A monitoring method of ice thickness based on interface temperature

A technology of ice coating thickness and surface temperature, applied in measurement devices, instruments, etc., can solve problems such as poor adaptability and complex sensor structure, and achieve the effect of simple data analysis method and long-term online monitoring.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

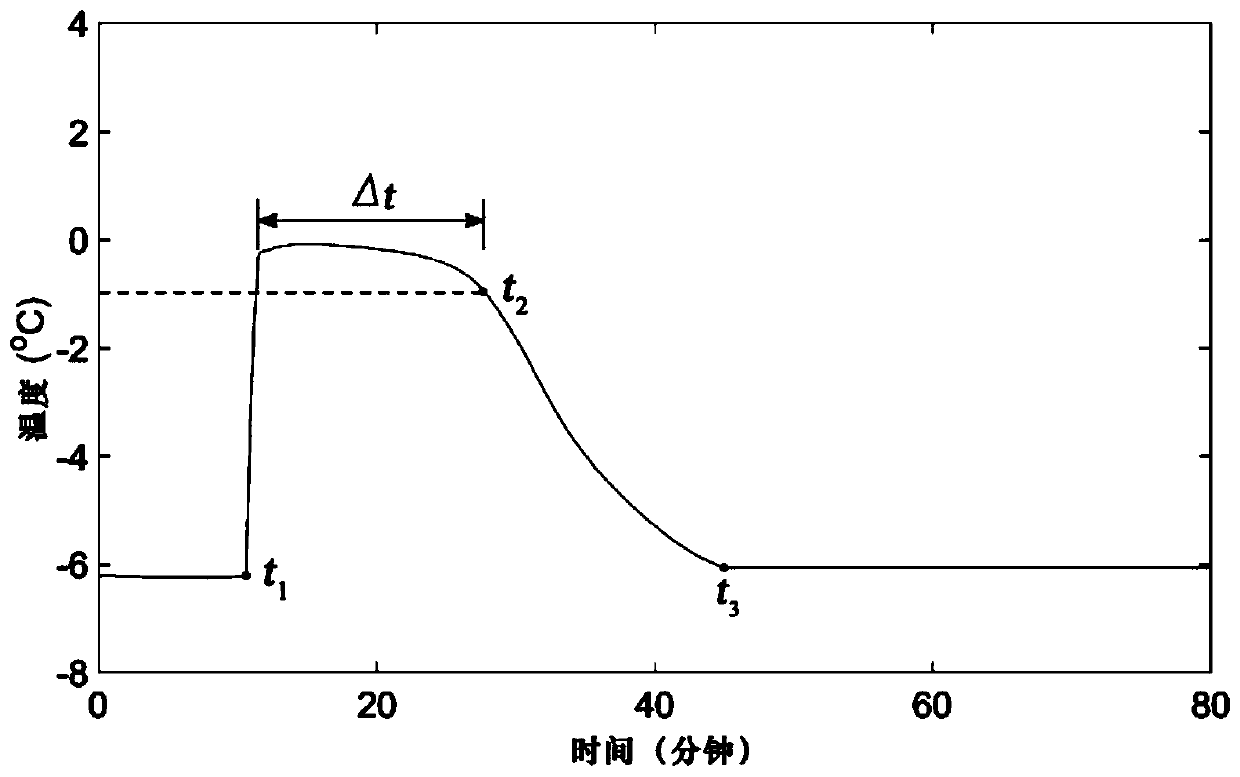

[0031] Icing on the surface of objects in nature is usually divided into two types: transparent ice and frost ice. Both types of ice are formed when supercooled water droplets impinge and attach to the surface of structures. In general, the temperature of the supercooled water droplets from the air is not consistent with the surface temperature of the structure, so when the supercooled water droplets hit the surface of the structure and form ice, it will involve complex energy conversion, heat exchange and heat balance processes, and then Affects the temperature of the surface of the structure. The energy conversion process, heat exchange process and influence on temperature mainly involved are as follows:

[0032] First, the supercooled water droplet attaches to the surface of the structure for the first time, heat conduction occurs immediately between the supercooled water droplet and the surface of the structure, and the temperature of the surface of the structure changes ...

specific Embodiment approach 2

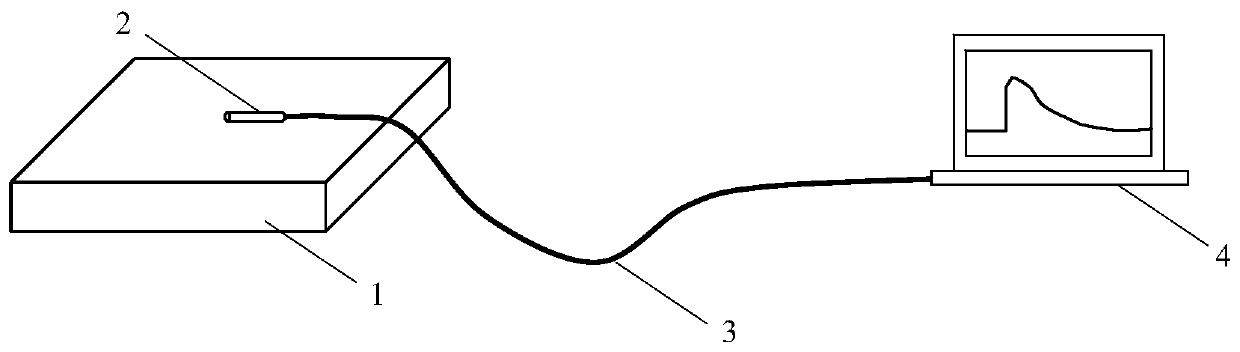

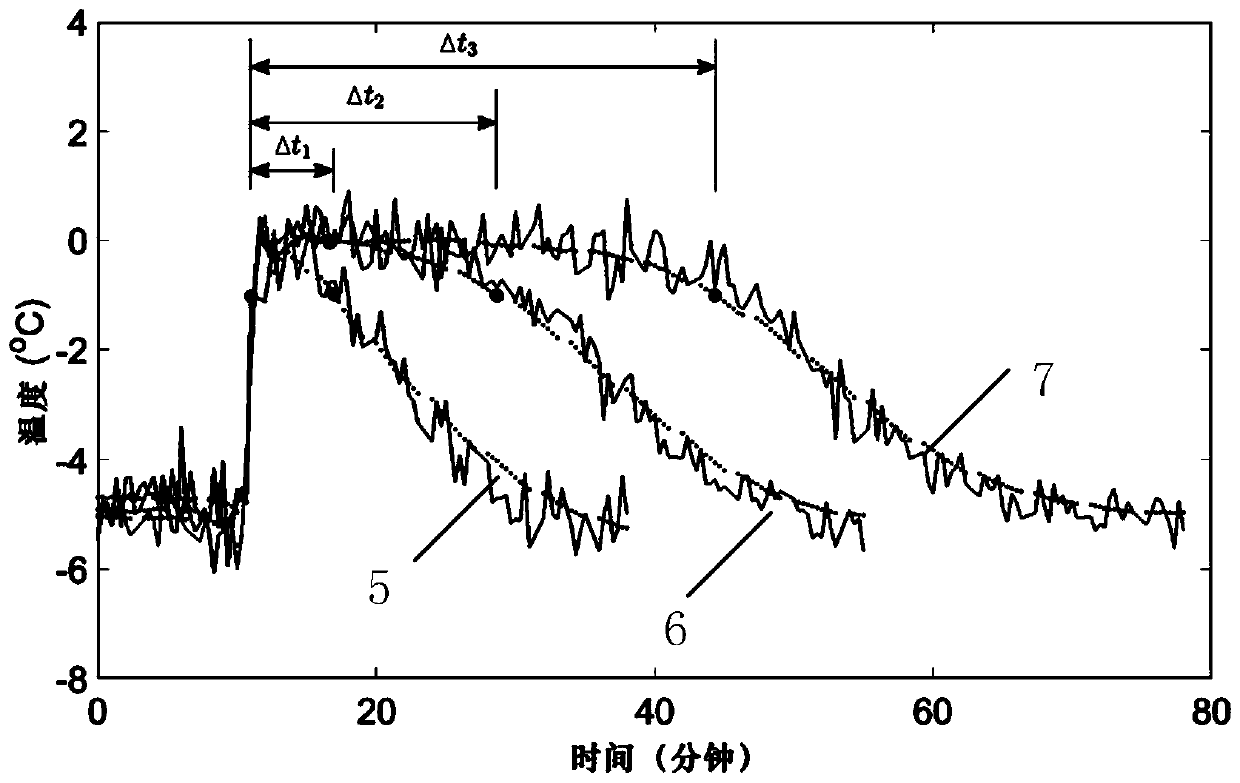

[0062] When there is no ice on the surface of the structure, the measured temperature curve is the surface temperature of the structure, which is basically consistent with the ambient temperature. When weather phenomena such as freezing rain occur, supercooled water hits and adheres to the surface of the structure, which will cause the temperature to rise in a short time. exist image 3 The test shown (the surface icing test of FRP material) simulates the icing process in a cryogenic laboratory using a supercooled water spray method. When icing starts, the temperature rises rapidly and then falls slowly, with -1 degree Celsius as the threshold, the characteristic duration Δt is obtained 1 Used to estimate ice coverage. Further, the spraying time is longer, and the amount of ice is more, and the characteristic duration Δt is obtained 2 and Δt 3 . In the experiment, because the thickness of the ice coating is uniform, take out a small piece of ice and use a vernier caliper ...

specific Embodiment approach 3

[0066] Same as the test in the second embodiment, the influence of the ambient temperature on the characteristic duration is given in this embodiment, such as Figure 5 shown. Curve 8 in the figure corresponds to an ambient temperature of minus 8 degrees Celsius, and curve 9 corresponds to an ambient temperature of minus 5 degrees Celsius. It can be seen from the figure that the ambient temperature has little influence on the characteristic duration.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com