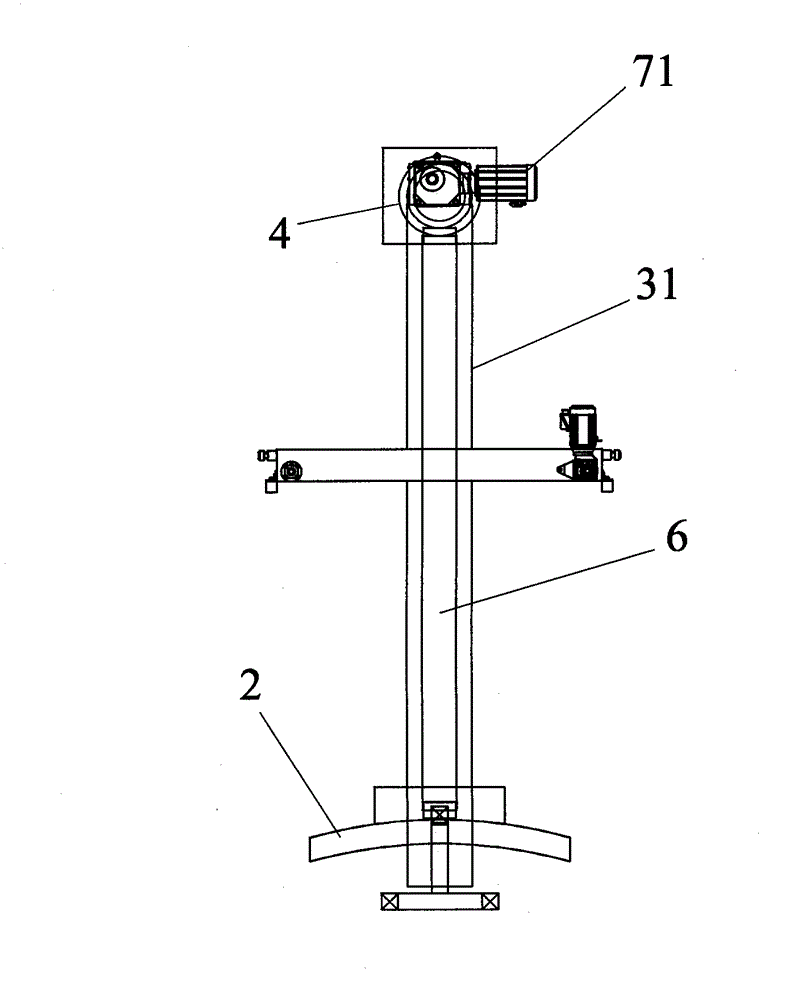

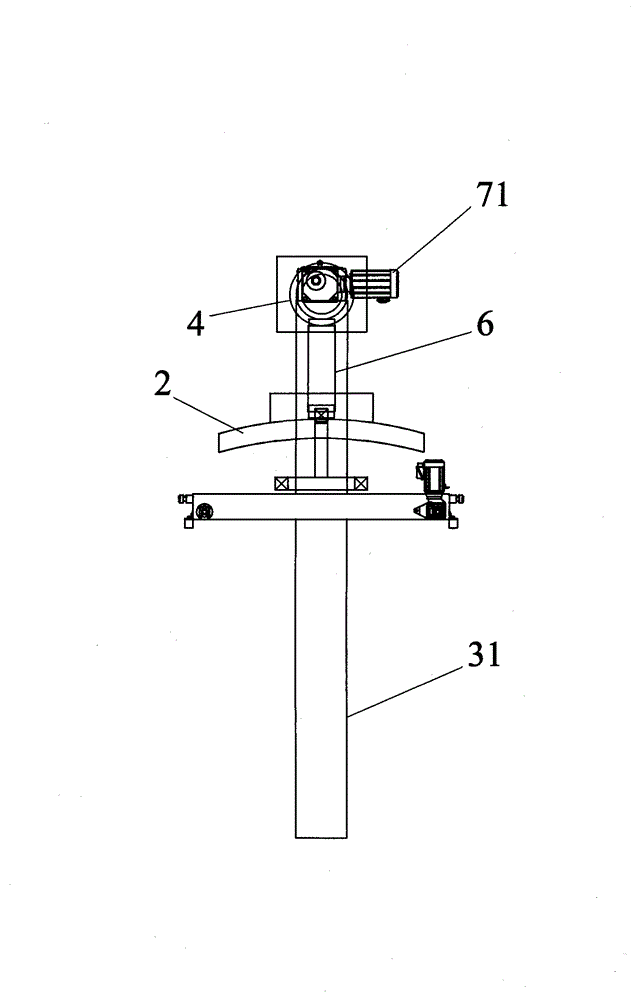

[0024] Below in conjunction with accompanying drawing, the present invention will be further described:

[0025] Such as Figure 1 to Figure 4 As shown, the waste gas guide device for surface treatment tanks of the present invention has a structure as follows: it includes several coating tanks 1, a crane that is movably positioned above the coating tanks 1, a main exhaust pipe 5 connected with an exhaust fan, and a PLC Control system, flow guide cover 2, telescopic throat pipe 6, frame body 3 installed in the crane, exhaust branch pipe 4 installed in frame body 3, and cover body lifting drive mechanism 7 for driving the flow guide cover 2 to move up and down The shroud 2 is located below the exhaust branch pipe 4 and can be moved with the crane above the plating tank 1, the telescopic throat pipe 6 is connected between the shroud 2 and the exhaust branch pipe 4, and the cover lifting drive mechanism 7 is driven to connect the shroud 2; the position of the main exhaust duct 5 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com