Large-volume dose adhesives preparation and real-time monitor

A real-time monitoring, large-volume technology, applied in various fluid ratio control, mixers, chemical instruments and methods, etc., can solve problems such as low efficiency, difficult to respond quickly, insufficient, etc., to achieve safe operation of equipment and easy control Adjusting and avoiding the effect of work interruption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

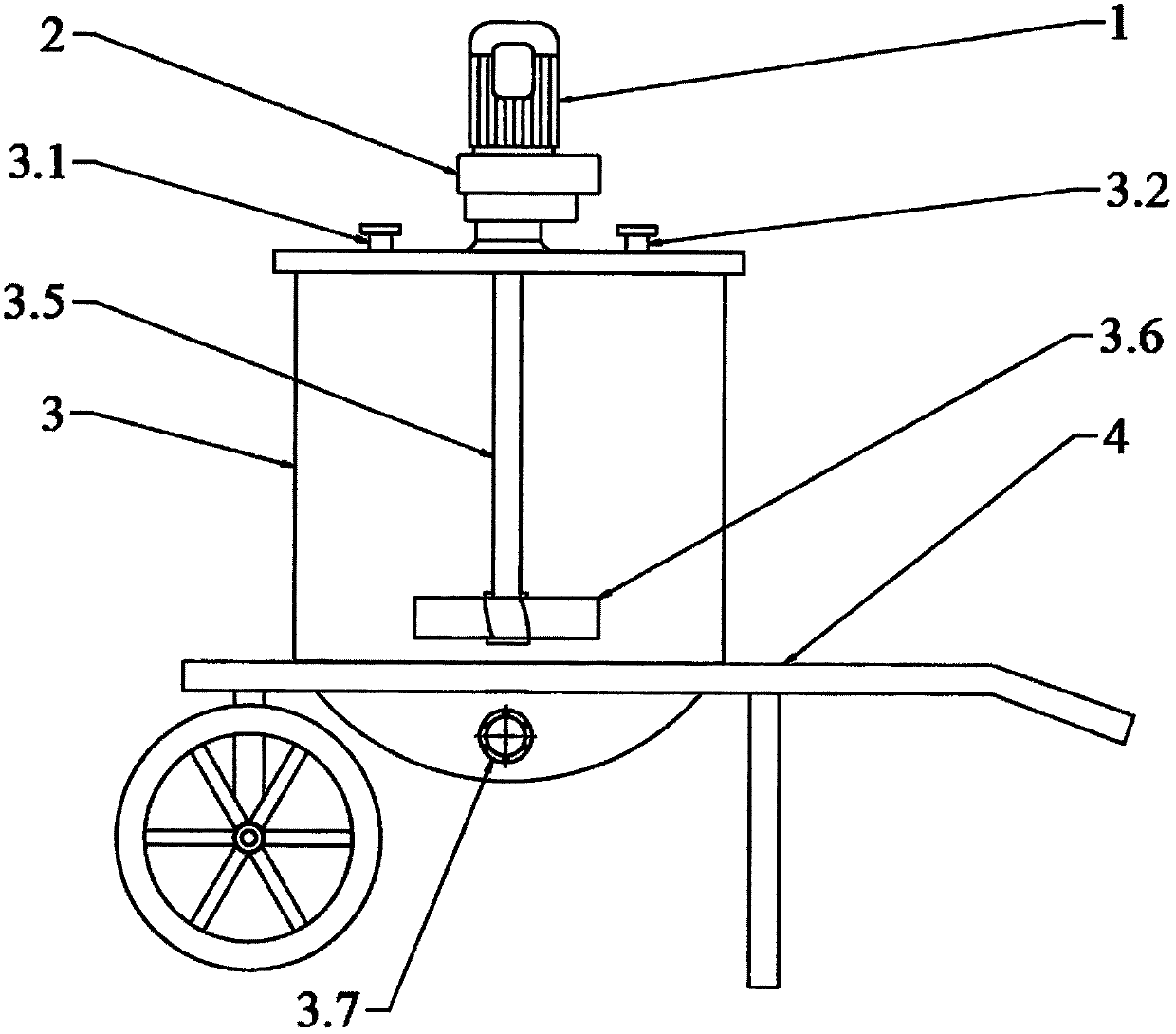

[0021] Such as figure 1 As shown, the present invention is a large-volume adhesive preparation and real-time monitoring instrument, including a motor 1, a frequency converter 2, a mixing tank 3, a supporting frame 4, a controller 5 and a sensor probe 6. The motor 1 is fixed directly above the mixing tank 3; the frequency converter 2 is installed below the motor 1; the sensor probe 6 is installed on the inner wall of the mixing tank 3; the sensor probe 6 is connected with the controller 5, and the controller 5 is fixed on the outer wall of the mixing tank 3 ; The mixing bucket 3 is fixed on the support frame 4 .

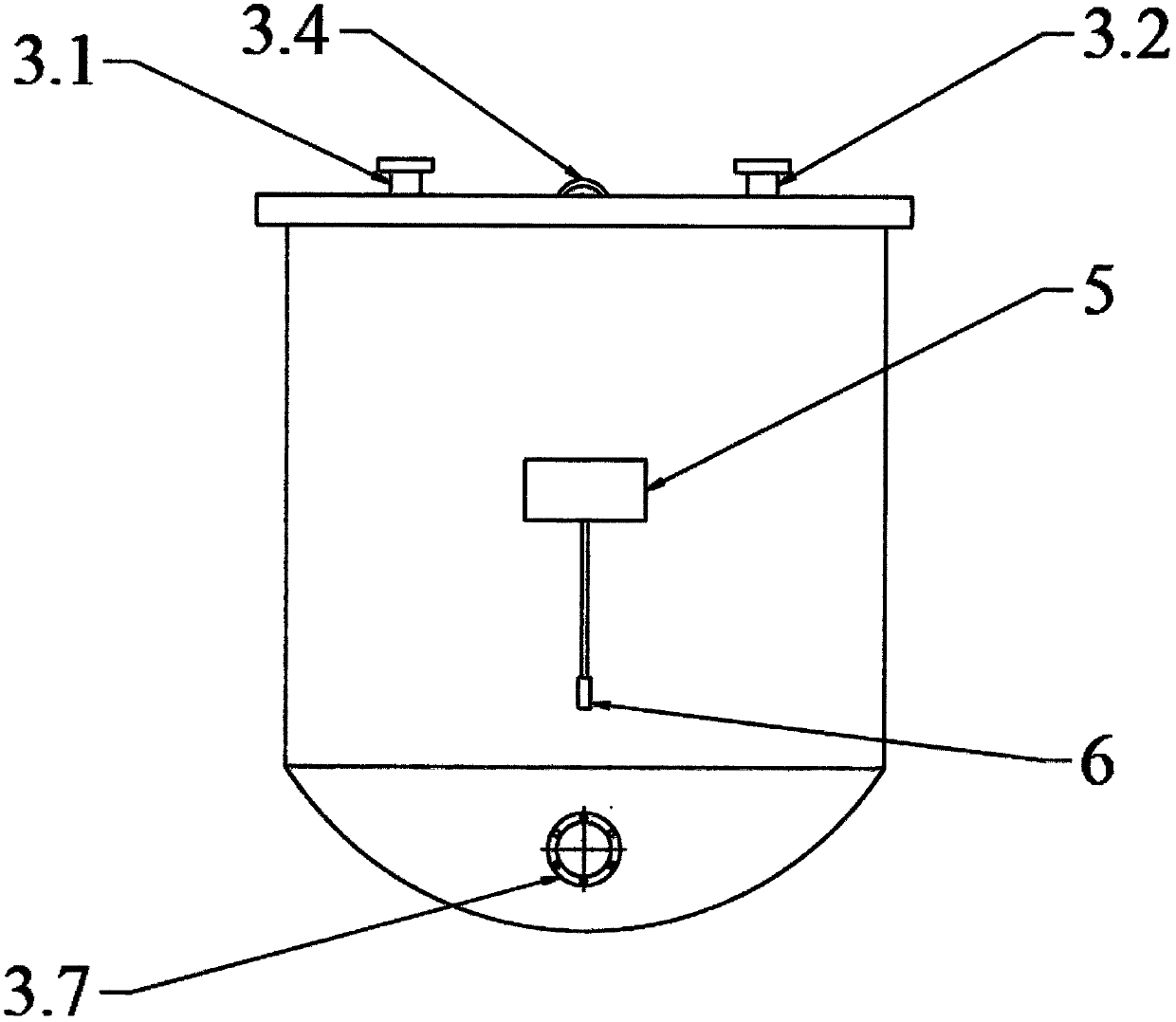

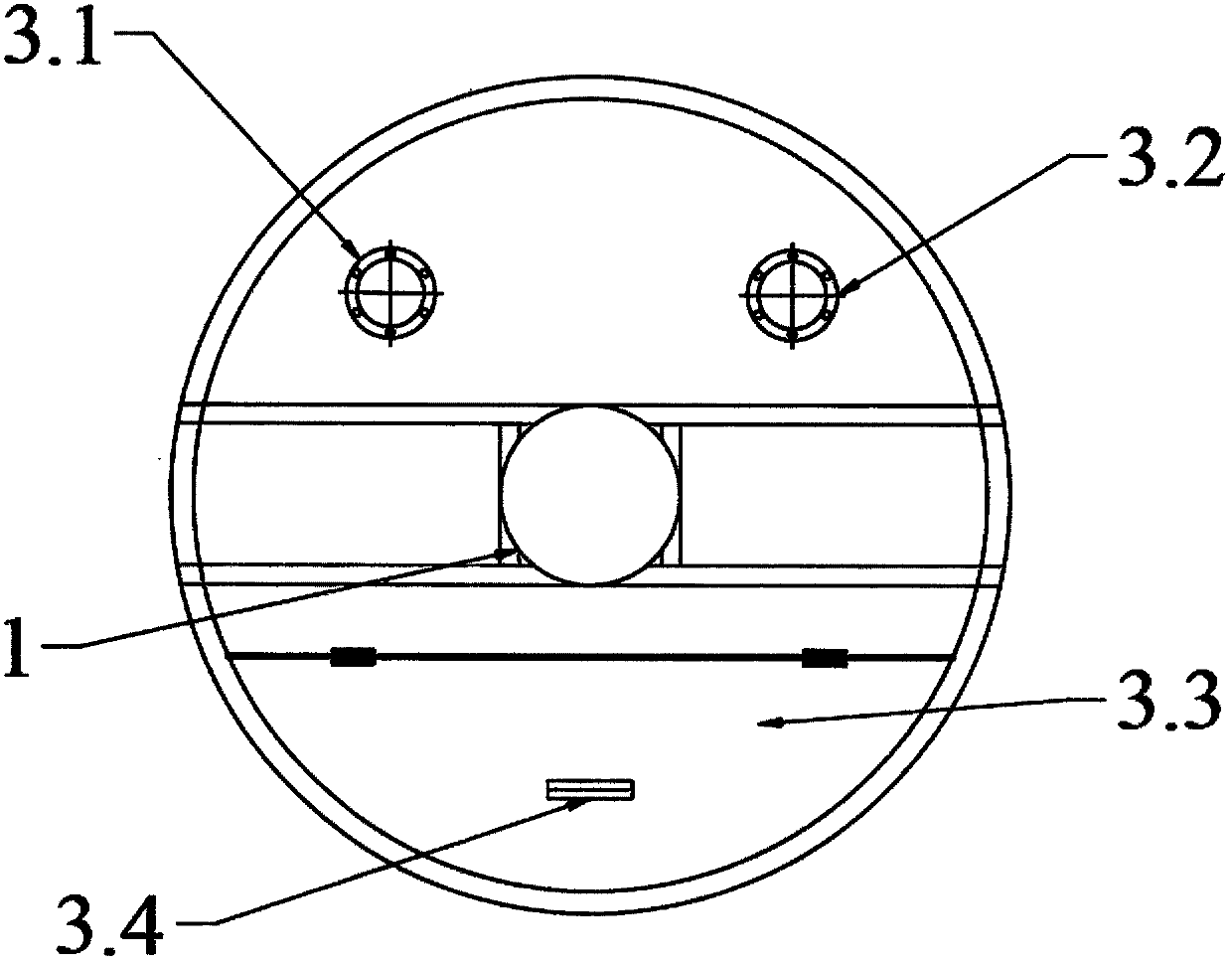

[0022] Such as figure 2 As shown, the mixing tank 3 is provided with an A feed port 3.1, a B feed port 3.2, a cover plate 3.3, a cover plate handle 3.4, a stirring shaft 3.5, a stirring paddle 3.6 and a discharge port 3.7. The A feeding port 3.1 and the B feeding port 3.2 are arranged on the upper end surface of the mixing tank 3; the upper end surface of the mixin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com