Method for forming conductive structure

A conductive structure and groove technology, which is applied in the manufacture of circuits, electrical components, semiconductors/solid-state devices, etc., can solve problems such as incomplete filling, easy formation of impurities or defects, and influence on the uniformity of conductive material growth. performance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described below in conjunction with the drawings and embodiments.

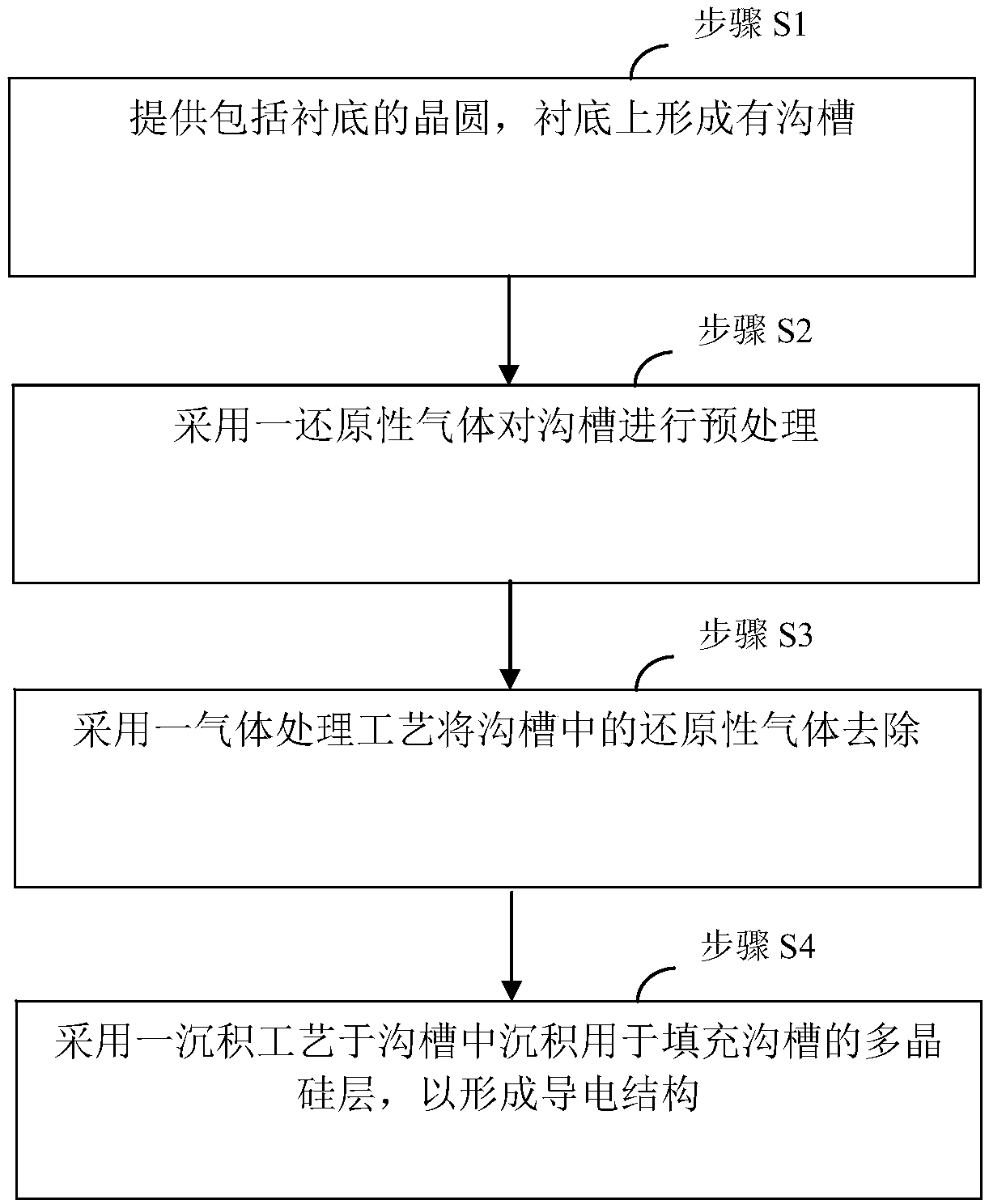

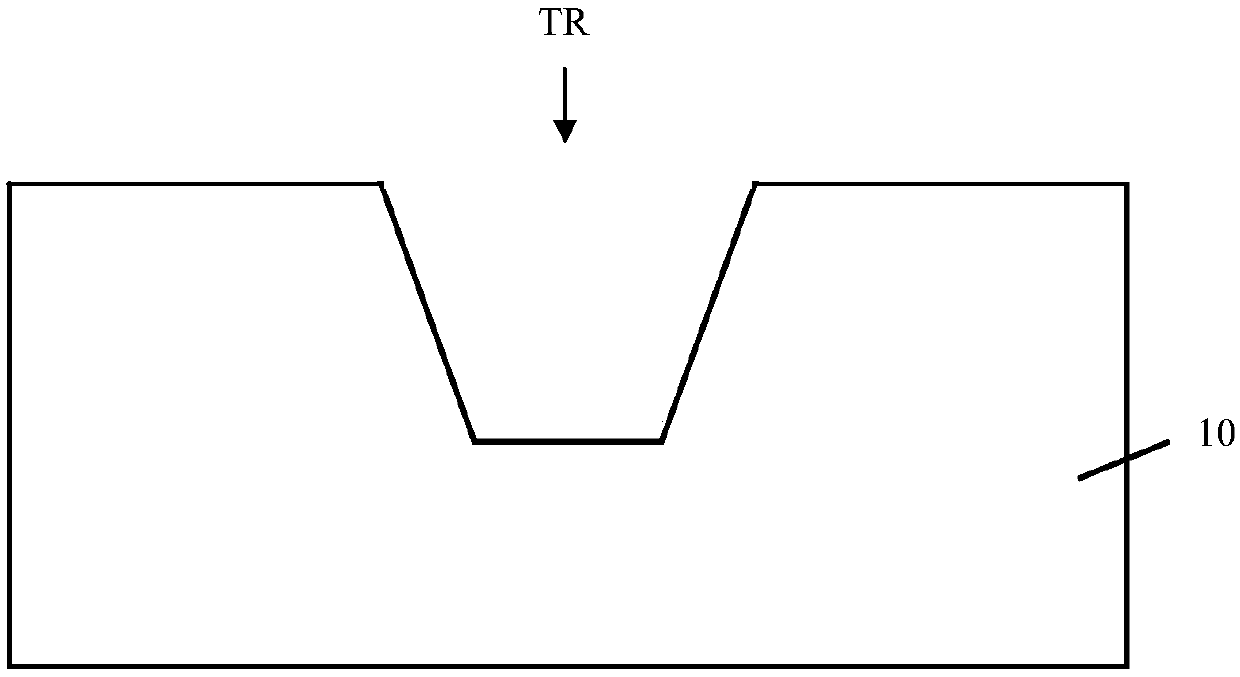

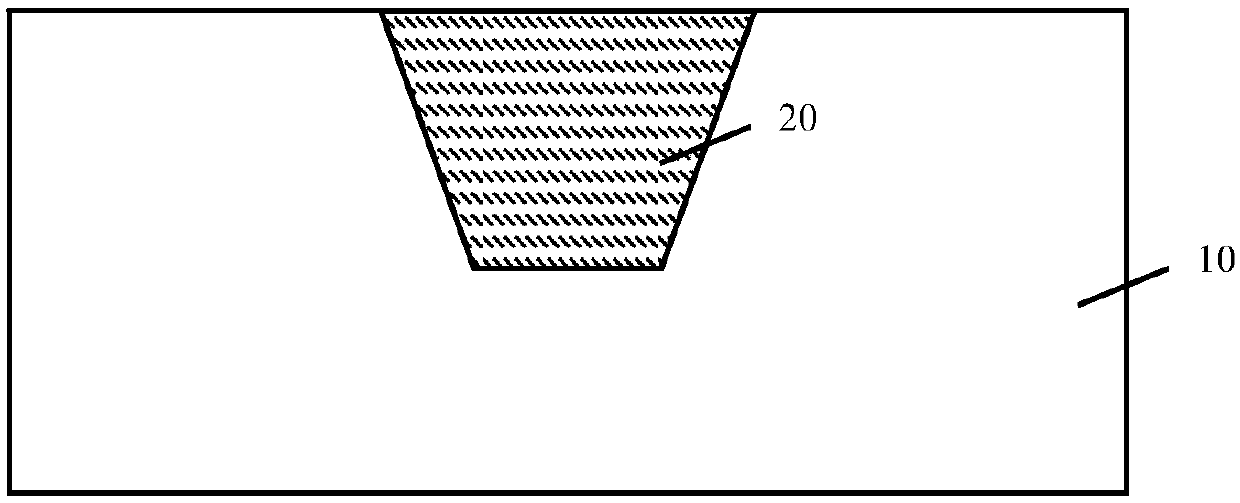

[0025] In a preferred embodiment, such as figure 1 As shown, a method for forming a conductive structure is proposed, and the formed structure can be as Figure 2~3 As shown, which can include:

[0026] Step S1, providing a wafer including a substrate 10 on which a trench TR is formed;

[0027] Step S2, pretreating the trench TR with a reducing gas;

[0028] Step S3, using a gas treatment process to remove the reducing gas in the trench TR;

[0029] Step S4, using a deposition process to deposit a polysilicon layer 20 for filling the trench TR in the trench TR to form a conductive structure.

[0030] In the above technical solution, the formed conductive structure may be a contact hole structure that electrically connects the top and bottom; other conventional structures for forming conductive structures may also be formed in the substrate 10 and in the trench TR, such as in t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com