A kind of antibacterial concentrated washing powder and preparation method thereof

A technology of concentrated washing powder and antibacterial agent, which is applied in the field of daily necessities, can solve problems such as easy breeding of bacteria on clothes and threats to people's health, and achieve good emulsification and dispersion, good antibacterial effect, and improved decontamination effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

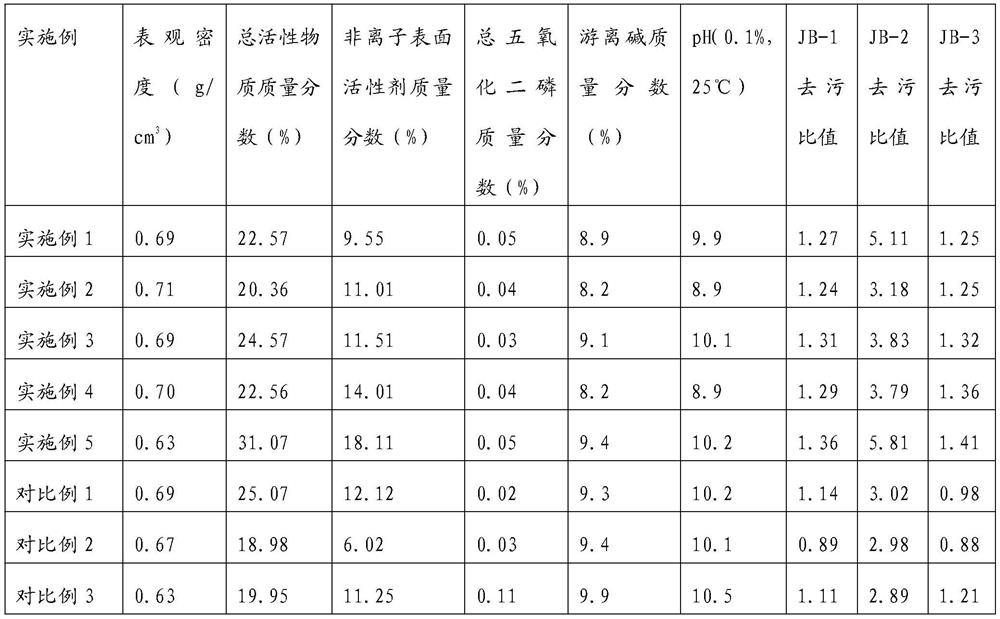

Examples

Embodiment 1

[0027] An antibacterial concentrated laundry powder, comprising the following components in parts by weight: 3.5 parts of isomeric tridecanol polyoxyethylene (9) ether, 2 parts of cocamide methyl MEA, fatty alcohol polyoxyethylene (9) ether 4 parts, 11 parts of sodium α-alkenyl sulfonate (powder, 97% content), 3 parts of sodium fatty acid methyl ester sulfonate (powder, 80% content), 5 parts of sodium citrate, two parts of methyl glycine 1 part of trisodium acetate, 3 parts of layered sodium silicate, 20 parts of sodium carbonate, 1 part of maleic acid-acrylic acid copolymer sodium salt, 5 parts of 4A zeolite, 0.1 parts of 1,2-benzisothiazolin-3-one 0.4 parts of 4,4-dichloro-2-hydroxydiphenyl ether, 0.1 parts of essence, 0.9 parts of protease, 0.7 parts of lipase, and 39.3 parts of sodium sulfate.

Embodiment 2

[0029] An antibacterial concentrated laundry powder, comprising the following components in parts by weight: 3 parts of isomeric tridecanol polyoxyethylene (9) ether, 3 parts of cocamide methyl MEA, fatty alcohol polyoxyethylene (9) ether 5 parts, 8 parts of sodium α-alkenyl sulfonate (powder, 97% content), 2 parts of sodium fatty acid methyl ester sulfonate (powder, 80% content), 1 part of sodium citrate, two parts of methyl glycine 1 part of trisodium acetate, 3 parts of layered sodium silicate, 10 parts of sodium carbonate, 3 parts of maleic acid-acrylic acid copolymer sodium salt, 16 parts of 4A zeolite, 0.2 parts of 1,2-benzisothiazolin-3-one 0.5 parts of 4,4-dichloro-2-hydroxydiphenyl ether, 0.2 parts of essence, 0.3 parts of protease, 0.1 part of lipase, and 43.7 parts of sodium sulfate.

[0030] Its preparation method comprises the following steps:

[0031] (1) Isomerized tridecyl alcohol polyoxyethylene (9) ether, cocamide methyl MEA, fatty alcohol polyoxyethylene (9...

Embodiment 3

[0035] An antibacterial concentrated laundry powder, comprising the following components in parts by weight: 4 parts of isomeric tridecanol polyoxyethylene (9) ether, 2 parts of cocamide methyl MEA, fatty alcohol polyoxyethylene (9) ether 5.5 parts, 11 parts of sodium α-alkenyl sulfonate (powder, 97% content), 3 parts of sodium fatty acid methyl ester sulfonate (powder, 80% content), 3 parts of sodium citrate, two parts of methyl glycine 3 parts of trisodium acetate, 5 parts of layered sodium silicate, 25 parts of sodium carbonate, 3 parts of maleic acid-acrylic acid copolymer sodium salt, 8 parts of 4A zeolite, 0.3 parts of 1,2-benzisothiazolin-3-one 0.6 parts of 4,4-dichloro-2-hydroxydiphenyl ether, 0.4 parts of essence, 0.5 parts of protease, 0.1 part of lipase, and 25.6 parts of sodium sulfate.

[0036] Its preparation method comprises the following steps:

[0037] (1) Isomerized tridecyl alcohol polyoxyethylene (9) ether, cocamide methyl MEA, fatty alcohol polyoxyethylen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com