Inclined tooth planet gear and ball combined speed reducer

A planetary gear, combined technology, applied in the direction of gear transmission, gear lubrication/cooling, belt/chain/gear, etc., can solve the problems of low transmission efficiency of planetary reducer, inability to meet modern production, large transmission ratio error, etc. Achieve the effect of improving transmission efficiency, low friction and small transmission ratio error

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] In order to facilitate the understanding of those skilled in the art, the present invention will be further described below in conjunction with the embodiments and accompanying drawings, and the contents mentioned in the embodiments are not intended to limit the present invention.

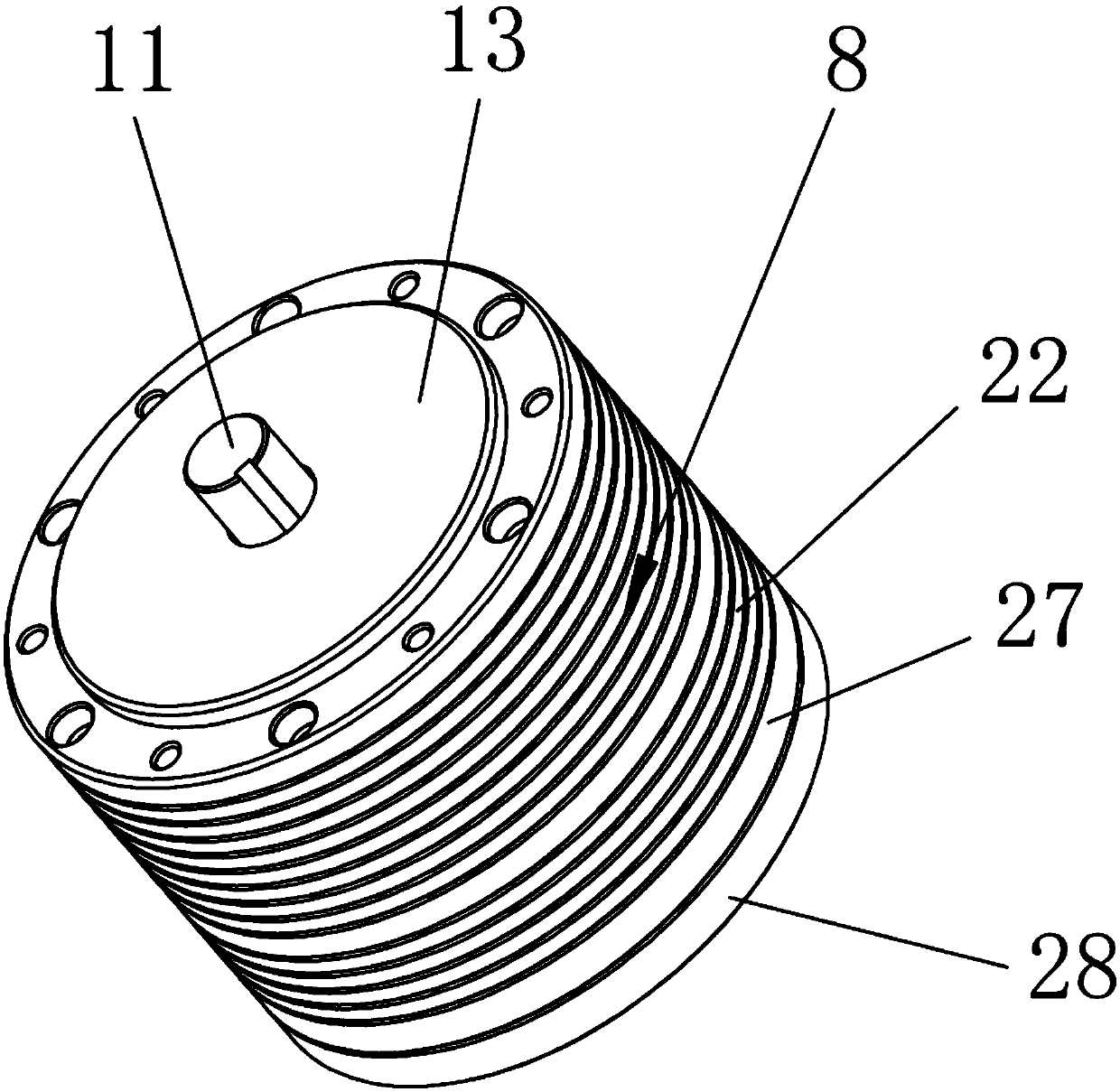

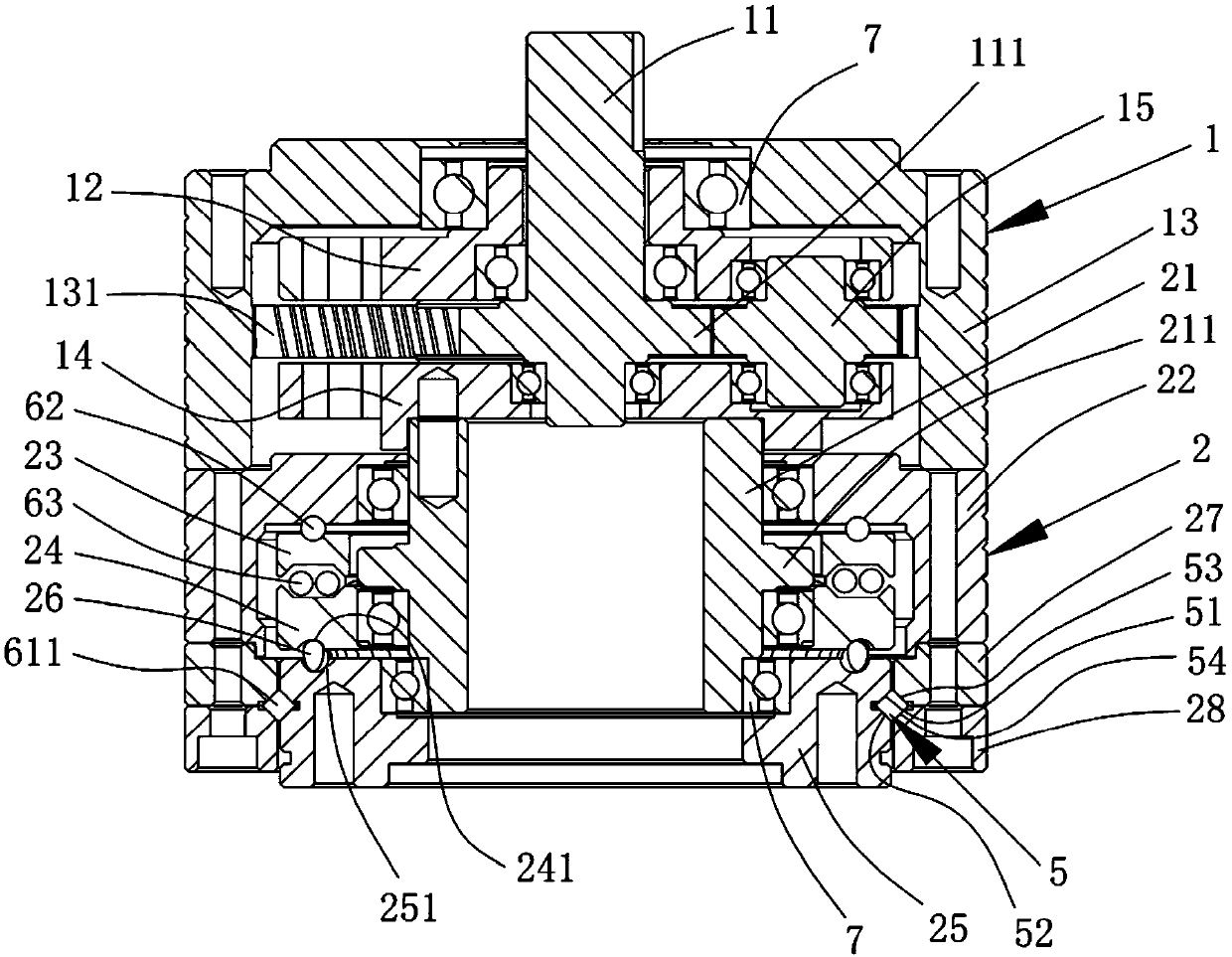

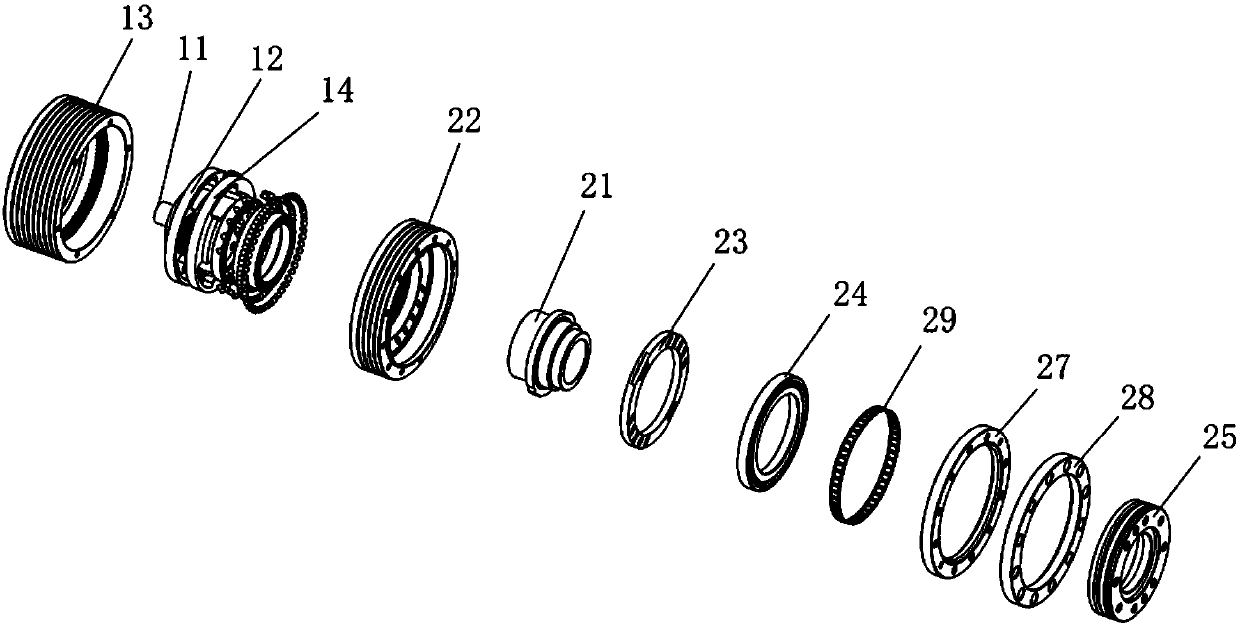

[0035] Such as Figure 1 to Figure 15As shown, the present invention provides a helical planetary gear and ball combined reducer, which includes a planetary gear reduction assembly 1 and a ball reduction assembly 2 that is in transmission connection with the planetary gear reduction assembly 1. The planetary gear reduction assembly 1 includes the first An input shaft 11, a planetary carrier 12, a first housing 13, a first output disc 14, and a plurality of helical planetary gears 15, the first input shaft 11 is fixed with a sun gear 111, and the planetary carrier 12 is rotatably arranged on the first input Shaft 11, a plurality of helical planetary gears 15 are arranged around the sun gear 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com