Novel technology for flocculation, pressure filtration and dehydration of flotation clean coal

A technology of filter press dehydration and new process, which is applied in filtration separation, selective deposition method, solid separation and other directions, can solve the problems of slow filter press speed, equipment loss, increase filter press load, and increase filter pressure pressure, etc. Filtering efficiency, reduced fine particle loss, reduced loss effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

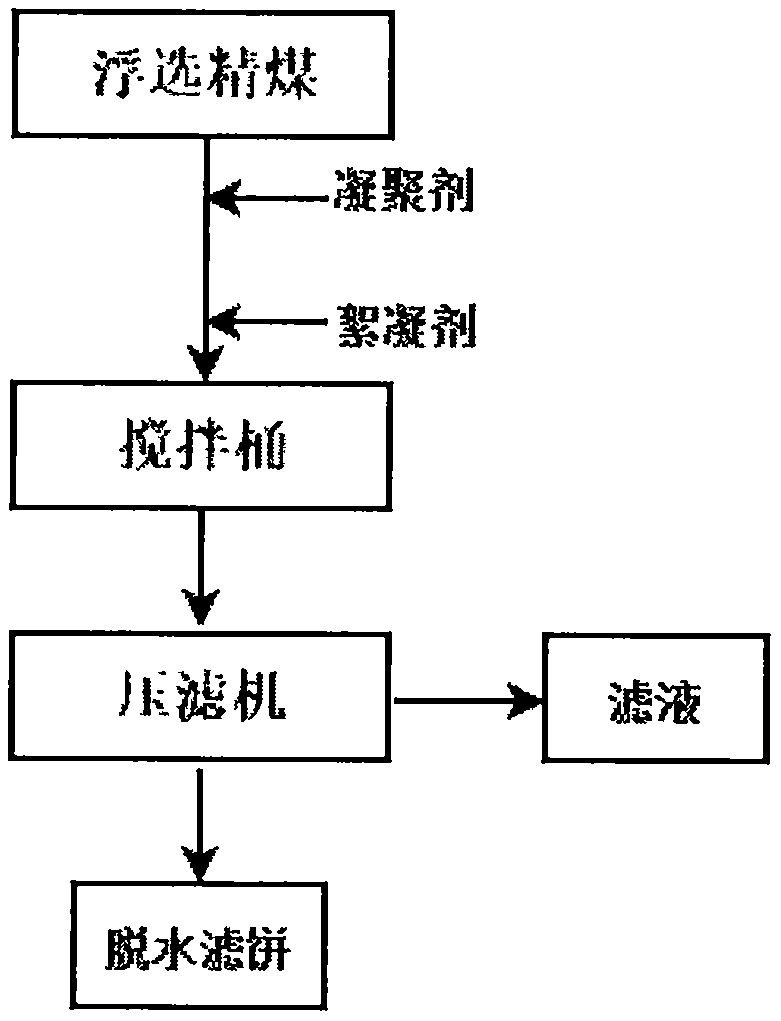

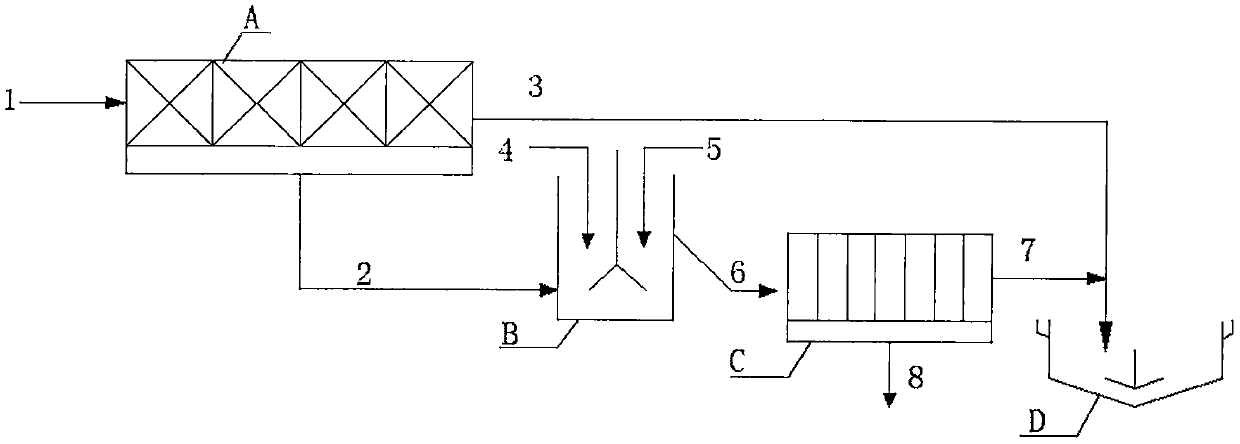

Method used

Image

Examples

example 1

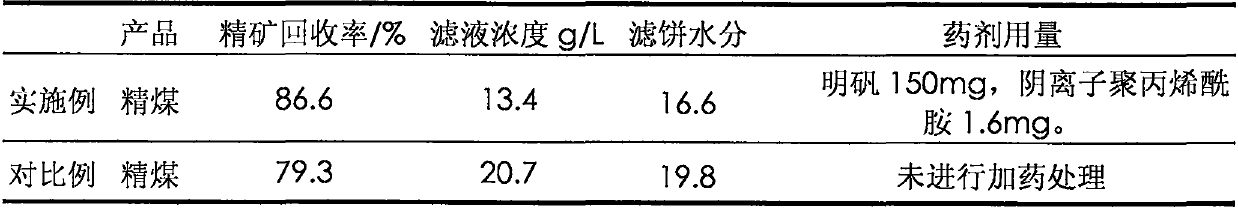

[0024] Example 1: This process carried out a filter press dehydration test on the flotation clean coal of Yuwu Coal Preparation Plant. If this process was not used to process the filter press feed, the concentration of the filtrate obtained after the press filter was 20.7g / L, and the moisture content of the filter cake was 18. %-20%; after using this process to process the filter press feed, the filtrate concentration is 13.4g / L after press filter dehydration, and the filter cake moisture is 16.6%. The relevant test results are shown in Table 1.

[0025] Table 1 Comparison test results of flotation clean coal pressure filtration dehydration in Yuwu Coal Preparation Plant

[0026]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com