Dielectric elastomer folding-shaped driver and making method thereof

A technology of a dielectric elastomer and a manufacturing method, which is applied in the directions of generators/motors, electrostatic generators/motors, electrical components, etc., can solve the problems of large volume, high noise, and poor biocompatibility.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

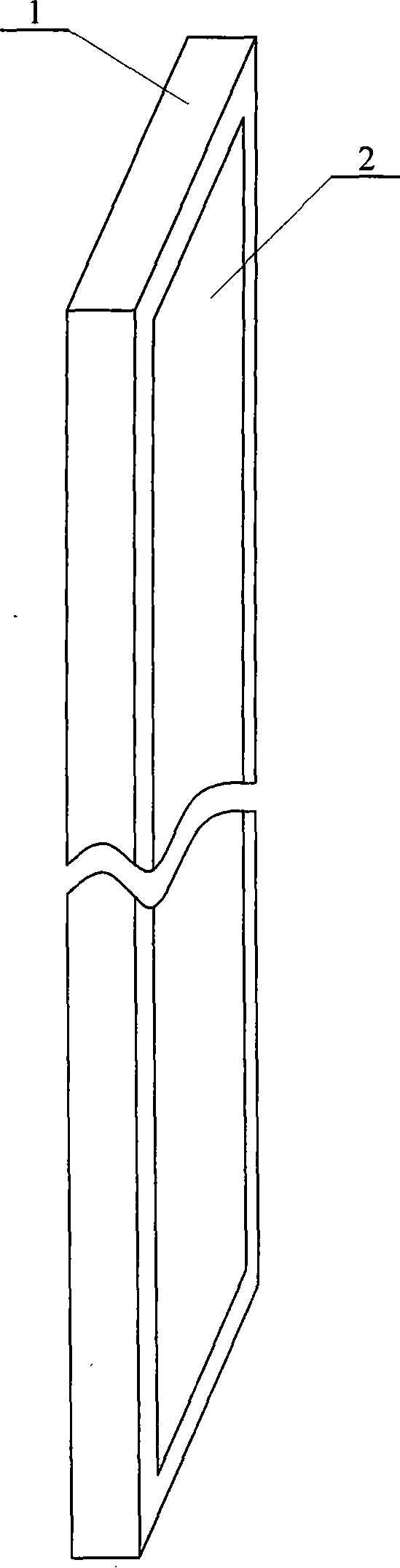

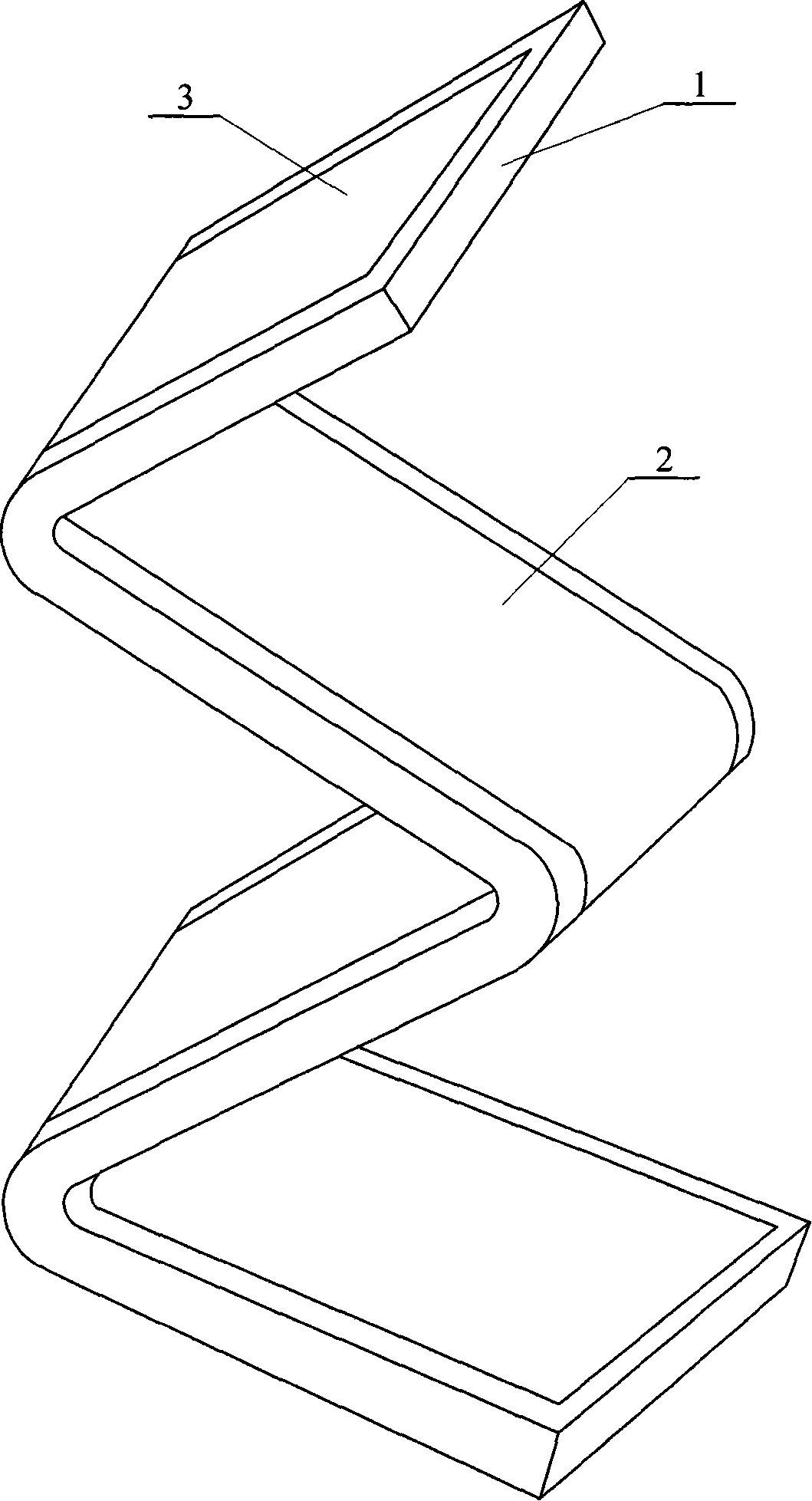

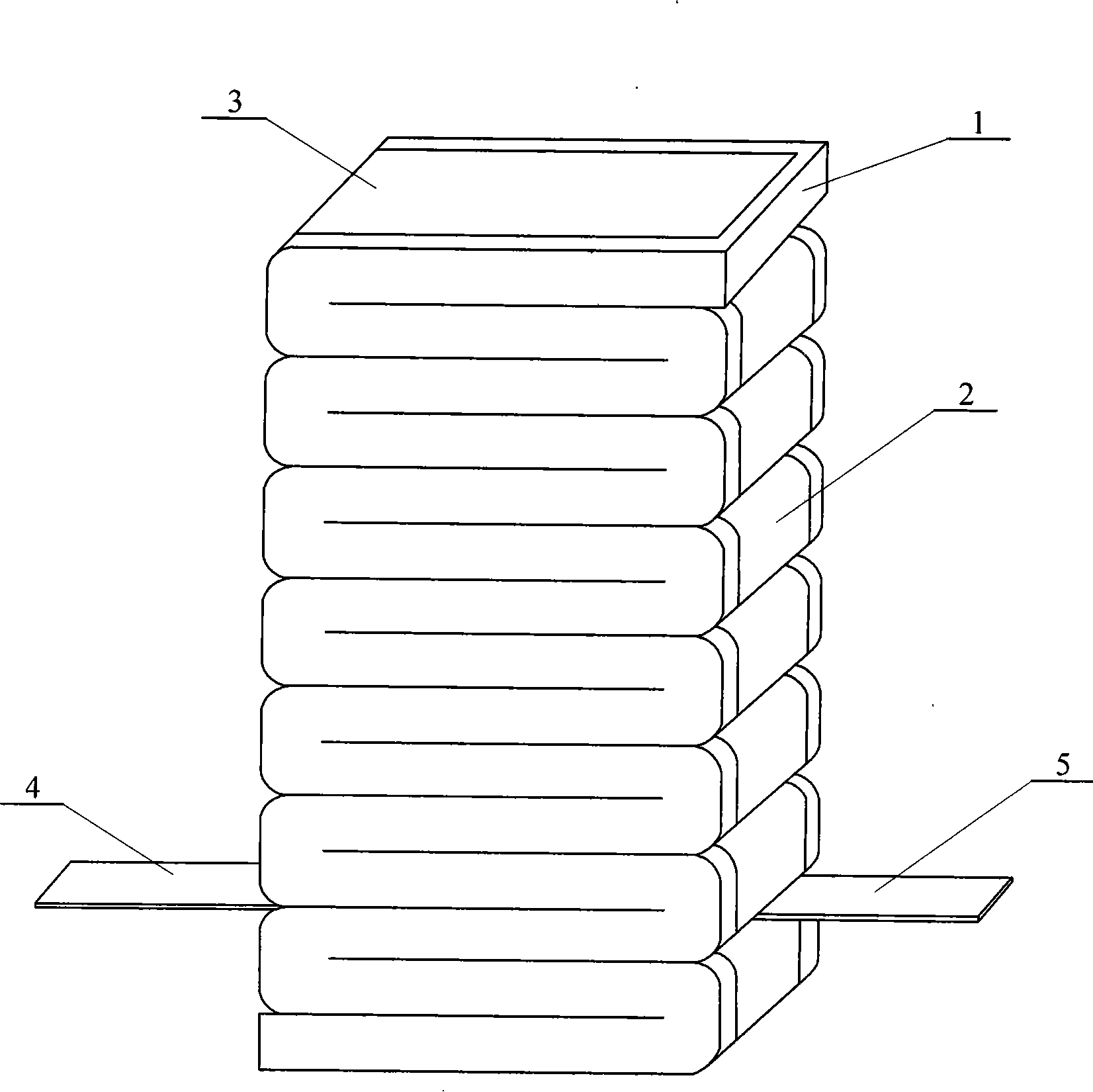

[0005] Specific implementation mode one: (see Figure 1 ~ Figure 3 ) The dielectric elastomer folding driver of this embodiment is composed of a dielectric elastomer film 1, a first flexible electrode 2, a second flexible electrode 3, a first aluminum foil 4 and a second aluminum foil 5, and the dielectric elastomer film 1 One side of the surface is coated with the first flexible electrode 2, and the other side surface of the dielectric elastomer film 1 is coated with the second flexible electrode 3, and the dielectric elastomer with the first flexible electrode 2 and the second flexible electrode 3 The film 1 is sequentially folded into a cuboid shape, the first aluminum foil 4 is connected to the second flexible electrode 3 , and the second aluminum foil 5 is connected to the first flexible electrode 2 .

specific Embodiment approach 2

[0006] Specific implementation mode two: (see Figure 1 ~ Figure 3 ) The material of the first flexible electrode 2 in this embodiment is graphite. Others are the same as in the first embodiment.

specific Embodiment approach 3

[0007] Specific implementation mode three: (see Figure 1 ~ Figure 3 ) The material of the second flexible electrode 3 in this embodiment is graphite. Others are the same as in the first embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com