Thermal fusion welding tool and technology of chip of vehicle ABS sensor

A hot-melt welding and sensor technology, applied in welding equipment, laser welding equipment, welding/welding/cutting items, etc., can solve the problems of welding current chip influence, low welding efficiency, virtual welding, etc., and achieve stable use, Improved welding efficiency and strong pull-out resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The application will be described in further detail below in conjunction with the accompanying drawings. It is necessary to point out that the following specific embodiments are only used to further illustrate the application, and cannot be interpreted as limiting the protection scope of the application. The above application content makes some non-essential improvements and adjustments to this application.

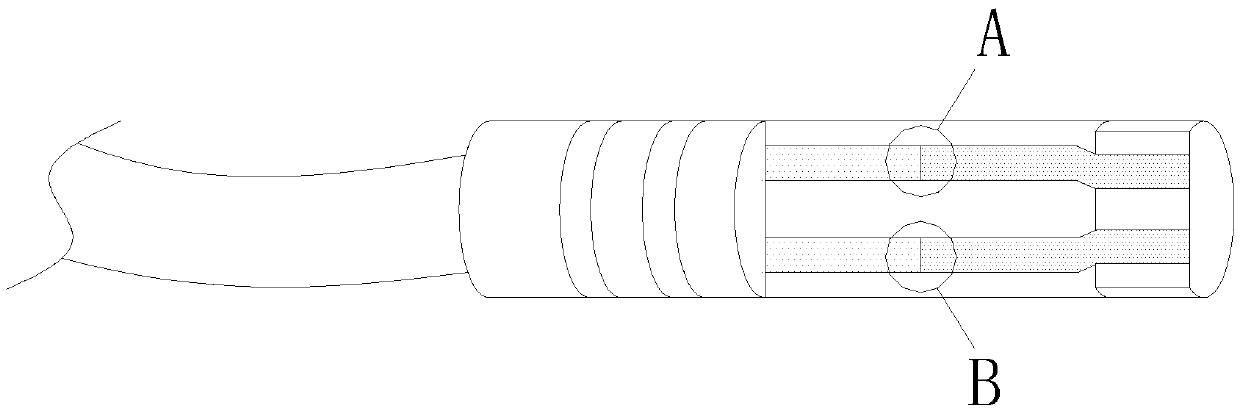

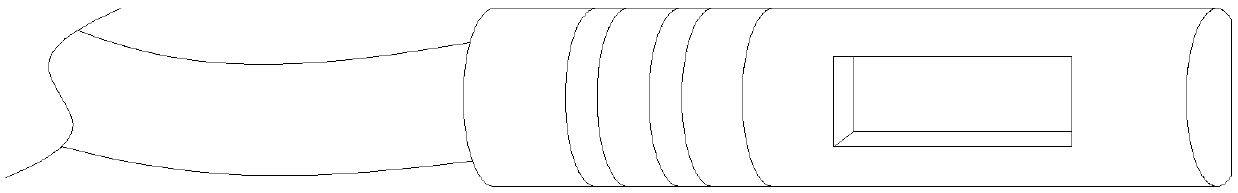

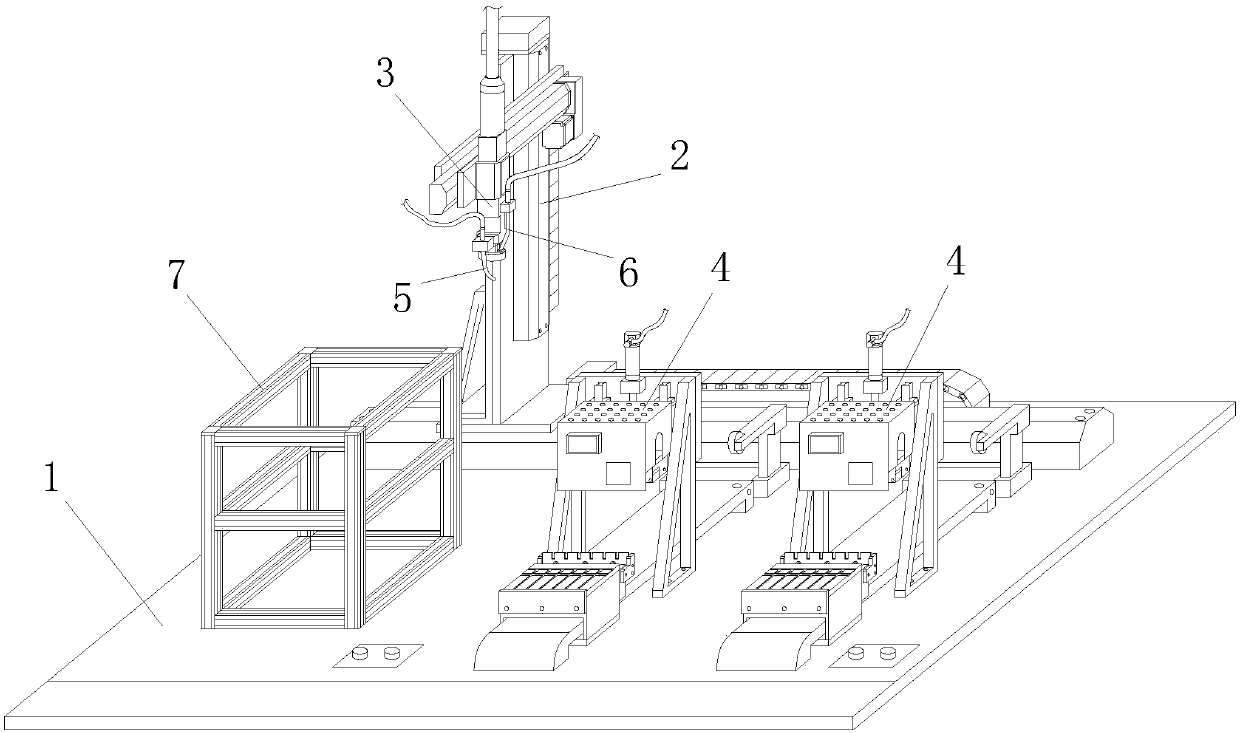

[0024] to combine Figure 3 to Figure 6 As shown, a structure of an embodiment of the present invention is introduced, a chip thermal fusion welding tool for a vehicle ABS sensor, including an operating table 1, which is provided with a module mechanism 2, a laser welding head 3 and two or two More than one welding station 4.

[0025] Among them, the module mechanism 2 is composed of three linear modules, which are driven by electricity. Refer to the attached drawings for the specific installation structure, which will not be introduced in detail here; the laser w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com