Manufacturing and mounting technology of marine food-grade pipeline

An installation process, food-grade technology, applied in the direction of pipeline laying and maintenance, pipe/pipe joint/pipe fitting, sleeve/socket connection, etc. The raw material manufacturing process and connection structure form are not up to the standard, so as to achieve high reliability, reduced maintenance, and avoid easy pollution.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

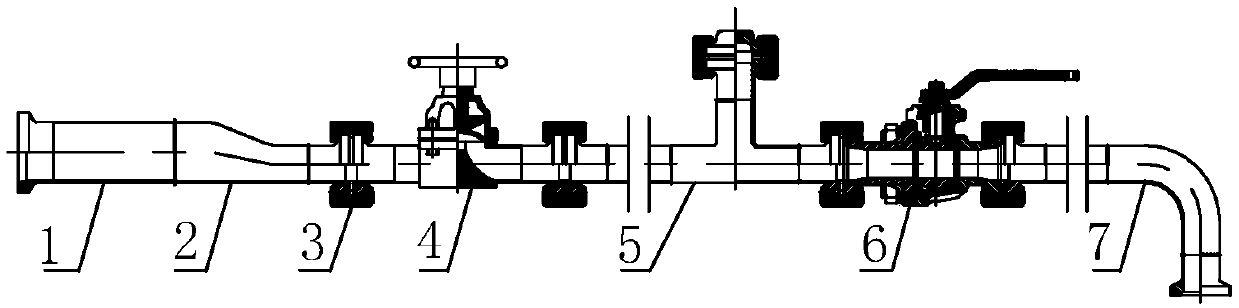

[0014] refer to Figure 1 to Figure 3 The manufacture and installation process of the marine food-grade pipeline of the present invention will be further described.

[0015] A manufacturing and installation process for marine food-grade pipelines, comprising the following steps:

[0016] 1) Parts preparation, the stainless steel pipe 1 is prefabricated in a clean workshop, and all parts that need to be welded with the stainless steel pipe 1 are welded in the workshop. After welding, the weld seam is polished, and the inside of the stainless steel pipe 1 is cleaned. And keep it clean, the parts usually include eccentric reducer 2, diaphragm valve 4, tee 5, ball valve 6 and elbow 7;

[0017] 2) For installation on a ship, transfer all the stainless steel pipes 1 to the ship, and connect them in sequence, and connect two adjacent stainless steel pipes 1 through clamp joints 3 .

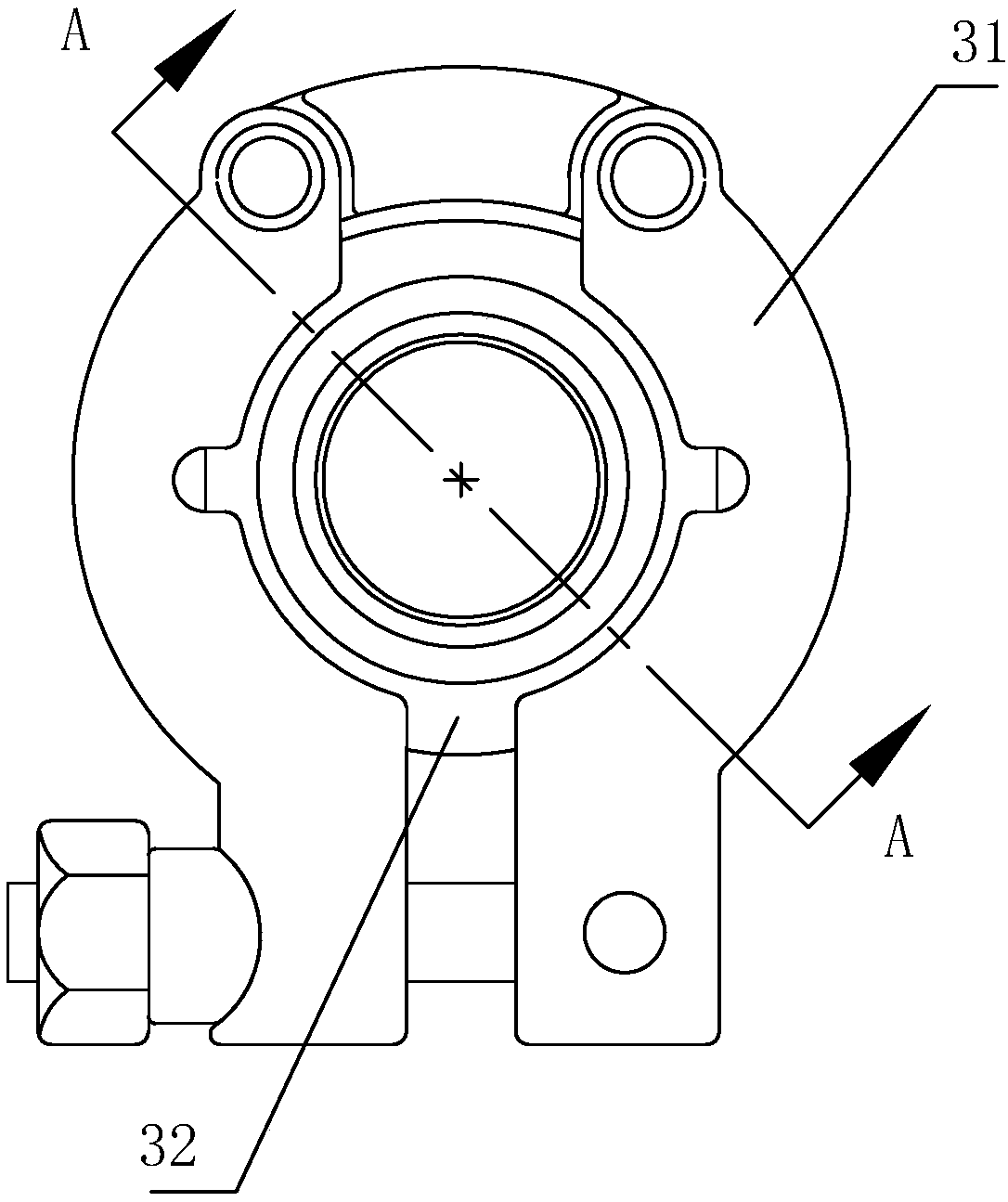

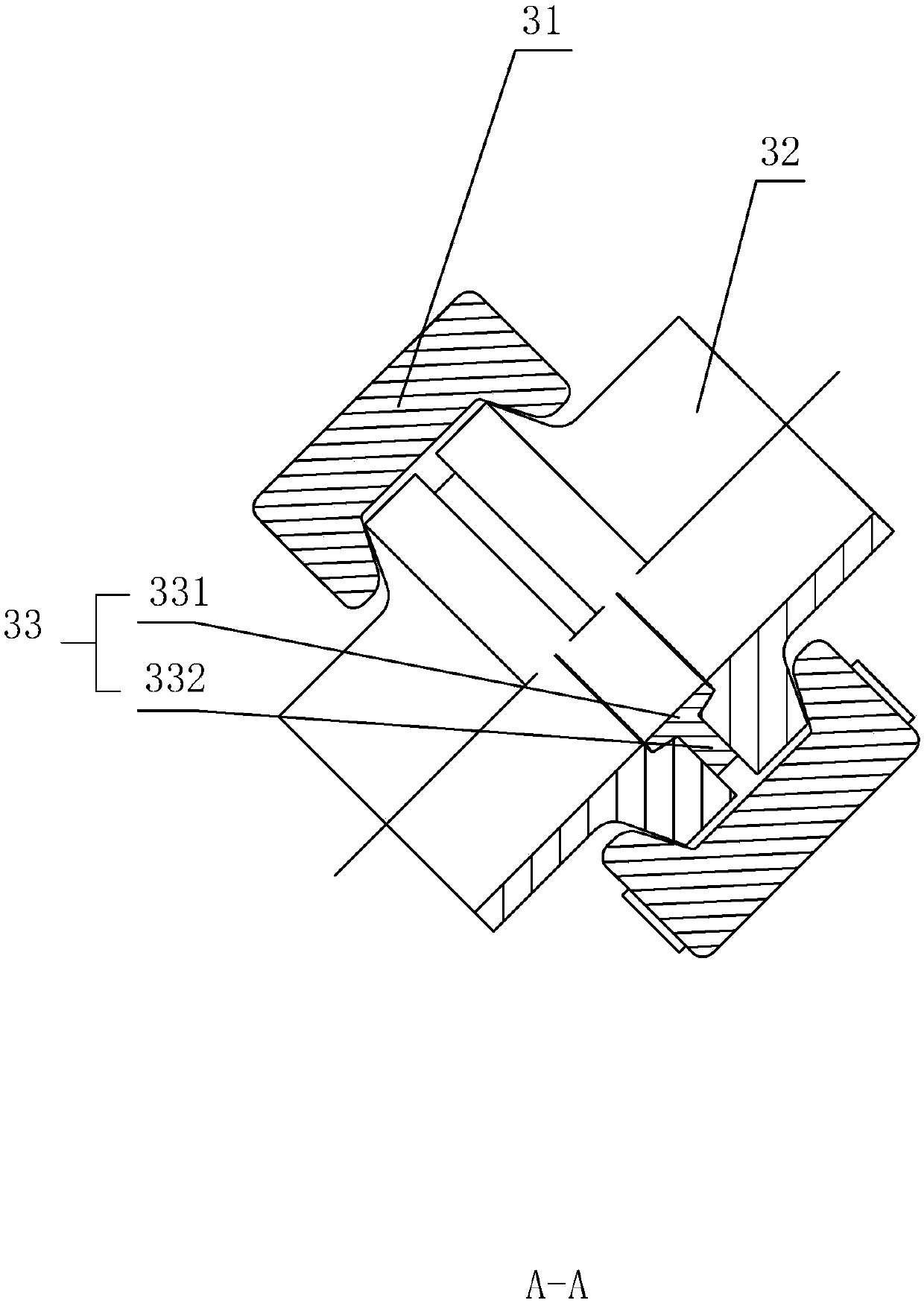

[0018] The clamp joint 3 includes two sections of connecting core 32, gasket 33 and clamp 31, and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com