Steam generator with adjustable pressure and temperature

A steam generator and pressure-adjustable technology, used in steam generation, lighting and heating equipment, control systems, etc., can solve the difficulty in regulating the pressure and temperature of superheated steam, the low working pressure of the system, and the difficulty in controlling and regulating steam pressure. And other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

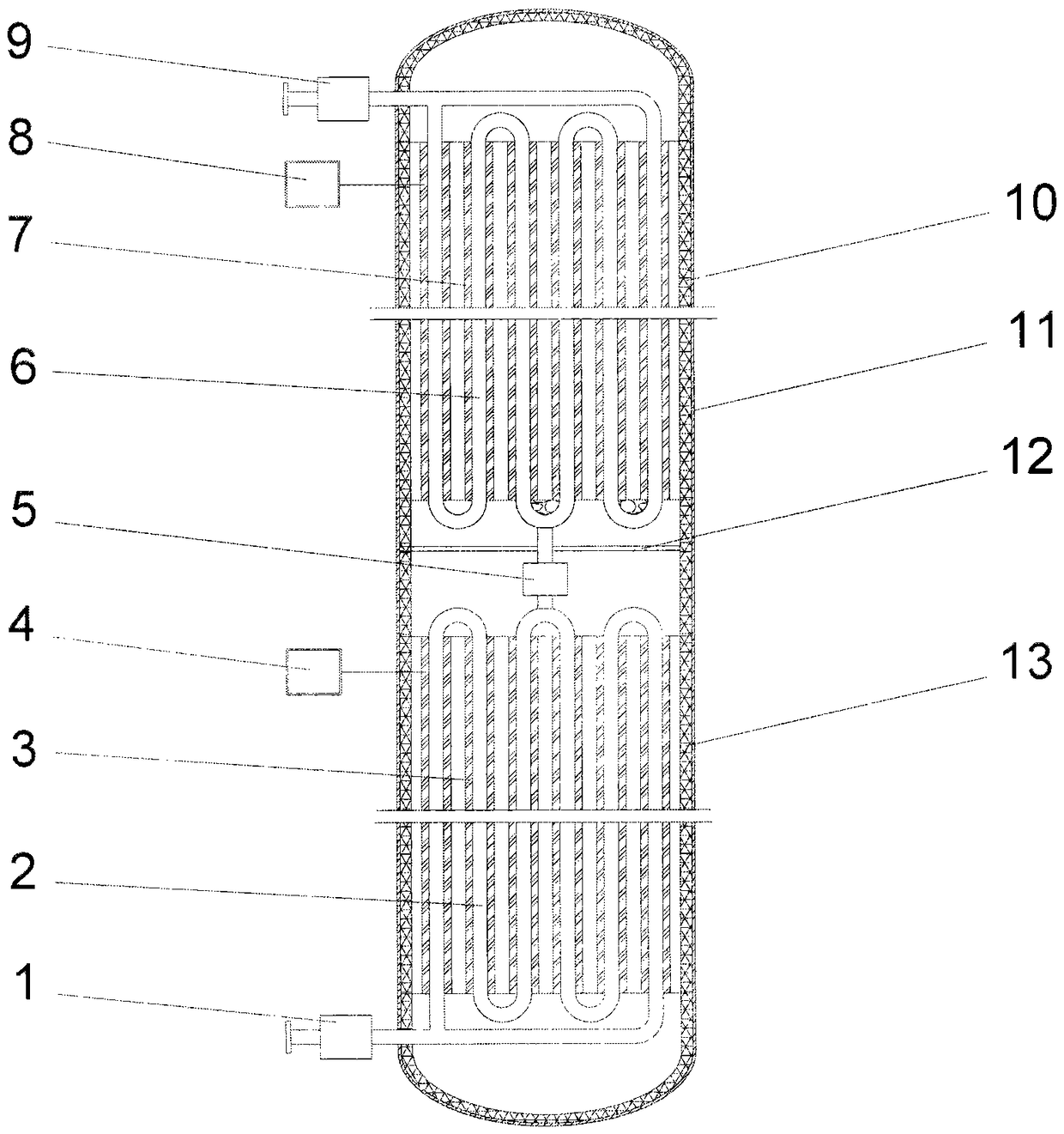

[0015] The steam generator with adjustable pressure and temperature provided by the present invention is composed of a steam generator heat pipe (2), a throttle pressure regulating valve (5), a superheater heat pipe (6), and a water inlet control valve (1). ), a steam generating section power regulator (4), a steam superheating section power regulator (8) and a superheated steam outlet regulating valve (9), characterized in that: the throttling pressure regulating valve (5) is in the steam generator heat taking pipe (2) Between the superheater heat pipe (6), the superheater heat pipe (6) is located behind the throttle and pressure regulating valve (5), and a steam generation section insulation layer ( 13), a steam superheating section insulation layer (10) is arranged on the inner surface of the casing (11) of the steam superheating section, and the steam generating section and the steam superheating section are separated by a partition plate (12).

[0016] refer to figure 1 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com