A system and method for detecting appearance defects of chemical fiber tail

A technology for appearance defects and detection methods, applied in measuring devices, instruments, sorting, etc., can solve the problems of low production efficiency, high labor intensity, inaccurate detection, etc., and achieve the effect of cost saving and high-speed rejection.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

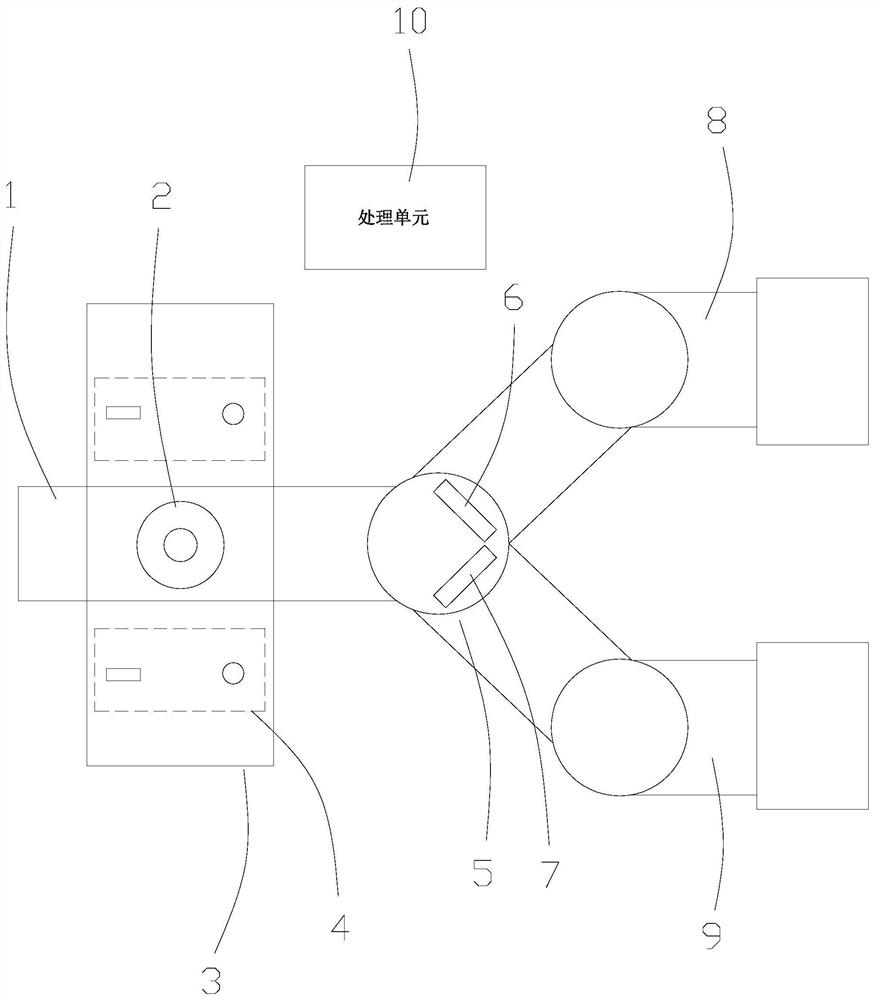

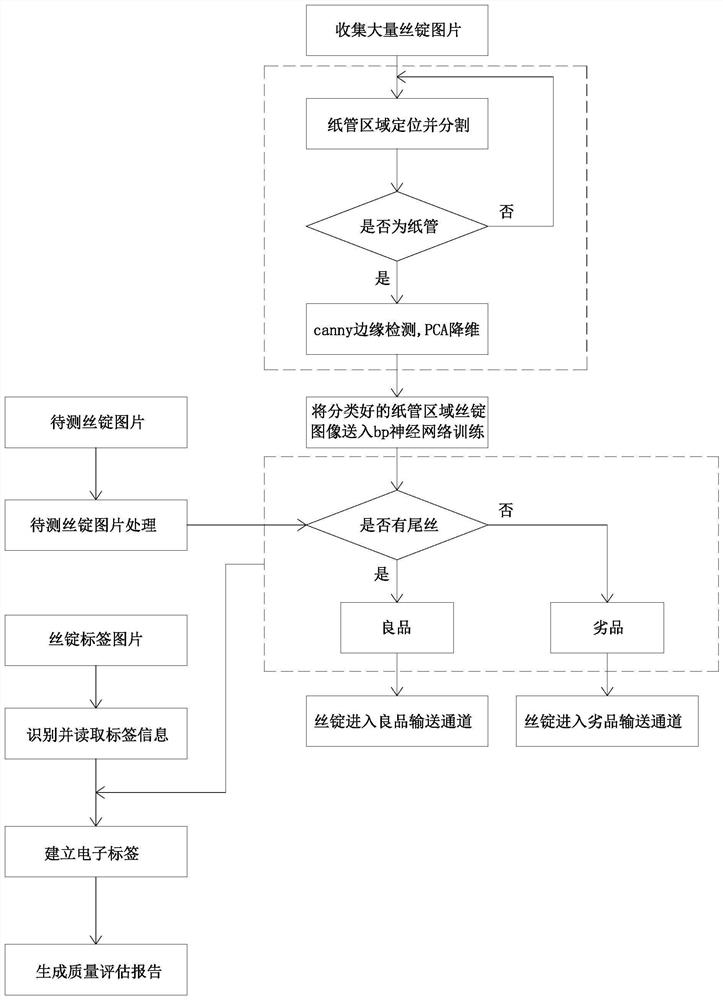

[0071] This embodiment is a system for detecting defects in the appearance of chemical fiber tails, such as figure 1 As shown, the system includes a tray 2 for loading silk spindles, a conveyor belt 3 for conveying the trays, labels are provided on the spindles, a dark box 3 is set on the transmission belt, and a sorting unit 5 is set on the transmission belt behind the dark box. An image acquisition unit 4 for collecting label images and silk spindle images is provided in it, and the image acquisition unit sends the collected information to the processing unit 10 for tail wire defect detection;

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com