Automatic oil dripping and lubricating device for steel wire rope

A technology of dripping oil lubrication and steel wire rope, which is applied in the field of steel wire rope, can solve the problems that the dust on the surface of the steel wire rope cannot be cleaned, the wire rope outlet guide work cannot be realized, and the lubricating device does not have a cleaning mechanism, etc., to achieve reasonable structure, improve practical performance, and convenient operation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

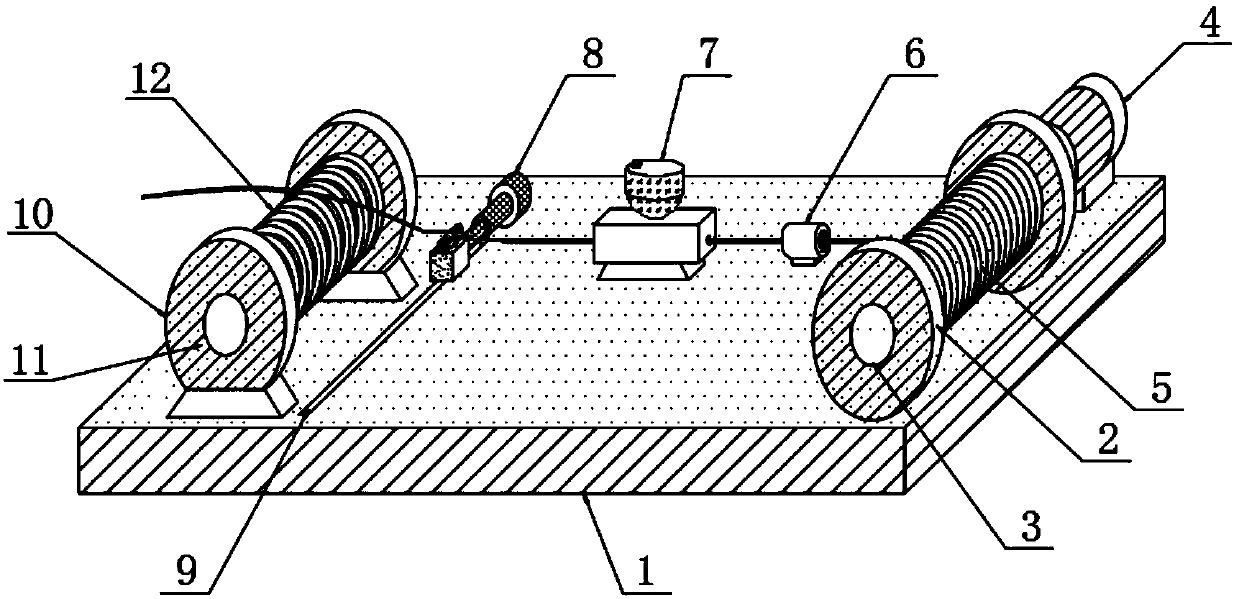

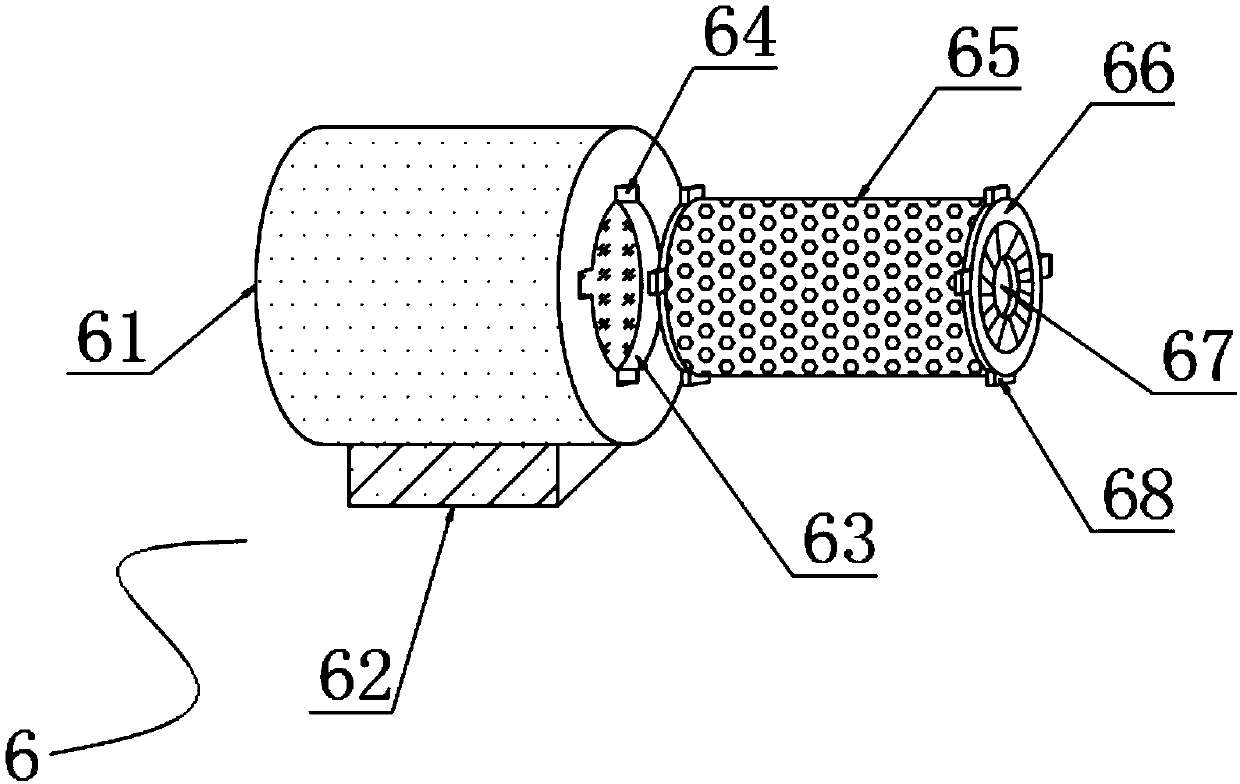

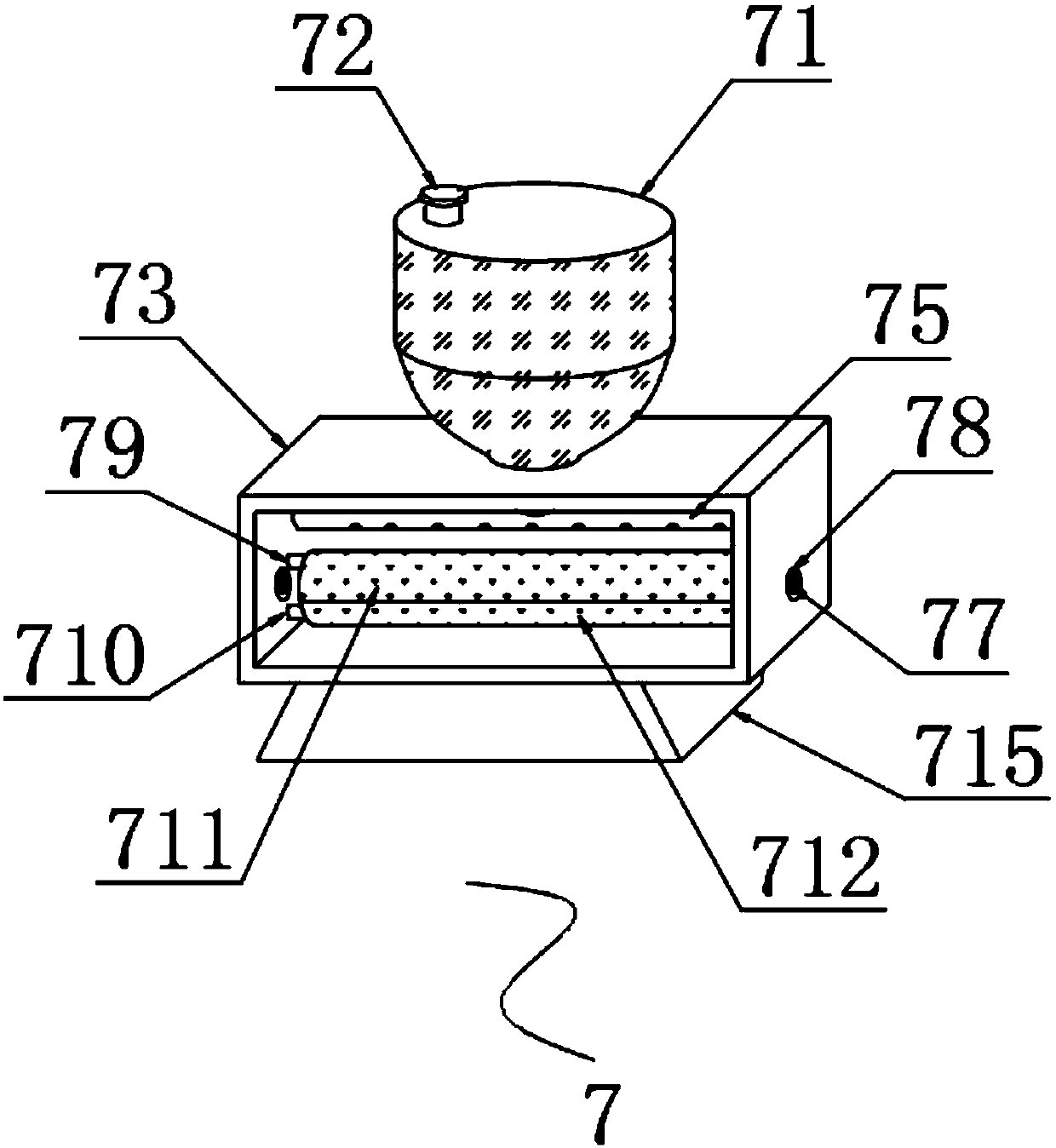

[0027] see Figure 1~6, in an embodiment of the present invention, an automatic drip lubrication device for steel wire ropes includes a workbench 1, a winding roller 2 is fixedly installed on one side of the upper surface of the workbench 1, and a winding roller 2 is installed inside the workbench 1 The rotating shaft 3, and the driving motor 4 (model YL80) is fixedly installed on the rear side of the winding roller 2. The set drive motor 4 works so that the rotating shaft 3 drives the winding roller 2 to rotate, so as to realize the wire rope 5 unwinding work. One side of the winding roller 2 is fixedly installed with a cleaning mechanism 6 at the position above the workbench 1, and the wire rope 5 passes through The cleaning mechanism 6 that is set realizes preliminary cleaning work, and the cleaning mechanism 6 includes a housing 61, the bottom of the housing 61 is fixedly equipped with a first base 62, and the inside of the housing 61 is provided with a cavity 63, and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com