Spring load simulation device with adjustable load

A simulation device, spring load technology, applied in the field of spring load simulation device, can solve the problems of high price, high maintenance cost, etc., and achieve the effect of simple structure, easy production and installation, and easy purchase

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be described in detail below with reference to the accompanying drawings and examples.

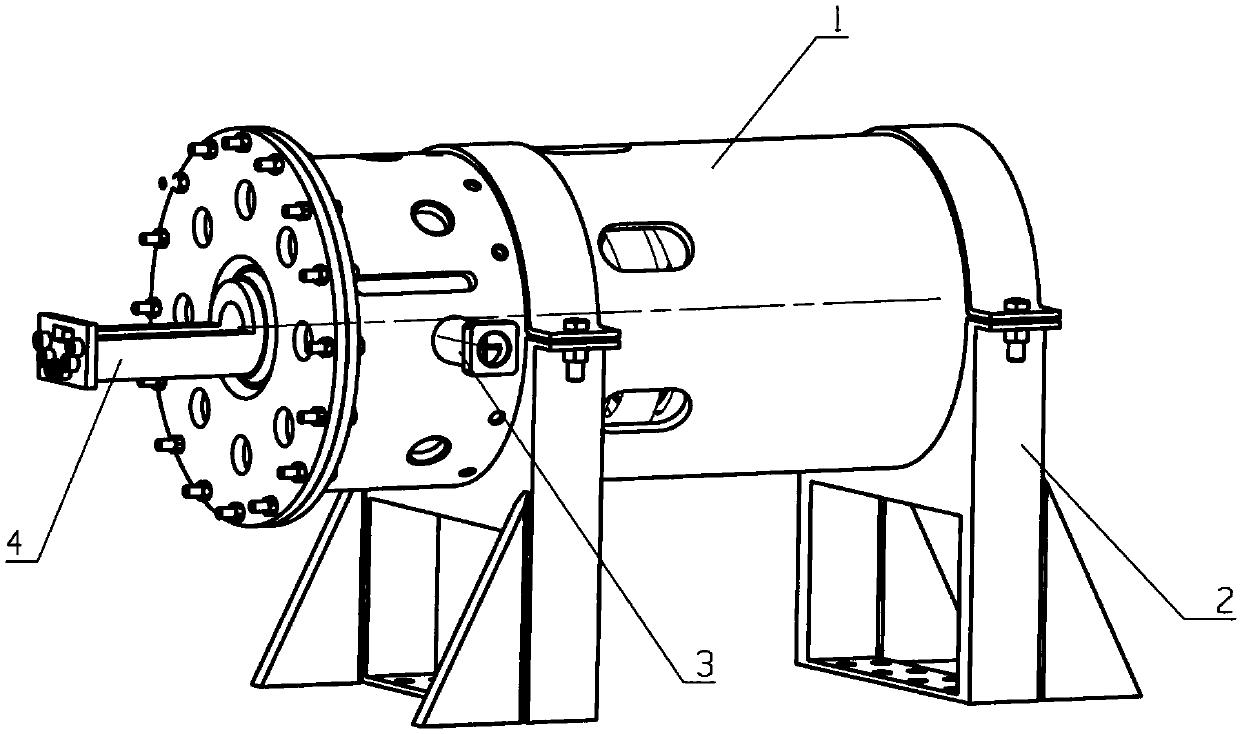

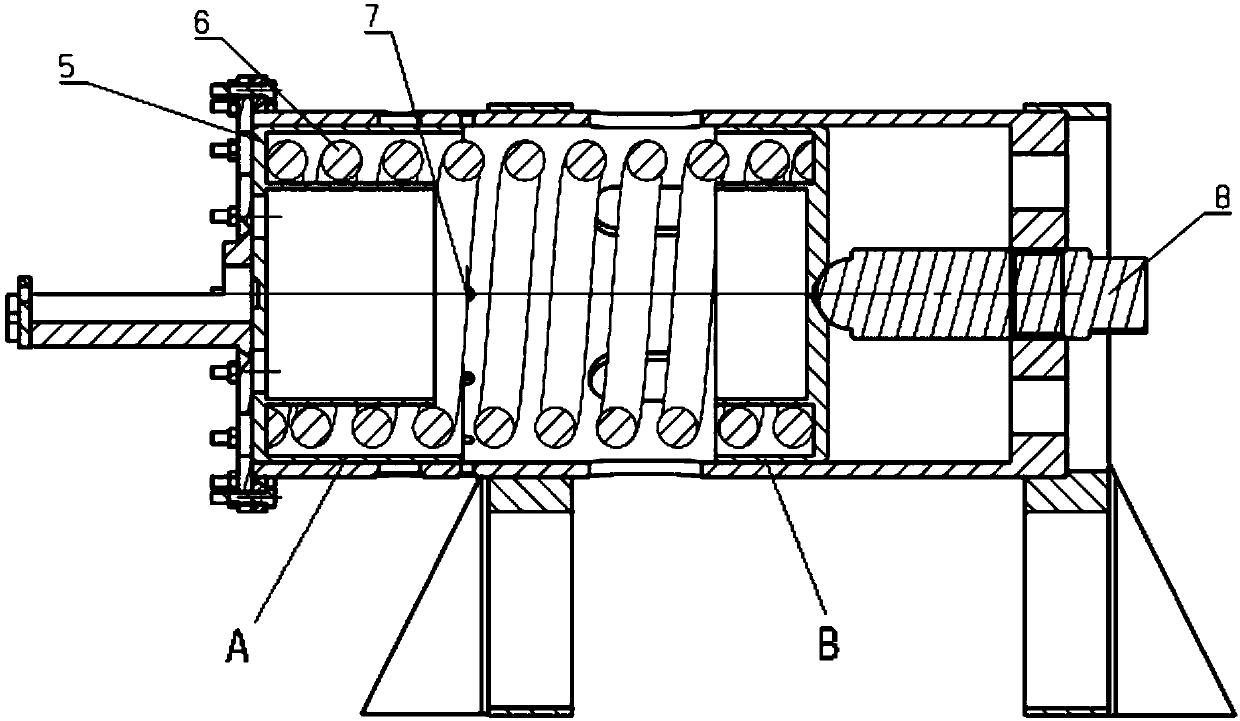

[0024] This embodiment provides a spring load simulation device with adjustable load, see the attached figure 1 and figure 2 , including: load spring 6, outer shell 1, support 2, shear pin 7, locking pin 3, mounting seat 4, spring sleeve 5 and limit rod 8;

[0025] The outer casing 1 is a cylindrical structure with both ends closed, and one end is processed with a through hole, and the other end is processed with a threaded hole, and a limit rod 8 is installed in the threaded hole; the outer casing 1 is supported by a support 2 installed at the bottom on the support plane;

[0026] The load spring 6 is installed in the outer shell 1 through two spring sleeves 5 sleeved at its two ends, wherein one end of the spring sleeve 5 is open and the other end is closed, and an annular groove coaxial with it is processed at the open end. The end of loading spring...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com