An intelligent rubber scrap processing device

A processing device and technology of intelligent rubber, applied in the field of automation, can solve the problems of difficult recycling, no compaction treatment, scattered rubber scraps, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

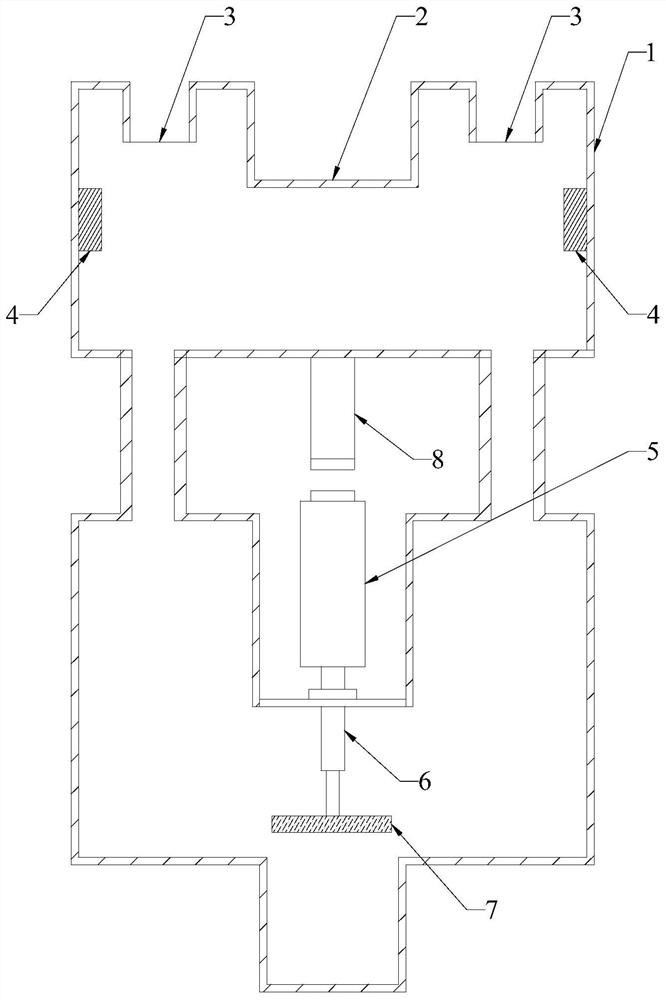

[0037] Please refer to figure 1 , Embodiment 1 of the present invention is:

[0038] An intelligent rubber waste processing device is characterized in that it includes a strip-shaped hollow shell 1, and the hollow shell 1 includes an adsorption section, a trigger section, and a collection section connected in sequence;

[0039] One end of the adsorption section is that the outer wall of one end of the hollow housing 1 has an integrally formed accommodation groove 2, the shape of the accommodation groove 2 is adapted to the shape of the rubber, and the hollow housing 1 One end of the hollow housing 1 is provided with two suction openings 3 respectively located on opposite sides of the housing groove 2, and a first metal coil 4 is provided inside one end of the hollow shell 1, and the first metal coil 4 corresponds to the suction opening. 3 position settings;

[0040]The trigger section includes two elastic pipes and a metal top post 8, the two ends of the elastic pipe are con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com