Variable aircraft flexible wing, variable stiffness skin structure and preparation method thereof

A technology of flexible wings and morphing aircraft, which is applied in the directions of wings, aircraft parts, transportation and packaging, etc. It can solve the problems of heavy mass, low efficiency, and long response time of drive units, achieve high elastic energy density, and overcome deformation The effect of slow, short response times

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

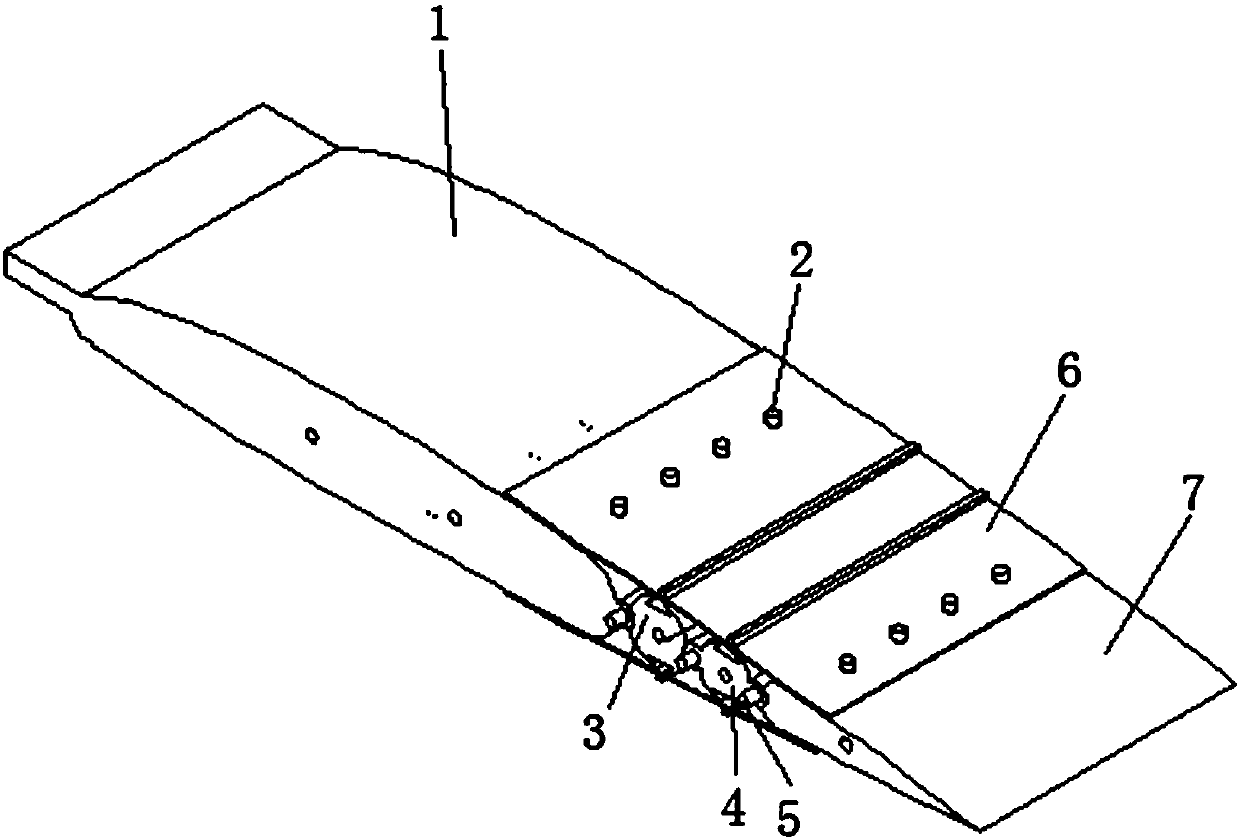

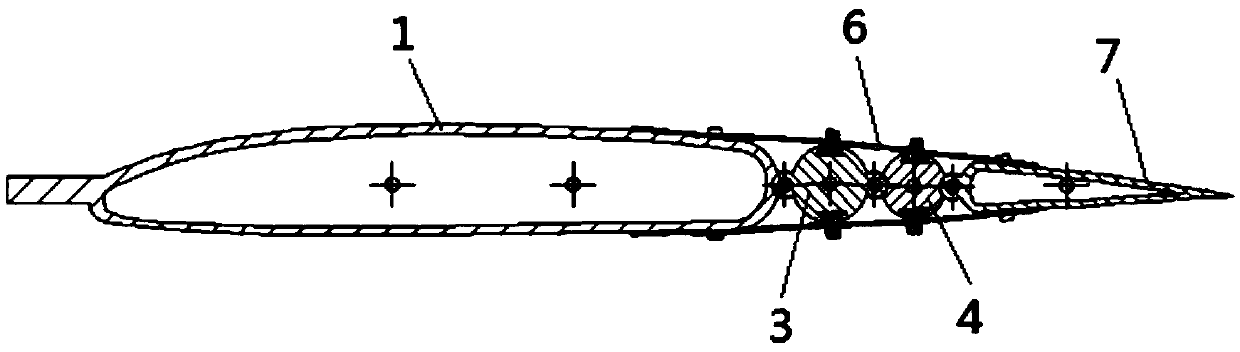

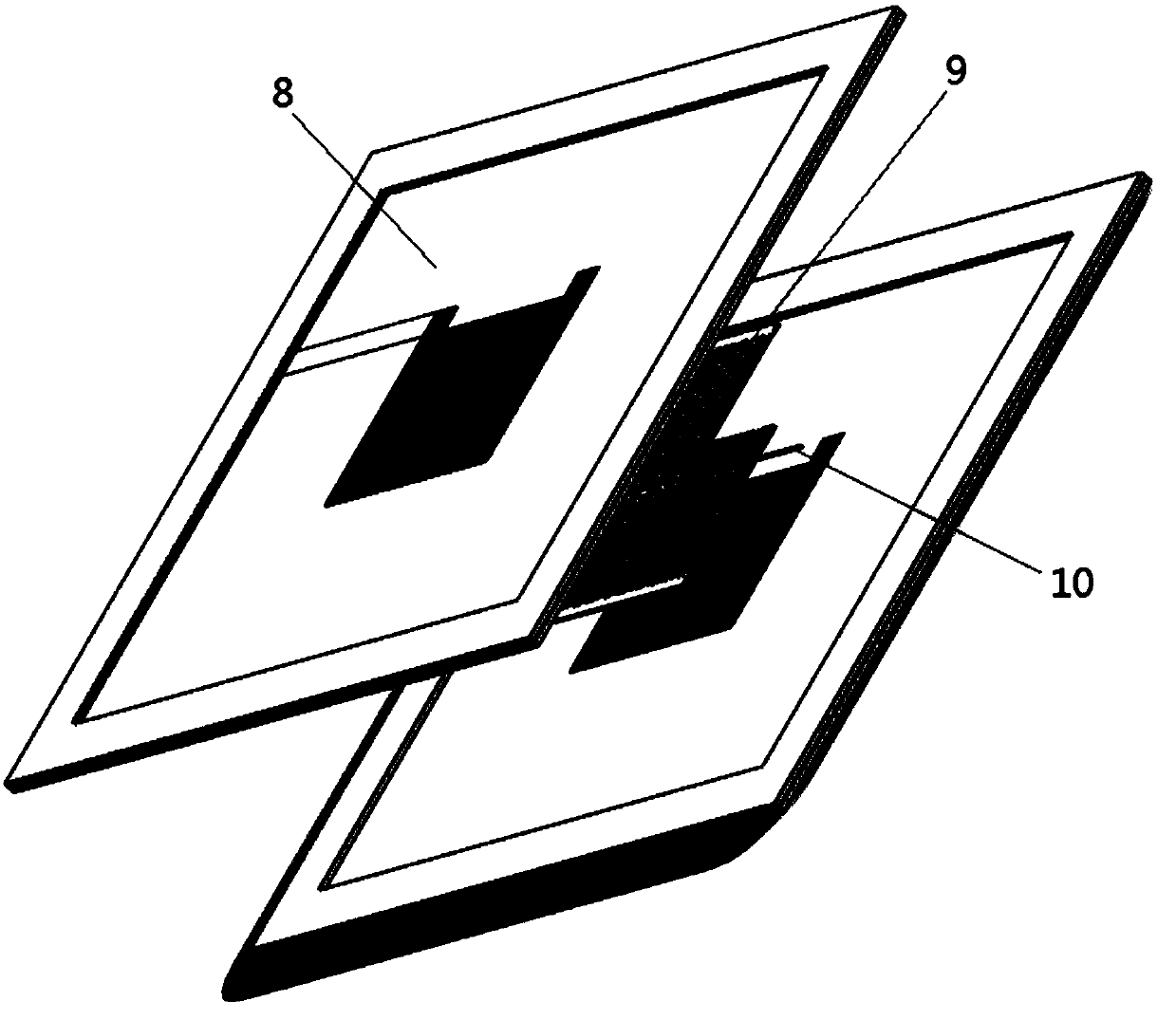

[0031] see Figure 1 to Figure 3 , a variant aircraft flexible wing of the present invention, comprising: wing skeleton and variable stiffness skin unit 6 . The wing skeleton is formed by connecting the inner wing 1, the first cylindrical hinge 3, the second cylindrical hinge 4, and the outer wing 7 through the connecting shaft 5, and the variable stiffness skin unit 6 is fixed on both sides of the wing skeleton by fixing pins 2 and The wing skeleton is assembled into a complete skin structure. The specific connection relationship is as follows: the inner wing 1 is connected together with the first cylindrical hinge 3 through the connecting shaft 5, the first cylindrical hinge 3 is connected with the second cylindrical hinge 4 through the connecting shaft 5, and the second cylindrical hinge 4 is connected through the connecting shaft...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com