Inflatable anti-explosion tire and processing method thereof

A technology of anti-explosion tires and tires, which is applied in the direction of pneumatic tires, tire parts, tires, etc., can solve the problems of large weight, complex structure, and complex processing of anti-explosion tires, and achieve increased tire weight, enhanced heat transfer effect, and increased ratio The effect of surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

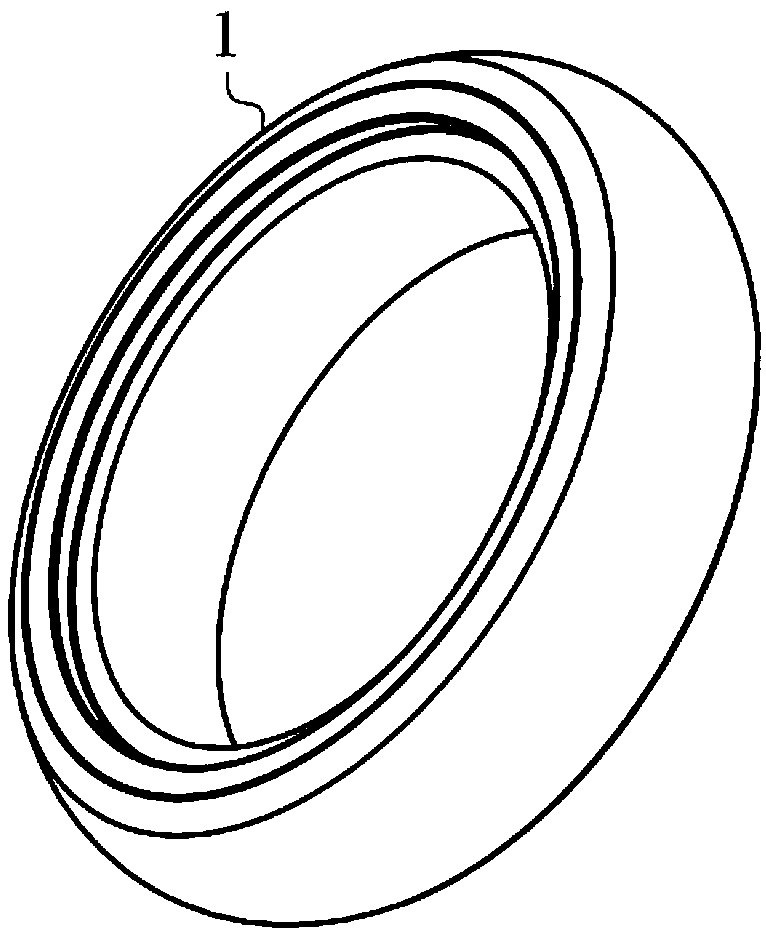

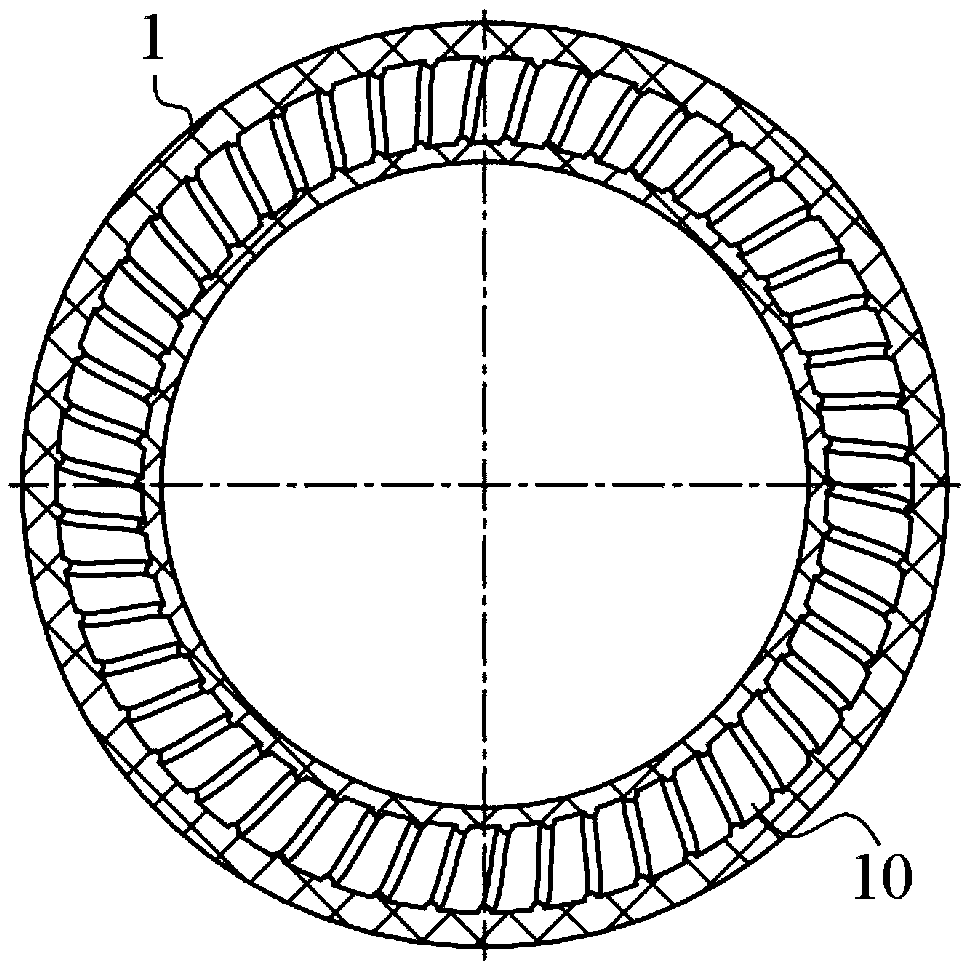

[0054] A kind of inflatable run-flat tire of the present embodiment, as figure 1 , figure 2 with Figure 5 As shown, it includes a tire 1, which is characterized in that: the tire 1 is provided with an inner cavity 10, and the surface of the inner cavity 10 is surrounded by spiral ribs.

[0055] There are generally four reasons for tire blowouts. One is tire air leakage, which is caused by the tire itself being damaged or punctured. The other is that the tire pressure is too high. High-speed driving causes the temperature of the tire to rise and cannot dissipate heat in time. The air pressure in the tire will increase, resulting in tire deformation and blowout; the third is that the tire air pressure is insufficient, which may easily cause a large resonance force, and may cause the tire wall to burst when turning; the fourth is the performance of the tire itself, and the balance of tire manufacturing is not enough The main reason for the accident caused by a tire blowout is...

Embodiment 2

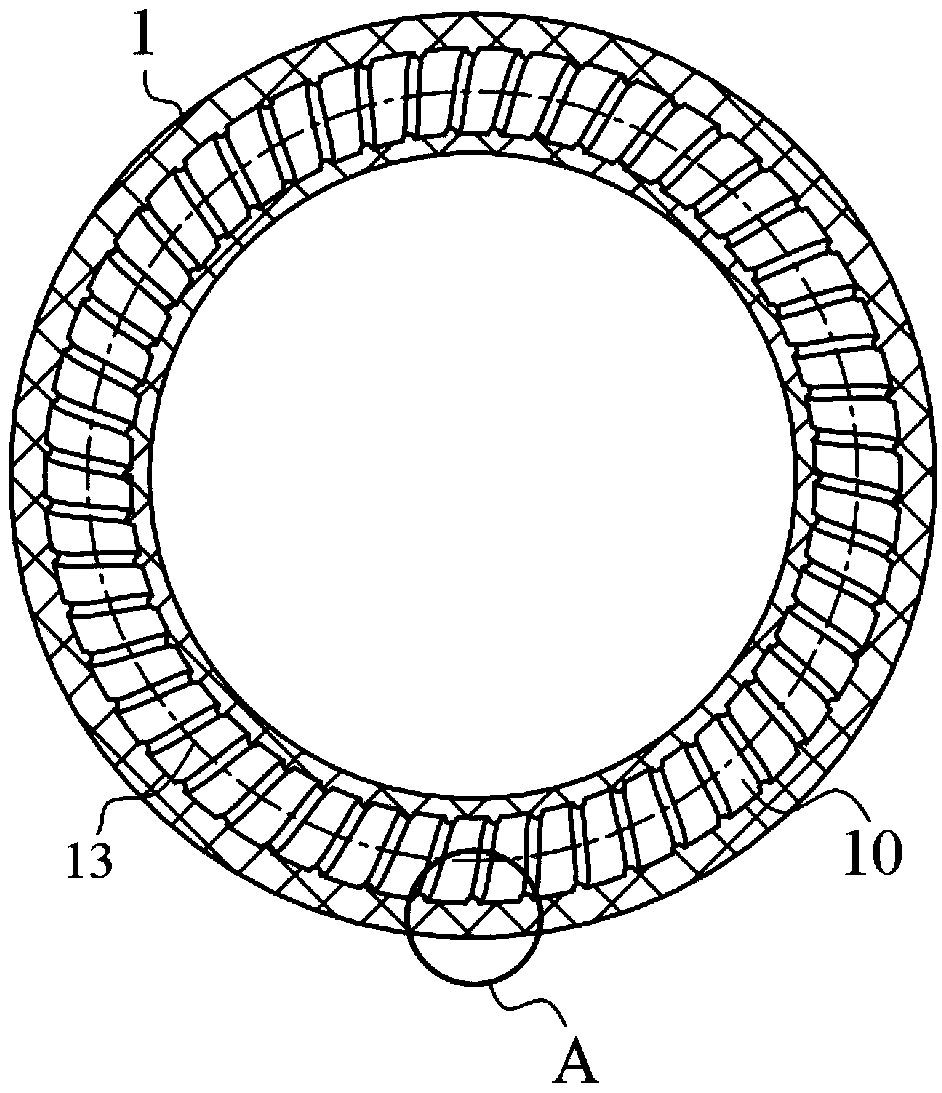

[0060] The inflatable run-flat tire of this embodiment is further improved on the basis of Embodiment 1, and the spiral ridges circle around the central axis 13 of the inner cavity in the circular direction on the surface of the inner cavity 10 to cover the inner cavity 10 for a week .

[0061] Such as image 3 As shown, the embossed pattern is spirally arranged on the surface of the inner cavity 10 in the manner shown in the figure. While enhancing the heat dissipation effect and eliminating the structural stress, the embossed pattern surrounds the inner cavity 10 of the tire like a spring, forming a spring skeleton against the inner cavity 10. It plays a certain supporting role. When the tire is punctured by external force, under the action of the spiral ribs arranged in this embodiment, the threads near the puncture hole evenly disperse the force generated during the puncture, preventing the tire from being punctured. When it breaks, it deforms suddenly, and the helical ri...

Embodiment 3

[0063] The inflatable run-flat tire of this embodiment is further improved on the basis of Embodiment 2, and the surface of the inner cavity 10 is provided with at least one spiral rib.

[0064] In the inflatable run-flat tire of this embodiment, the strength of the surface of the inner cavity 10 is further strengthened by providing a plurality of non-intersecting spiral ribs on the surface of the inner cavity 10, so as to enhance the anti-deformation ability of the tire when it is punctured or air leaks ; Multiple inner cavities 10 can also be set, and the surface of each inner cavity 10 is provided with spiral reliefs to achieve the same effect.

[0065] The inflatable explosion-proof tire of this embodiment has higher strength and stronger tire explosion-proof ability, but the manufacturing cost is increased. The inflatable explosion-proof tire of this embodiment can also be installed and used without inflation, and the spiral relief can be used. Support the carcass and pre...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com