Powder coating mixing device

A mixing device and powder coating technology, applied in the direction of mixer, transportation and packaging, dissolution, etc., can solve the problem of not realizing the integration of coating material and coating, and achieve the goal of reducing measurement steps, ensuring accuracy, and reducing human operations Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The following is further described in detail through specific implementation methods:

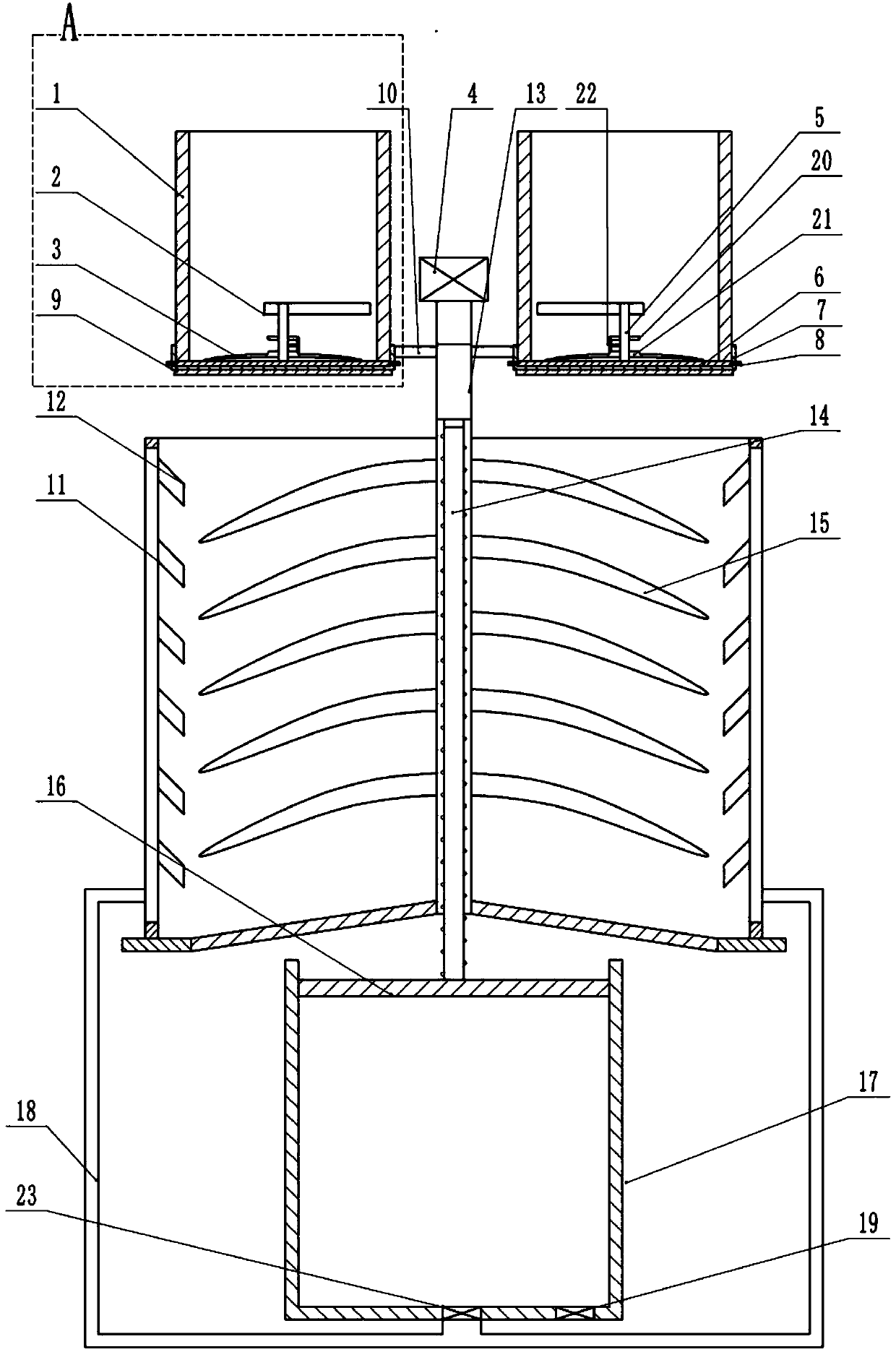

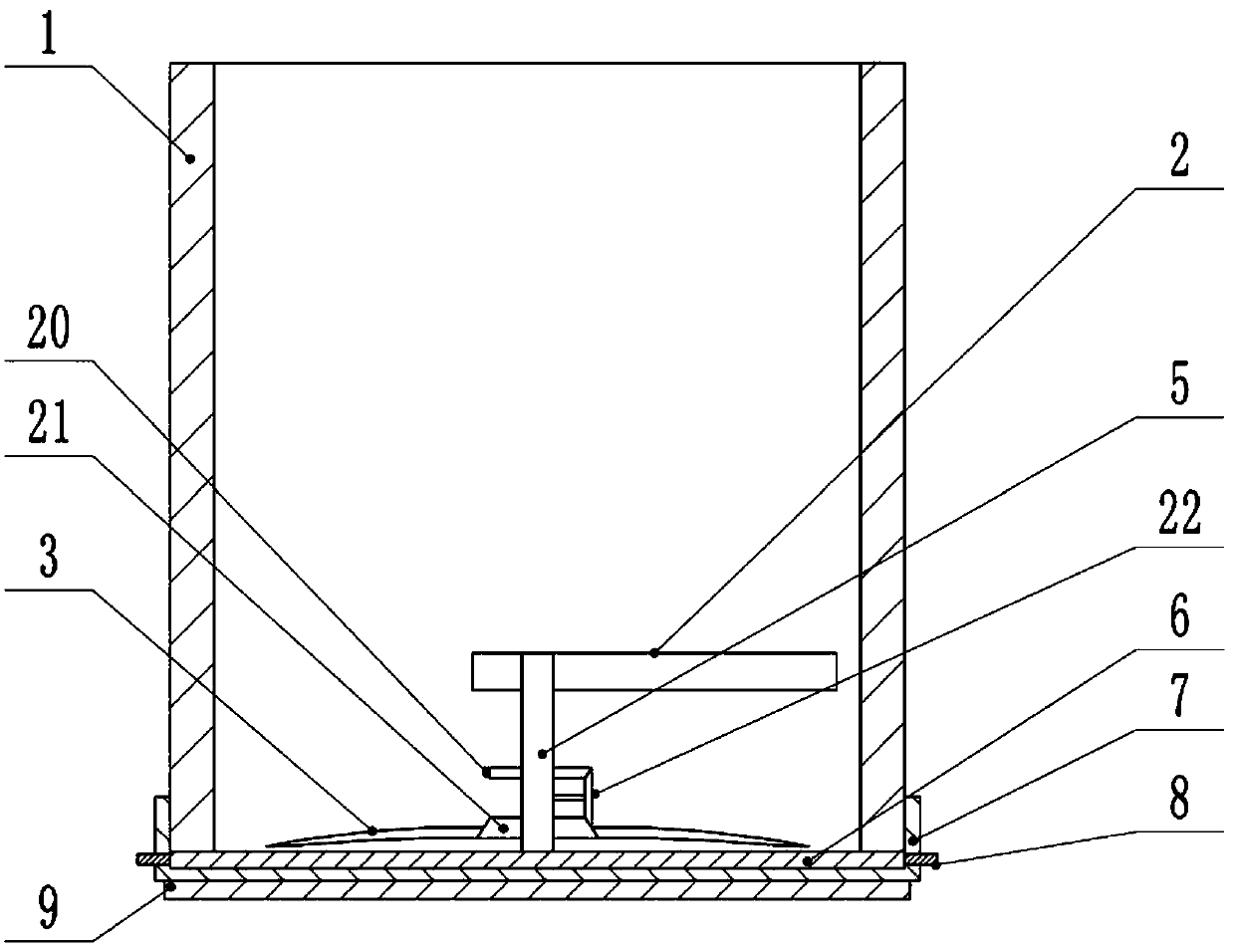

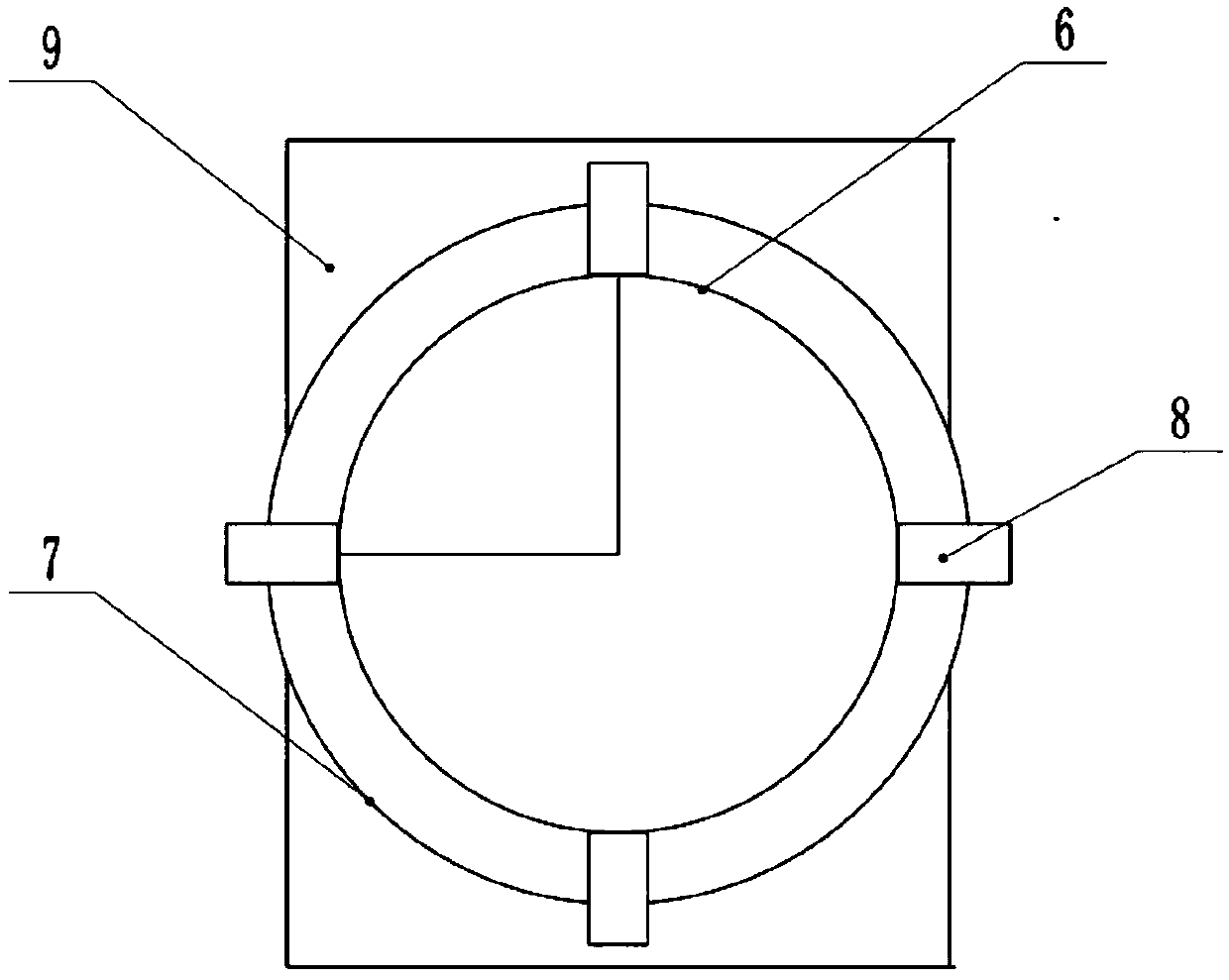

[0025] The reference signs in the accompanying drawings of the description include: leaking bucket 1, rolling ball 2, rotating blade 3, motor 4, third vertical rod 5, first leaking plate 6, second leaking plate 7, screw 8, The first baffle plate 9, the gear 10, the mixing box 11, the nozzle 12, the first vertical rod 13, the second vertical rod 14, the stirring blade 15, the slide plate 16, the piston barrel 17, the pipeline 18, the air inlet valve 19, the first A bevel gear 20, a second bevel gear 21, a third bevel gear 22, and an air outlet valve 23.

[0026] The embodiment is basically as attached Figure 1-3 Shown: a powder coating mixing device, including a frame, a motor 4, a leakage unit and a mixing and stirring unit, the leakage unit includes a number of leakage buckets 1 fixed on the frame, and the upper surface of each leakage bucket 1 and the bottom surface are all open...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com