Improved OLED evaporation device and method for improving evaporation shadow effect

A technology of evaporation and evaporation source, applied in the field of OLED evaporation, can solve problems such as unsatisfactory effect, and achieve the effect of eliminating shadow effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

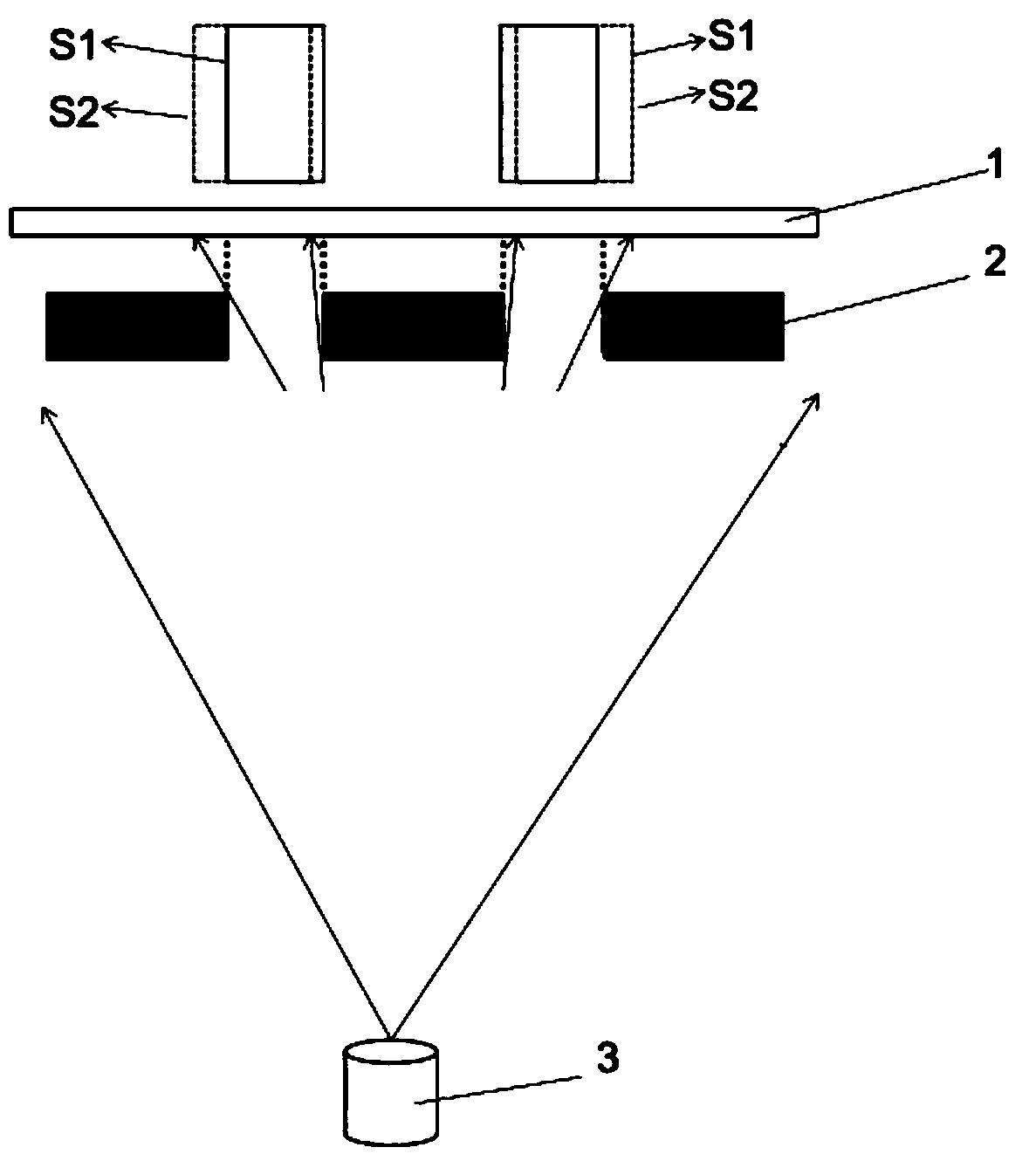

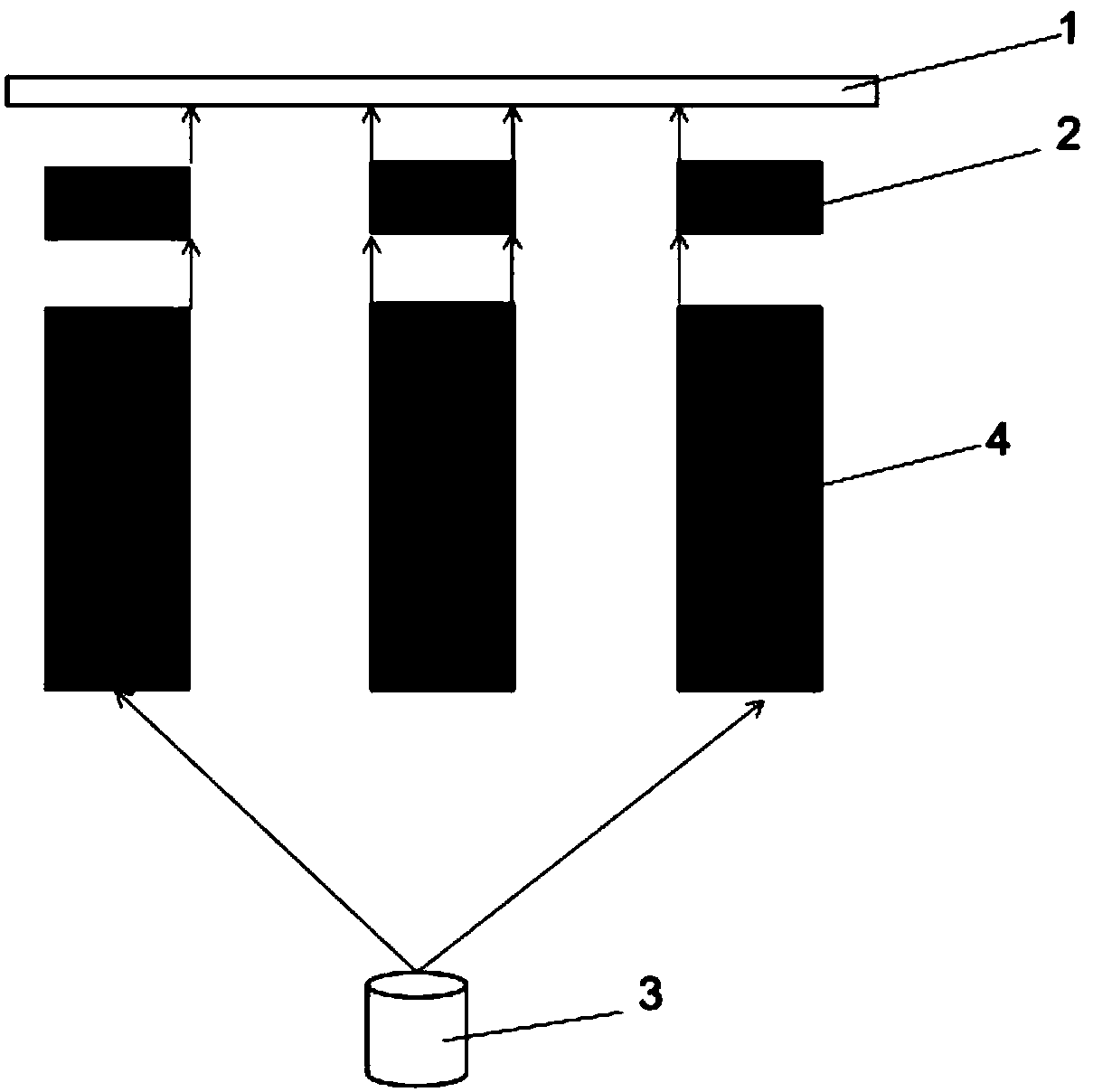

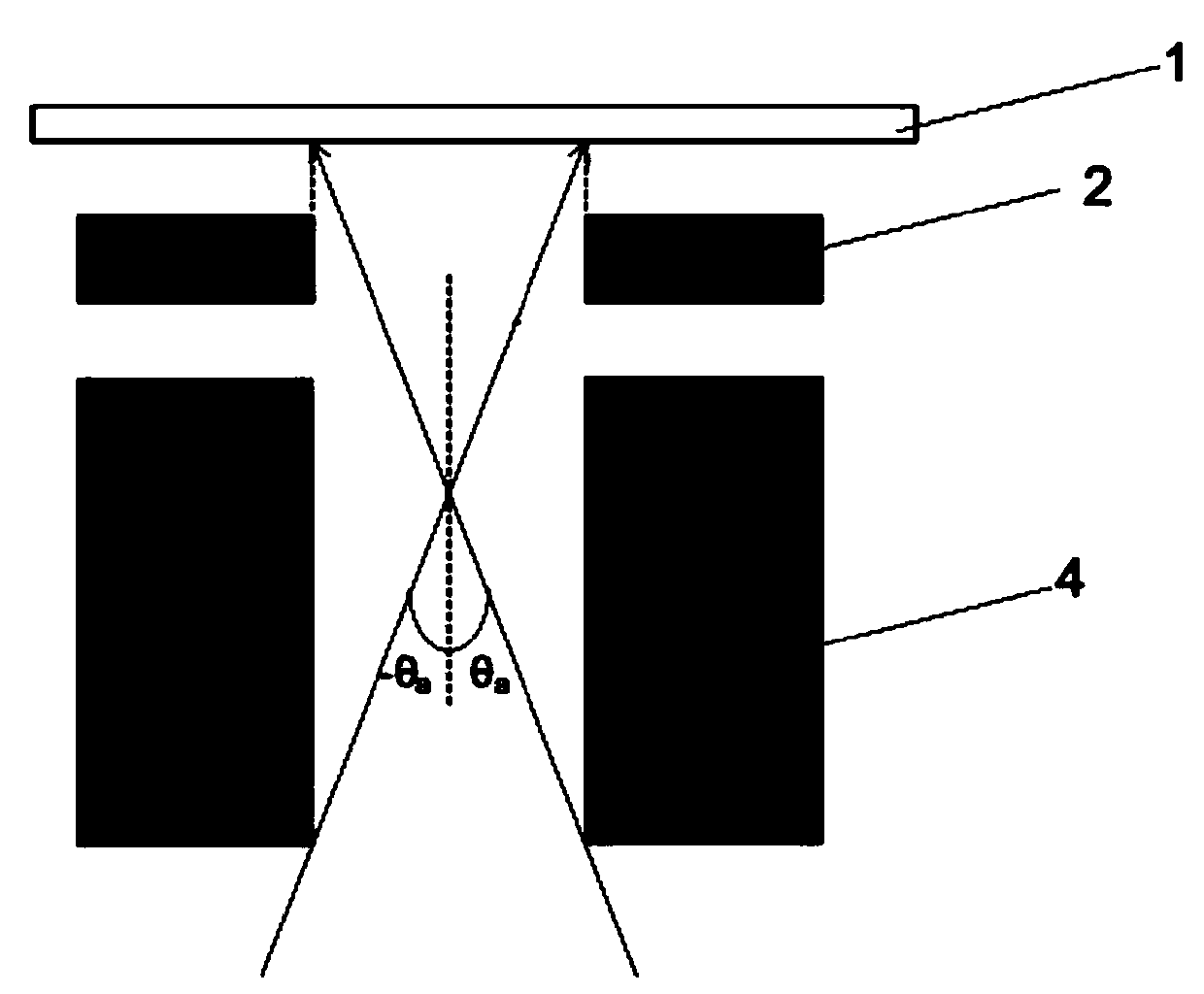

[0027] Such as Figures 2 to 5 As shown, an improved OLED evaporation device includes a substrate 1, a mask plate 2 and an evaporation source 3 arranged in sequence from top to bottom, and a collimation filter 4 is arranged below the mask plate 2, and the The collimation filter 4 includes several channels 5 , and each channel 5 of the collimation filter 4 is arranged in alignment with the corresponding opening on the mask plate 2 above it.

[0028] In this embodiment, the collimation filter 4 is made of metal, glass, polymer or semiconductor material. The channel 5 has a high aspect ratio, and generally the height of the channel 5 is more than five times its width (square opening). The opening of the channel 5 has the same shape and size as the opening of the mask plate 2 .

[0029] The mask 2 is a fine metal mask made of Invar alloy.

[0030] The present invention also provides a method for improving the evaporation shadow effect of an improved OLED evaporation device. The...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com