Automatic circular wafer rewinding mechanism

A silicon wafer rewinding technology, which is applied in the field of automatic circular silicon wafer rewinding mechanism, can solve the problems of high error rate in manual work and the need for special personnel to operate, so as to achieve stable and efficient output, avoid metal contamination, and avoid metal contamination. pollution effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

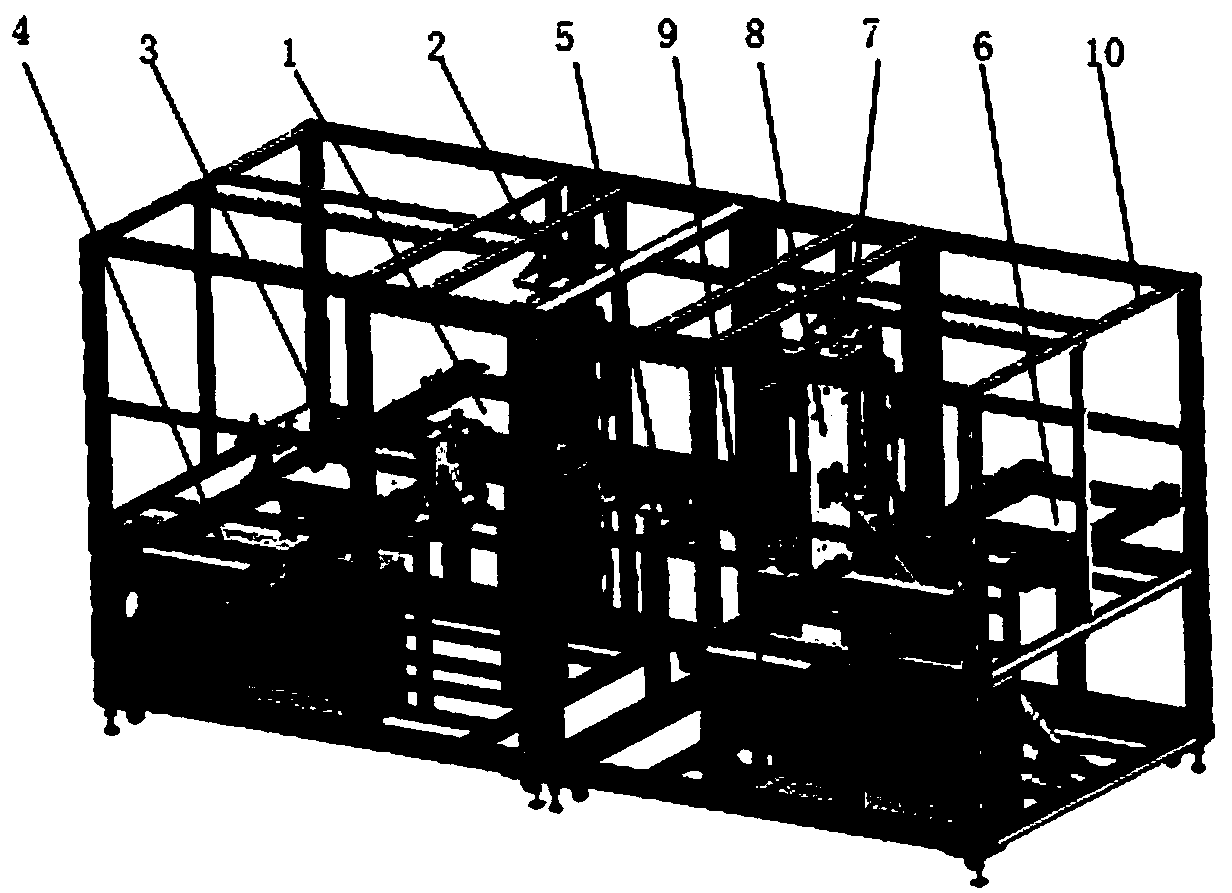

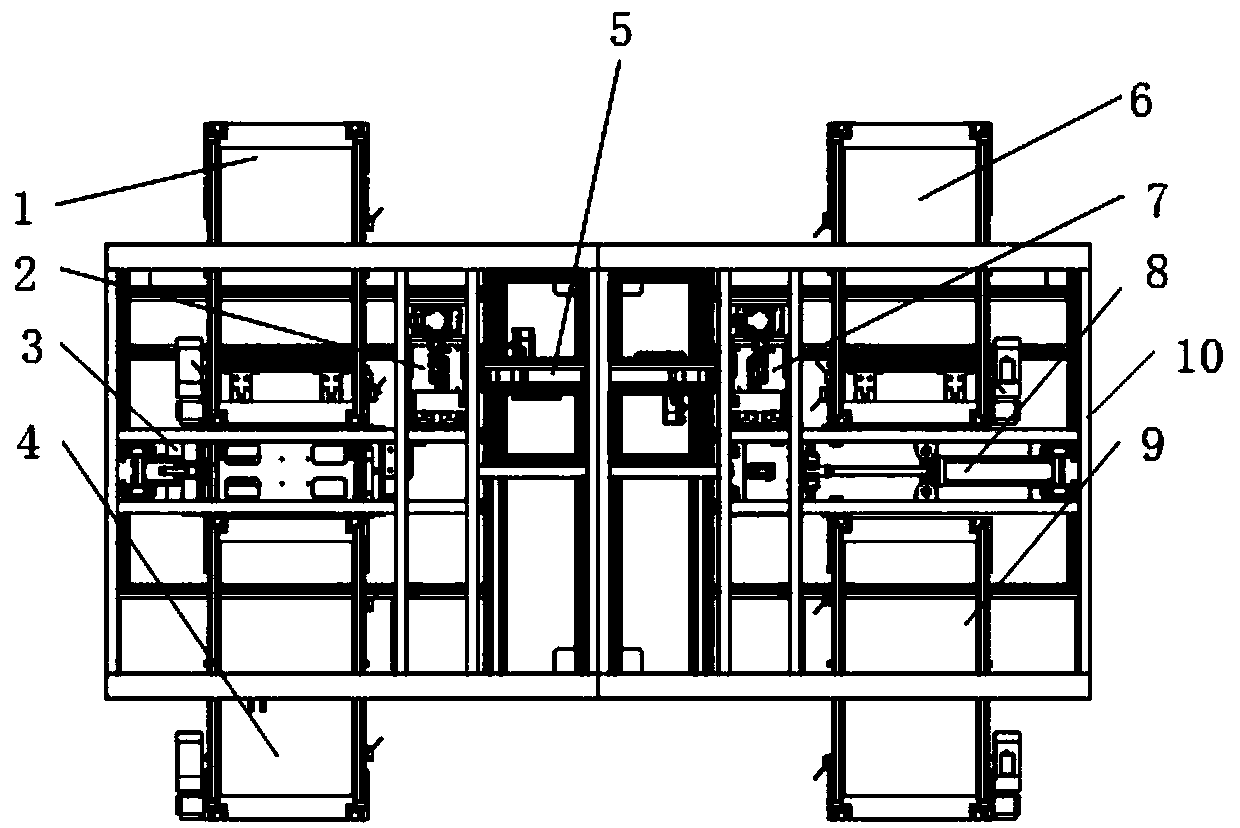

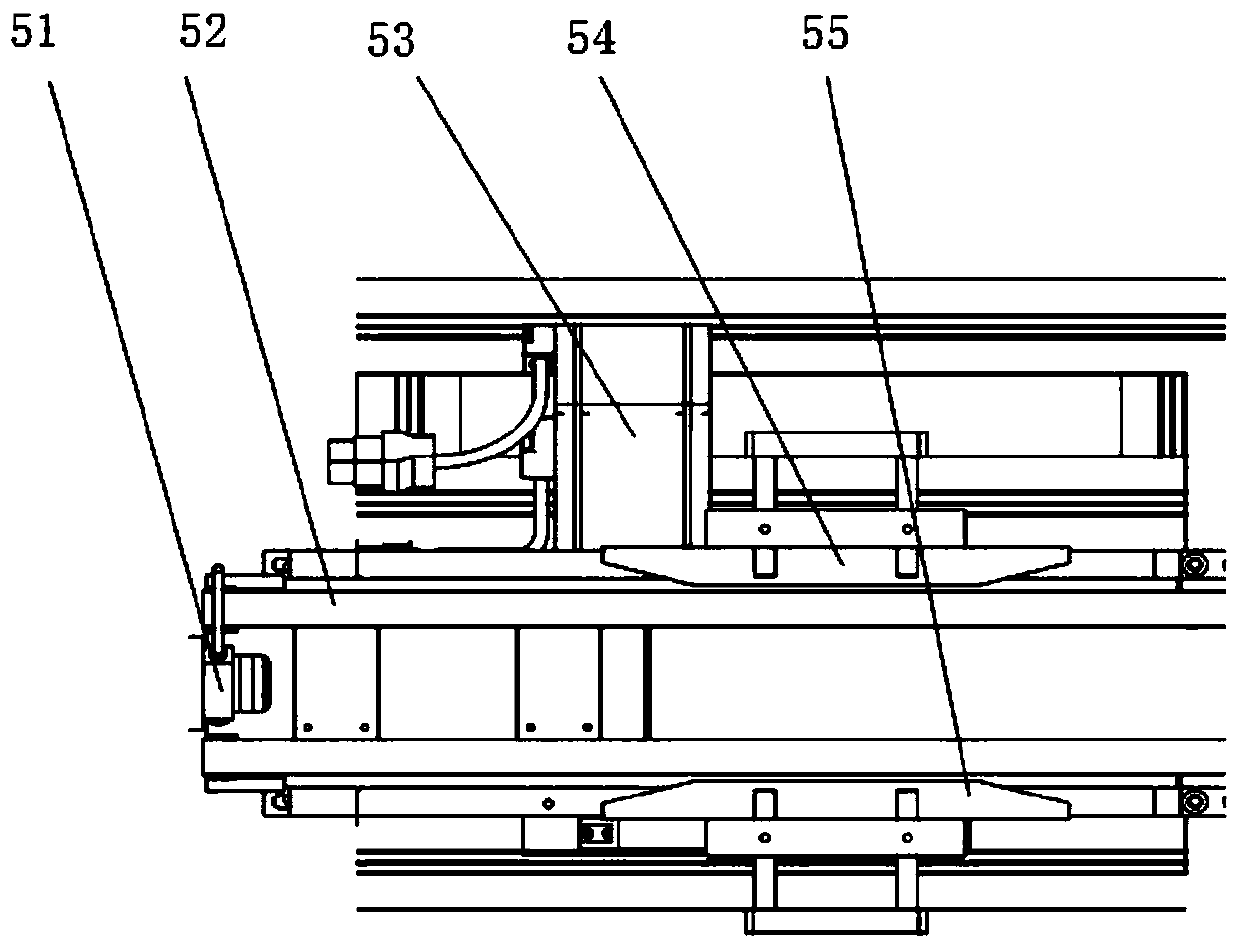

[0032] Such as Figure 1-3 As shown, this example is an automatic circular wafer rewinding mechanism, which is used in an automatic circular wafer rewinding machine. Reference Figure 1-2 , The automatic circular wafer rewinding machine includes a frame 10, a first processing room and a second processing room. The first processing room and the second processing room are relatively isolated. The first processing room is a clean area, and the second processing room is In the metal area, a film rewinding mechanism 5 is arranged in the middle of the frame 10. The film rewinding mechanism 5 includes a first film rewinding part and a second film rewinding part. A rewinding part is arranged in the first processing chamber, and the second rewinding part is arranged in the second processing chamber. reference image 3 Among them, the rewinding part includes: a transmission device 52, a sensor, a transmission drive device 53 and a positioning block. The transmission device 52 can be sele...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com