Optical fingerprint module, screen assembly and electronic device

A fingerprint module and optical technology, applied in computer parts, character and pattern recognition, instruments, etc., can solve the problems of the difference between the actual distance and the design value, affecting the collection of fingerprint optical signals, and the scrap of the module, so as to reduce the defect rate. , reduce the number of parts, reduce the effect of influencing factors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

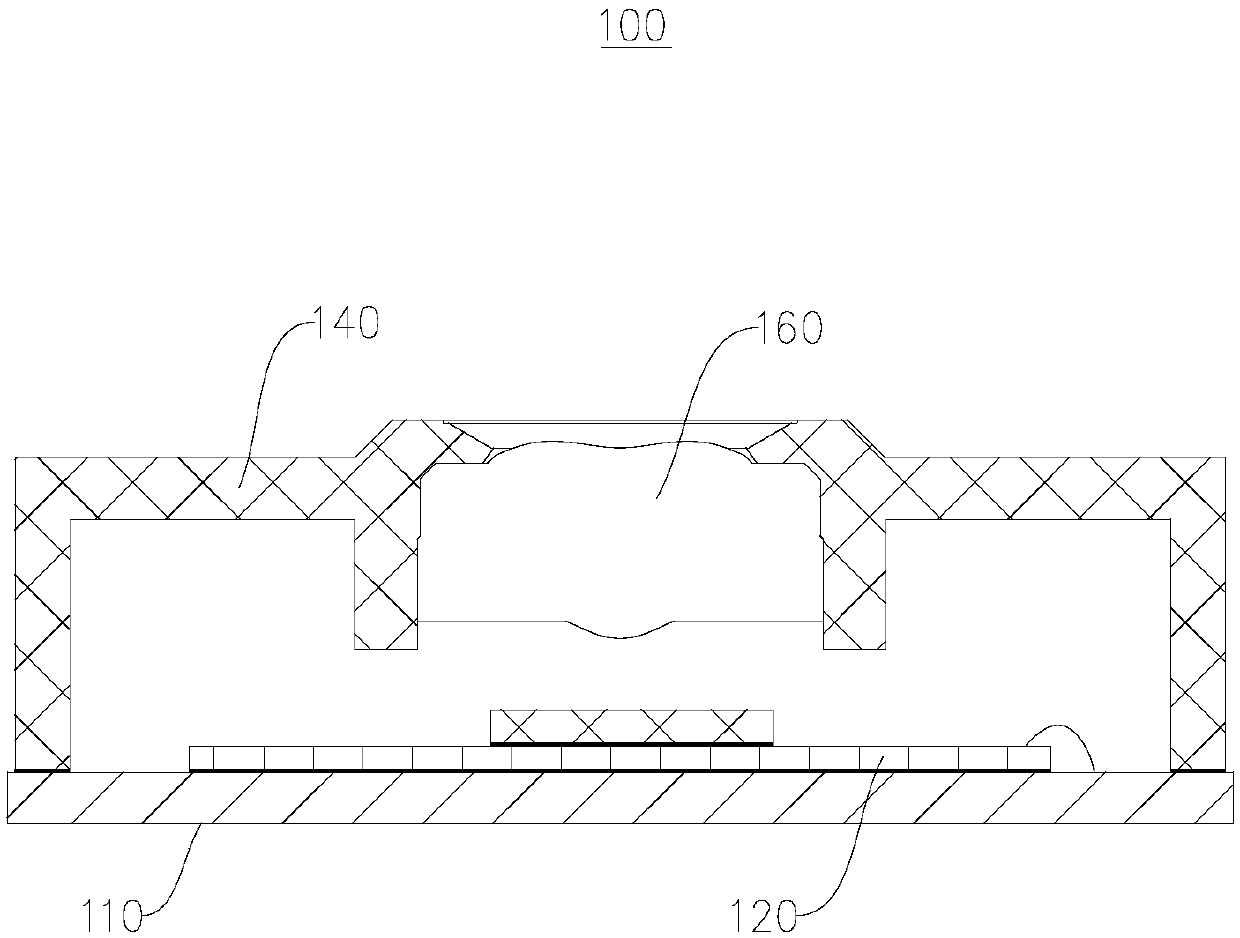

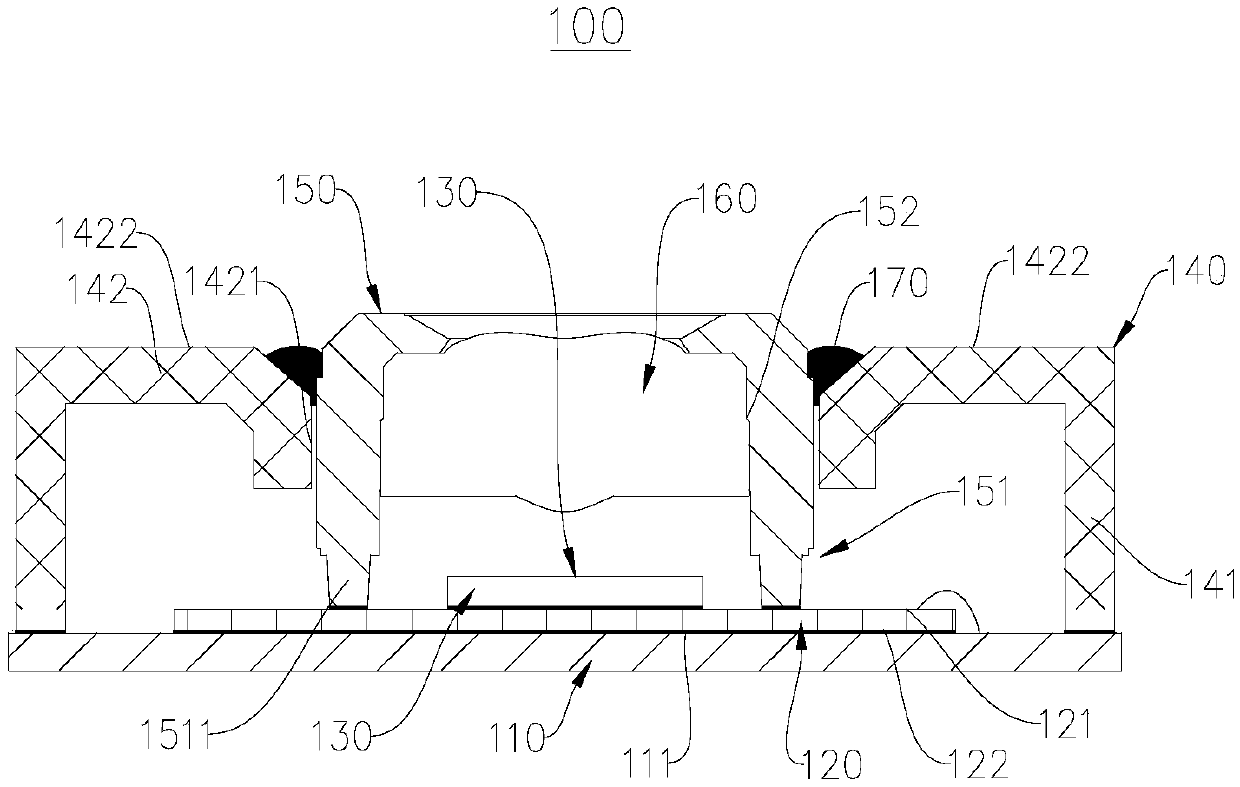

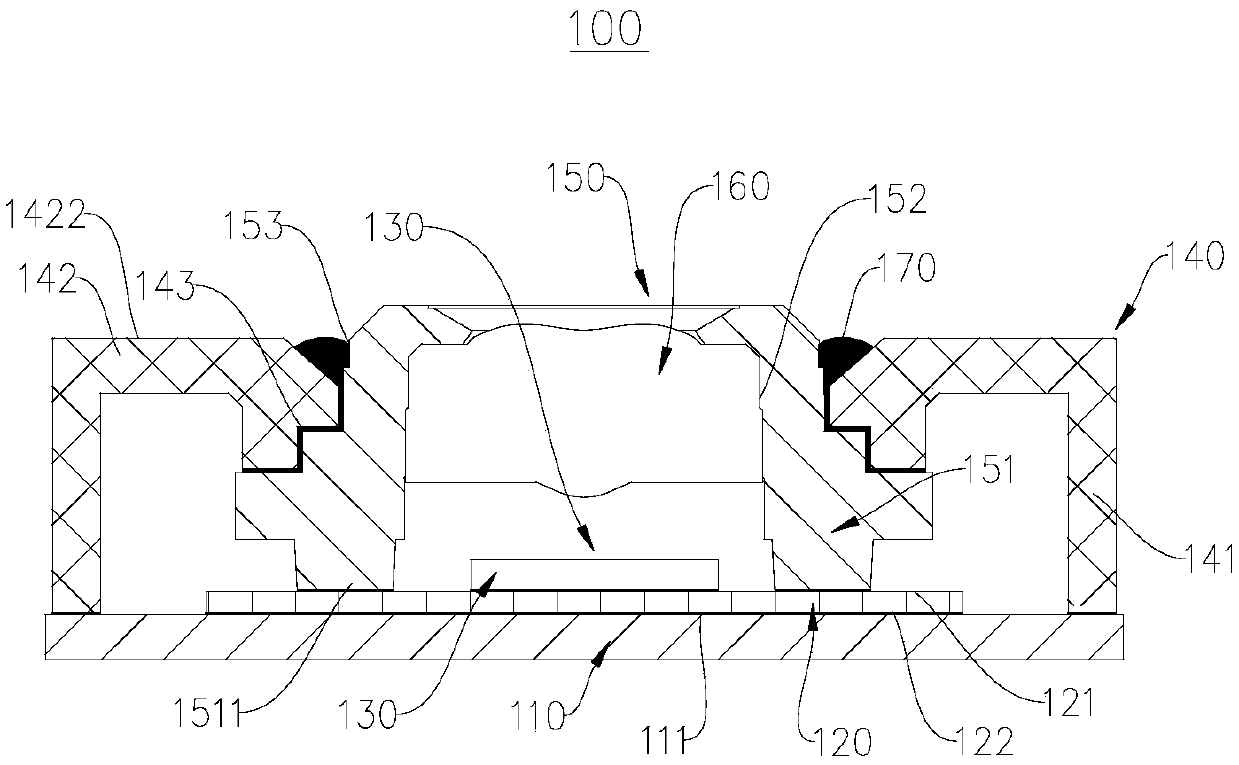

[0035]This embodiment provides an optical fingerprint module 100 to improve the actual distance between the lens 160 and the fingerprint identification chip 120 in the actual manufactured module that may occur in the existing optical fingerprint module 100 and the design value. big difference problem.

[0036] see figure 2 , the optical fingerprint module 100 includes a lens barrel 150 , a lens 160 , a filter 130 , a fingerprint identification chip 120 , a bracket 140 and a circuit substrate 110 .

[0037] The fingerprint identification chip 120 is arranged on the circuit substrate 110, the circuit substrate 110 includes a connection surface 111, the fingerprint identification chip 120 includes a first plane 121 and a second plane 122 opposite to the first plane 121, the first plane 121 of the fingerprint identification chip 120 Including the optical sensing area and the non-optical reaction area, the optical sensing area is used to sense and identify the fingerprint light a...

no. 2 example

[0051] This embodiment provides a screen assembly 200 , the screen assembly 200 includes a display screen 210 and the optical fingerprint module 100 provided in the first embodiment, and the optical fingerprint module 100 is arranged under the display screen 210 .

[0052] Screen assembly 200 is applied to electronic equipment, see Figure 7 , the screen assembly 200 also includes a middle frame 220 and a shielding foam 230. The optical fingerprint module 100 is fixed under the middle frame 220 by adhesive bonding or screw locking. The middle frame 220 is generally used to support and protect the display screen. 210. A shielding foam 230 is used between the middle frame 220 and the display screen 210 to prevent external stray light from interfering with the fingerprint optical signal. The display screen 210 may be an OLED screen, but is not limited thereto, and may also be other display screens 210 with the same or similar functions.

[0053] In another implementation of thi...

no. 3 example

[0055] This embodiment provides an electronic device, and the electronic device provided by this embodiment includes the screen component 200 provided by the second embodiment.

[0056] To sum up, the present invention provides an optical fingerprint module, a screen component and an electronic device. The optical fingerprint module includes: a lens barrel, lenses and a fingerprint recognition chip, the fingerprint recognition chip includes a first plane, the lens barrel includes a connecting portion and a mounting portion away from the connecting portion, the lens is mounted on the The installation part, the connection part is arranged on the first plane of the fingerprint identification chip so that the distance between the lens and the fingerprint identification chip is a preset value. The lens is directly connected to the fingerprint identification chip through the lens barrel, which removes the connection between the lens and the fingerprint identification chip, such as t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com