Automatic glue charging system and automatic glue dipping equipment

An automatic, dipping technology, applied in the direction of coating, surface coating liquid devices, etc., can solve the problems of large fluctuations in the liquid level of the production glue tank, affect production efficiency, increase the failure rate, etc., and achieve stable dipping liquid level , high production efficiency and low bubble generation rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

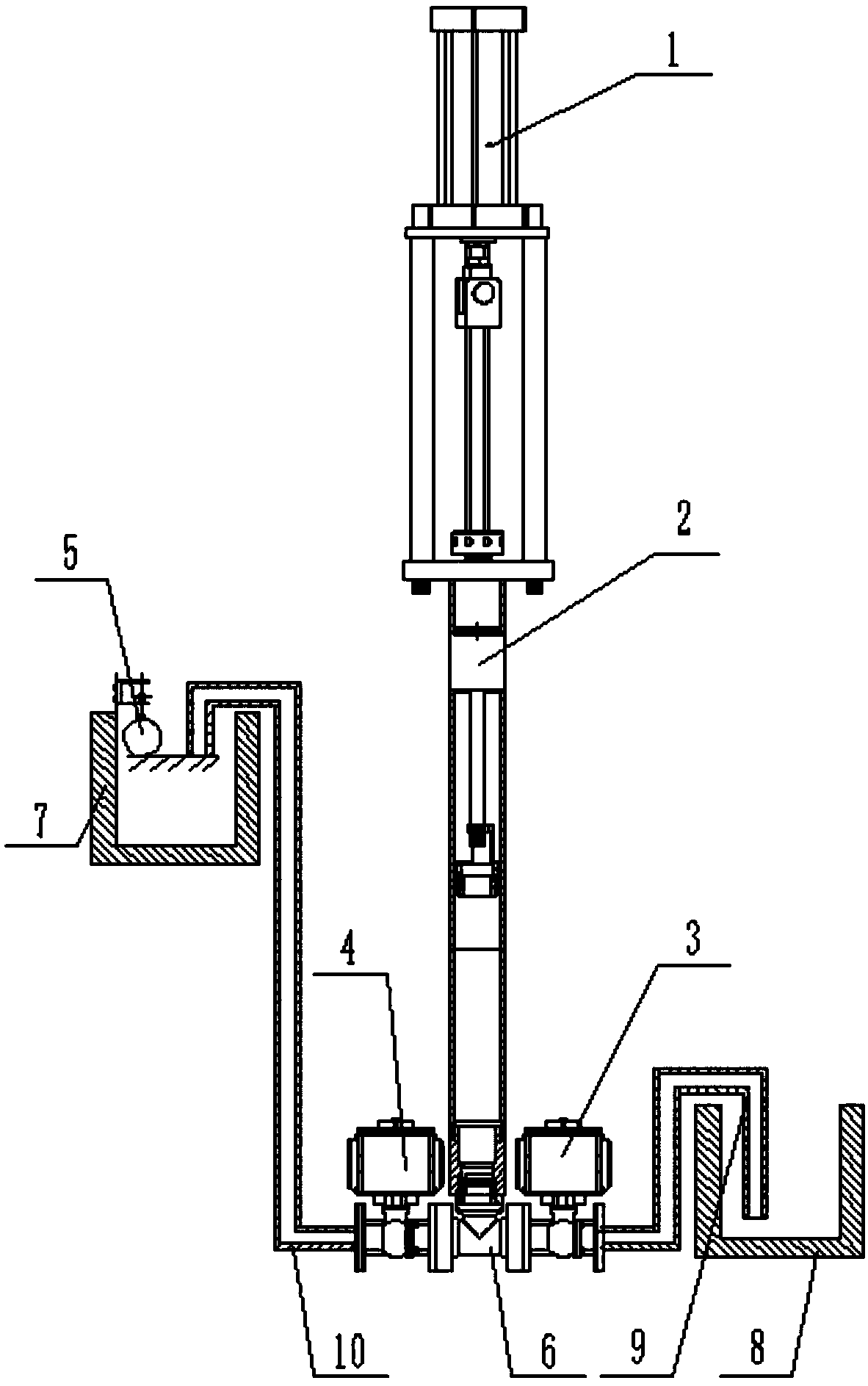

[0034] Such as figure 1 As shown, the automatic glue adding system includes a suction pipe 9, a pressure pipe 10, a first valve 3, a second valve 4, and a vacuum system 2. The vacuum system 2 includes a vertical cylindrical inner cavity, and the piston fits into the inner cavity. The side wall reciprocates up and down along the inner cavity to adjust the volume of the inner cavity. The piston is driven by the power unit 1, which can be directly pushed and pulled, or can be driven by a screw thread, which is more stable and powerful.

[0035] Other methods can also be used, such as a fan-shaped inner cavity, and then the volume of the inner cavity can be adjusted by rotating a pressing plate with a radius length along the center of the circle.

[0036] The lower part of the inner cavity can be connected with a tee 6 , the tee 6 communicates with the suction pipe 9 through the first valve 3 , and the tee 6 also communicates with the pressure pipe 10 through the second valve 4 ....

Embodiment 2

[0047] As in Embodiment 1, a transparent observation window is provided on the cavity side wall of the vacuum system 2 . When there is a problem in the inner cavity, the second valve 4 is closed, the first valve 3 is opened, the piston is pressed to the lowest level, and the rubber material flows back to the discharge tank 8 or a separate recovery tank.

Embodiment 3

[0049] As in Example 1, the first valve 3 and the second valve 4 are one-way valves, the flow direction of the first valve 3 is that the suction pipe 9 flows to the inner cavity, and the flow direction of the second valve 4 is that the inner cavity flows to the pressure tube 10 .

[0050] Like this, as long as the volume of the inner cavity becomes smaller, the sizing material in the inner cavity will be squeezed to the pressure material tube 10 . As long as the volume of the inner cavity becomes larger, the glue material of the suction pipe 9 is sucked into the inner cavity. Simple and convenient, reducing the complexity of the control system.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com