Multi-layer film and preparation method thereof

A multi-layer film and unit layer technology, applied in the field of materials, can solve problems such as difficulty in removing straps and reduced comfort, and achieve the effect of optimizing toughness and hardness and increasing taste comfort

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0048] Example 1 Three-layer diaphragm TPU-PETG-TPU

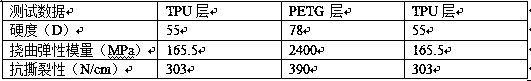

[0049] S1: Dry the raw materials of the three unit layers, wherein the drying temperature is 98 ° C, and the drying time is 4 hours; the parameter characteristics of the raw materials are shown in the following table:

[0050]

[0051] S2: Add each unit layer raw material after the above drying into a single / twin-screw extrusion system through a separate passage, and pass through a feeding section, a melting section, a homogenizing section and an extrusion section, and the screw speed is 70 rpm; Die head width is 200mm, and die head temperature is 140 ℃; Obtain rough multi-layer sheet; Wherein, the temperature of feeding section is 190 ℃; The temperature of melting section is 210 ℃; The homogenization temperature of the unit layers on both sides is 230°C.

[0052] S3: The extruded crude sheet is rolled by three rollers, the temperature of the upper roller is 80°C, the temperature of the middle roller is 70°C, and the te...

Embodiment 2

[0054] Example 2 Three-layer membrane PETG-TPU-PETG

[0055] Embodiment 2 is similar in structure and preparation method to Embodiment 1, the difference is that the raw materials of each unit layer are different, and the technical parameters involved in the preparation method are different, specifically:

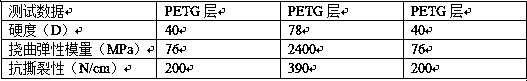

[0056] The parameters of each unit layer are as follows:

[0057]

[0058] The technical parameters involved in the preparation method are as follows:

[0059] S1: Among them, the drying temperature is 130°C, and the drying time is 3 hours;

[0060] S2: Among them, the screw speed is 5 rpm; the width of the die head is 160mm, the temperature of the die head is 200°C; the temperature of the feeding section is 205°C; the temperature of the melting section is 250°C; the homogenization temperature of the middle unit layer is 270°C °C, and the homogenization temperature of the unit layers on both sides is 250 °C.

[0061] S3: Among them, the temperature of the three floatin...

Embodiment 3

[0063] Example 3 Three-layer film PETG-PETG-PETG

[0064] Embodiment 3 is similar in structure and preparation method to Embodiment 1, the difference is that the raw materials of each unit layer are different, and the technical parameters involved in the preparation method are different, specifically:

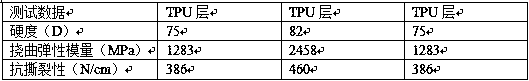

[0065] The parameters of each unit layer are as follows:

[0066]

[0067] The technical parameters involved in the preparation method are as follows:

[0068] S1: Among them, the drying temperature is 90°C, and the drying time is 6 hours;

[0069] S2: Among them, the screw speed is 100 rpm; the die head width is 1200mm, the die head temperature is 180°C; the temperature of the feeding section is 180°C; the temperature of the melting section is 260°C; the homogenization temperature of the middle unit layer is 260°C °C, and the homogenization temperature of the unit layers on both sides is 240 °C.

[0070] S3: Among them, the temperature of the three floating rollers is 60...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tear resistance | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Tear resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com