Auxiliary clamping device of metallographic grinding and polishing machine

A clamping device, grinding and polishing machine technology, applied in the direction of grinding/polishing equipment, grinding machines, metal processing equipment, etc., can solve the problems of manual processing, time-consuming and labor-intensive grinding and polishing, etc., to achieve high grinding and polishing accuracy, Time saving, time saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

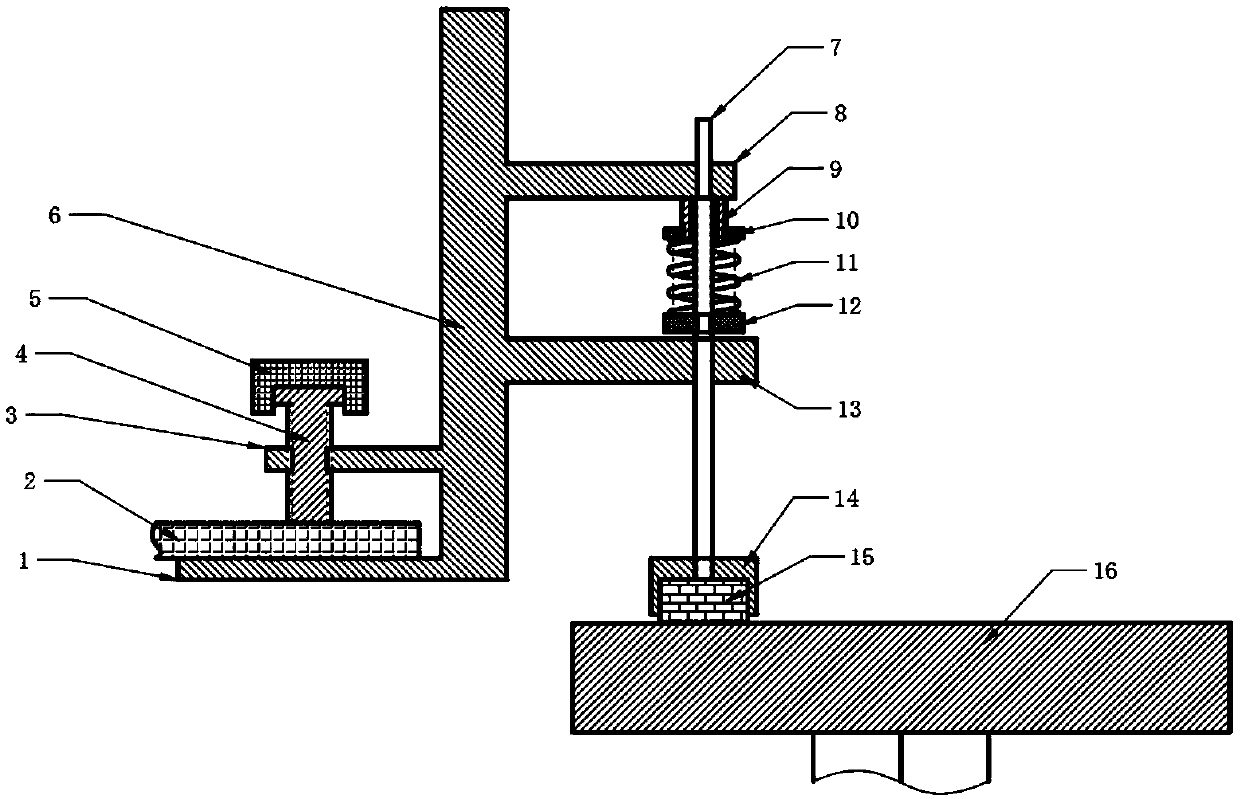

[0021] Below in conjunction with accompanying drawing, the patent of the present invention is further described.

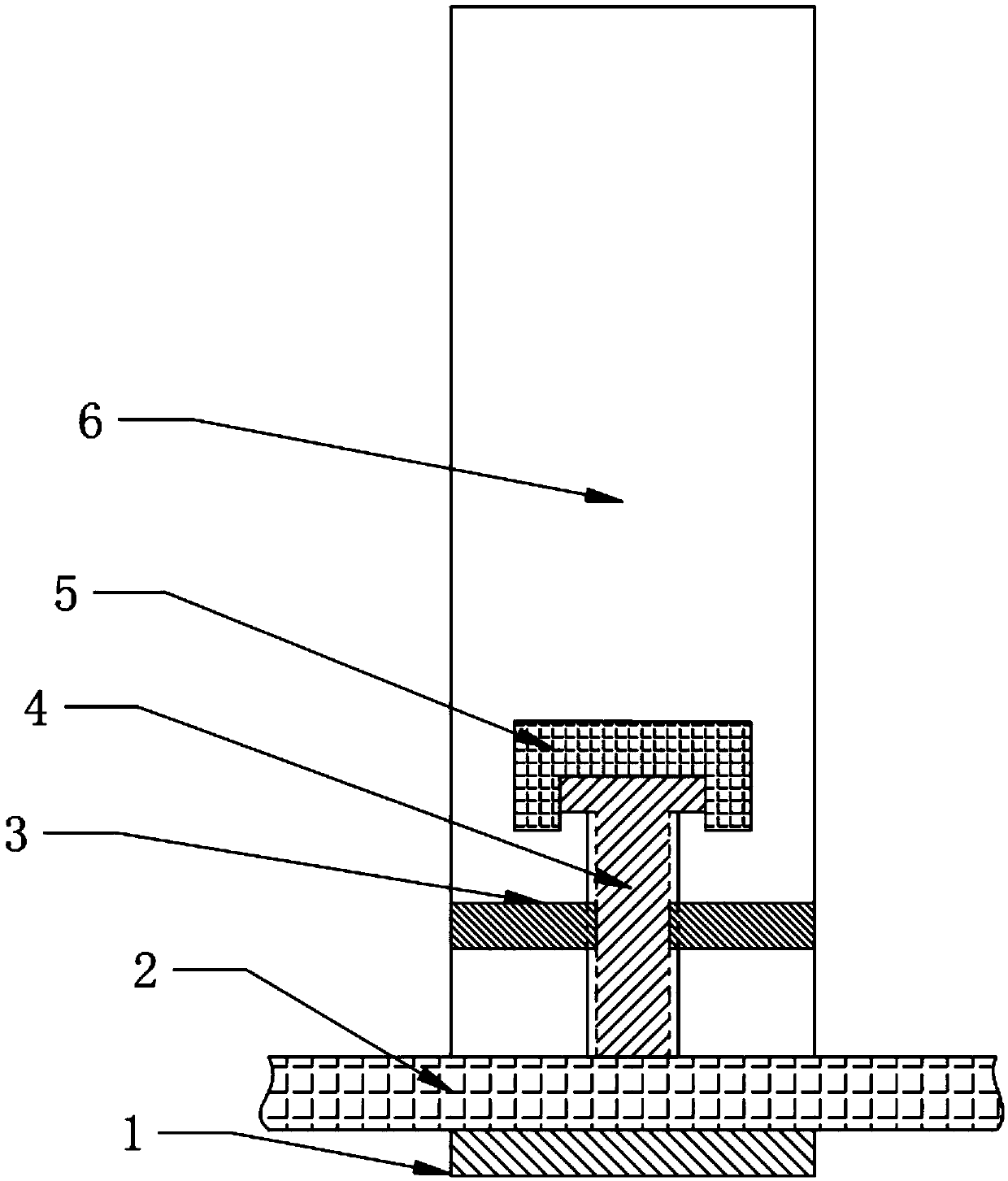

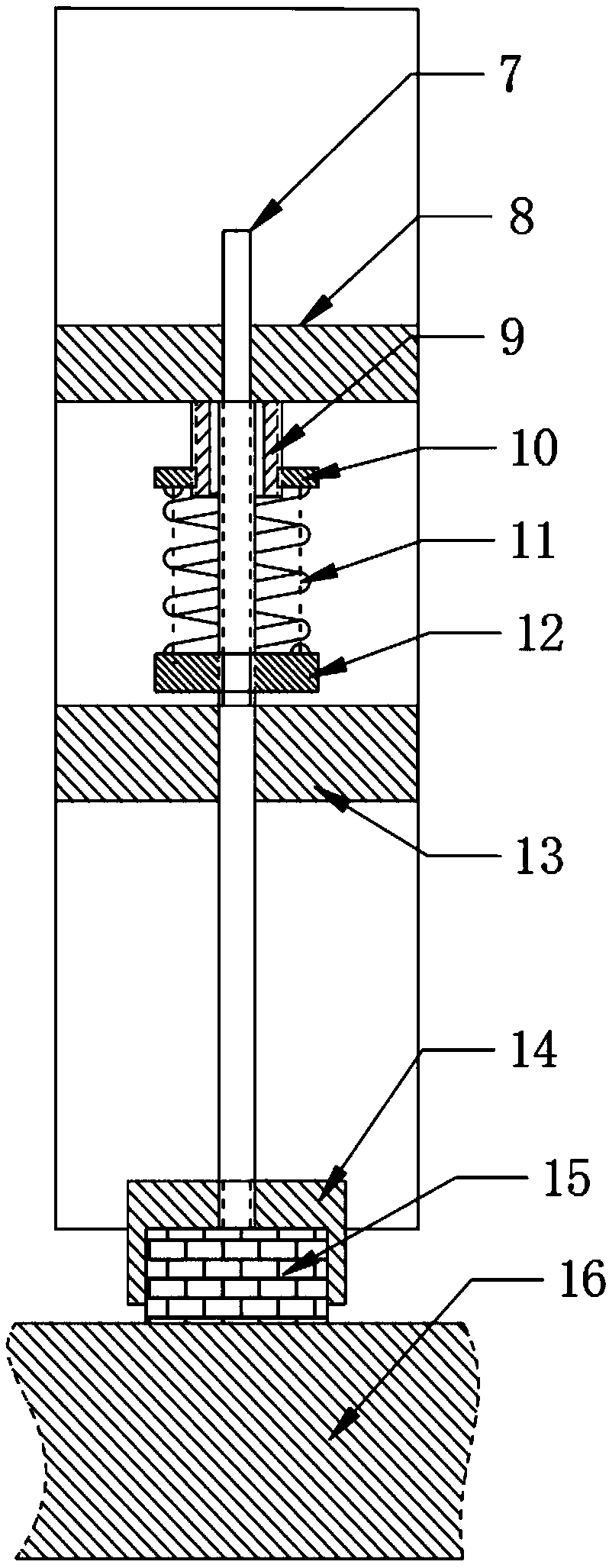

[0022] like figure 1 , the present invention is an auxiliary clamping device for a metallographic grinding and polishing machine, including a cage 6, fixing bolt assemblies 4 and 5, an externally threaded push rod 7, a force nut 10, a hard spring 11, a stop nut 12, a test Sample chuck 14 and other parts.

[0023] An auxiliary clamping device for a metallographic grinding and polishing machine, characterized in that it includes a vertical cage 6, the left side of the cage 6 is connected to the horizontal limit beam 3 and the bottom plate 1, and the bolt 4 is connected to the limit beam 3. The screw holes are engaged, and the lower end of the bolt 4 and the bottom plate 1 clamp the edge steel plate of the operation table of the grinding and polishing machine;

[0024] The right side of the cage 6 connects the upper slideway limit beam 8 and the glideway limit beam...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com