Device and method for preventing steam turbine shaft seal from leakage

A technology of shaft seal leakage and steam turbine, which is applied in the direction of leakage prevention, mechanical equipment, engine components, etc., can solve the problems of complex structure of steam turbine shaft seal system, large clearance of steam turbine shaft seal, and increased leakage of shaft seal. Overcoming the loss of steam working medium and vacuum drop, low equipment purchase and installation costs, and improved sealing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further described in detail below in conjunction with the accompanying drawings and examples. The following examples are explanations of the present invention and the present invention is not limited to the following examples.

[0017] Example.

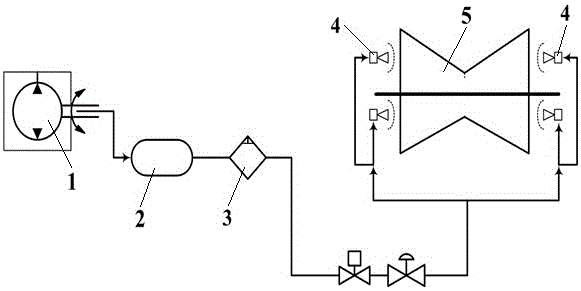

[0018] see figure 1 In this embodiment, the steam turbine shaft seal steam leakage prevention device includes a steam turbine 5 provided with a shaft seal system, a valve, and an air compressor 1 for producing high-pressure air, for storing the high-pressure air produced by the air compressor 1 and controlling the high-pressure air. The air storage tank 2 for stabilizing the pressure, the air dryer 3 used to fully dry the high-pressure air output from the air storage tank 2, used to spray air to the shaft sealing system of the steam turbine 5 and form high-pressure air outside the shaft sealing system Nozzle group 4 at the shaft seal gap in order to prevent the shaft seal system from leaking seali...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com