Matte type high-barrier flat-bottom-zipper nut packaging bag and preparation method thereof

A high-barrier, packaging bag technology, applied in the field of packaging bags, can solve the problems of not being able to meet the sealing requirements of snacks, affecting the graphic display of packaging bags, and poor mechanical strength and sealing, achieving a strong sense of graphic layering, improving upright stability, The effect of improving airtightness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

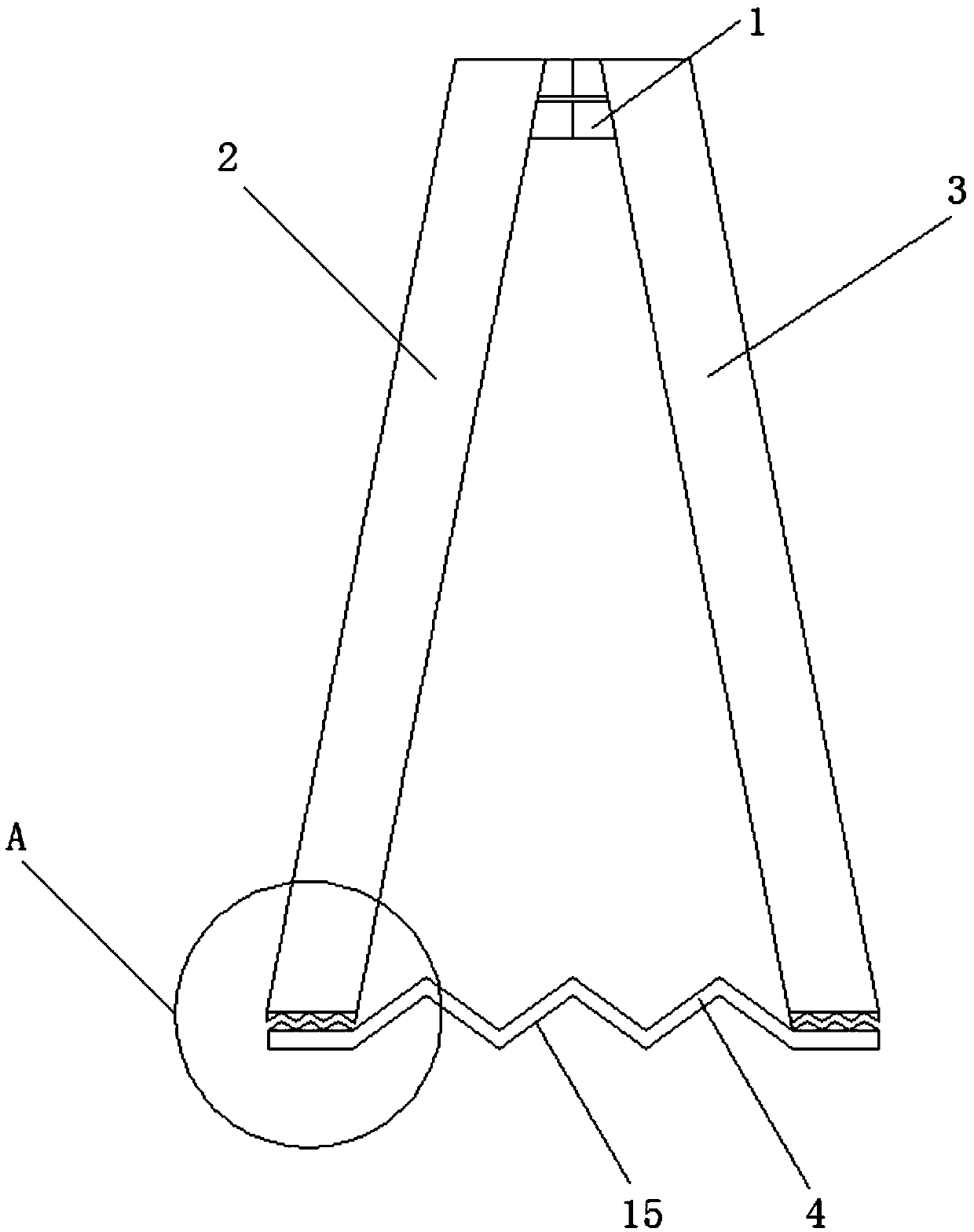

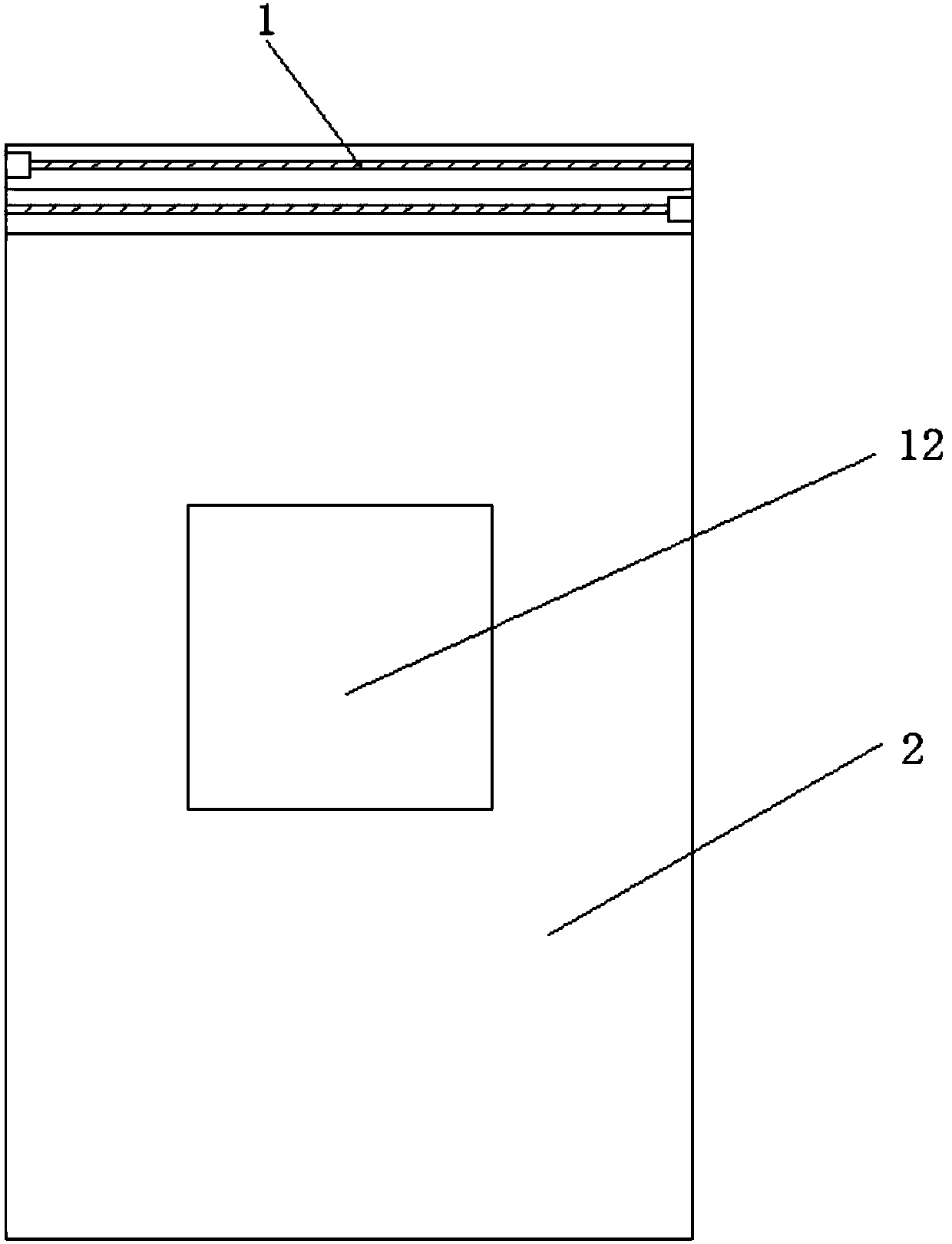

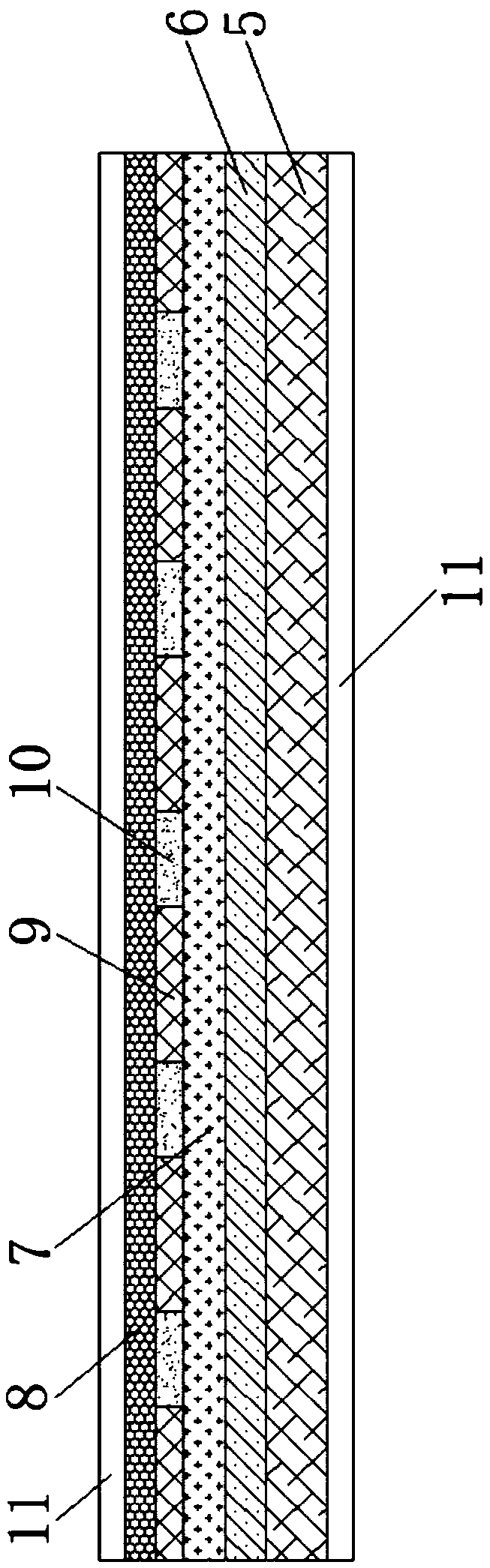

[0037] according to figure 1 , 2 , 3, and 4, the present embodiment proposes a matte type high-barrier flat bottom zipper nut packaging bag, including a bag body and a sealed zipper strip 1, and the bag body is composed of a front bag body 2, a rear bag body 3 and a bottom layer 4, Both sides of the bottom layer 4 are respectively provided with a front bag body 2 and a rear bag body 3, the upper ends of the front bag body 2 and the rear bag body 3 are connected by a sealed zipper strip 1, and the front bag body 2, the rear bag body 3 and the The bottom layer 4 has the same composition and structure, and the front bag body includes a base layer 5, an aluminum layer 6, a high barrier polypropylene film layer 7, an adhesive layer 8, an ink layer 9, a matte layer 10 and a heat-sealing film layer 11, The outer side of the base layer 5 is provided with an aluminum-coated layer 6, the aluminum-coated layer 6 is provided with a blank area 12, and the outer side of the aluminum-coated...

Embodiment 2

[0058] according to figure 1 , 2 , 3, and 4, the present embodiment proposes a matte type high-barrier flat bottom zipper nut packaging bag, which is characterized in that: it includes a bag body and a sealed zipper strip 1, and the bag body is composed of a front bag body 2, a rear bag body 3 and The bottom layer 4 is composed of a front bag body 2 and a rear bag body 3 respectively on both sides of the bottom layer 4, and the upper ends of the front bag body 2 and the rear bag body 3 are connected by a sealed zipper strip 1. The composition and structure of the bag body 3 and the bottom layer 4 are the same. The front bag body includes a base layer 5, an aluminized layer 6, a high-barrier polypropylene film layer 7, an adhesive layer 8, an ink layer 9, a matte layer 10 and a heat-sealed layer. Film layer 11, the outer side of the base layer 5 is provided with an aluminum-coated layer 6, and the aluminum-coated layer 6 is provided with a blank area 12, and the outer side of ...

Embodiment 3

[0079] according to figure 1 , 2 , 3, and 4, the present embodiment proposes a matte type high-barrier flat bottom zipper nut packaging bag, which is characterized in that: it includes a bag body and a sealed zipper strip 1, and the bag body is composed of a front bag body 2, a rear bag body 3 and The bottom layer 4 is composed of a front bag body 2 and a rear bag body 3 respectively on both sides of the bottom layer 4, and the upper ends of the front bag body 2 and the rear bag body 3 are connected by a sealed zipper strip 1. The composition and structure of the bag body 3 and the bottom layer 4 are the same. The front bag body includes a base layer 5, an aluminized layer 6, a high-barrier polypropylene film layer 7, an adhesive layer 8, an ink layer 9, a matte layer 10 and a heat-sealed layer. Film layer 11, the outer side of the base layer 5 is provided with an aluminum-coated layer 6, and the aluminum-coated layer 6 is provided with a blank area 12, and the outer side of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com