Circular pipe automatic cutting machine

A round pipe and cutting machine technology, applied in metal processing machinery parts, large fixed members, clamping and other directions, can solve the problems of large parallelism error of the end face of the steel pipe, large waste of materials, low processing accuracy, etc., to increase cutting Accuracy, convenient and practical processing, reasonable structure and layout

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

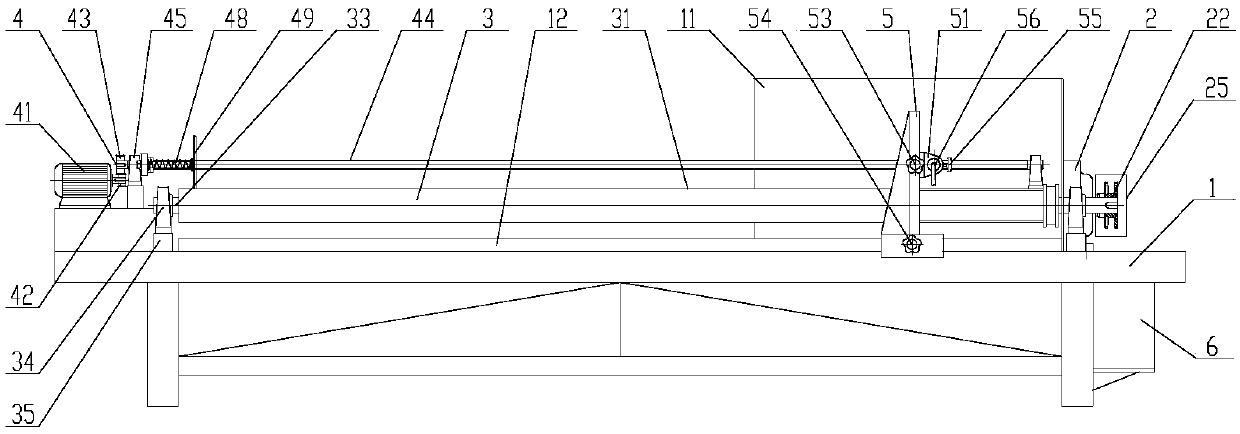

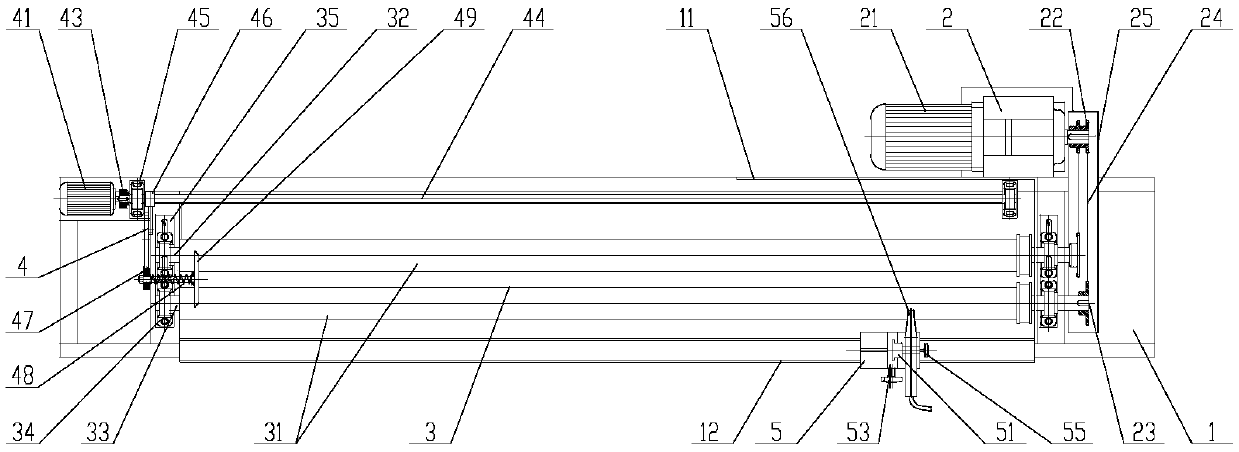

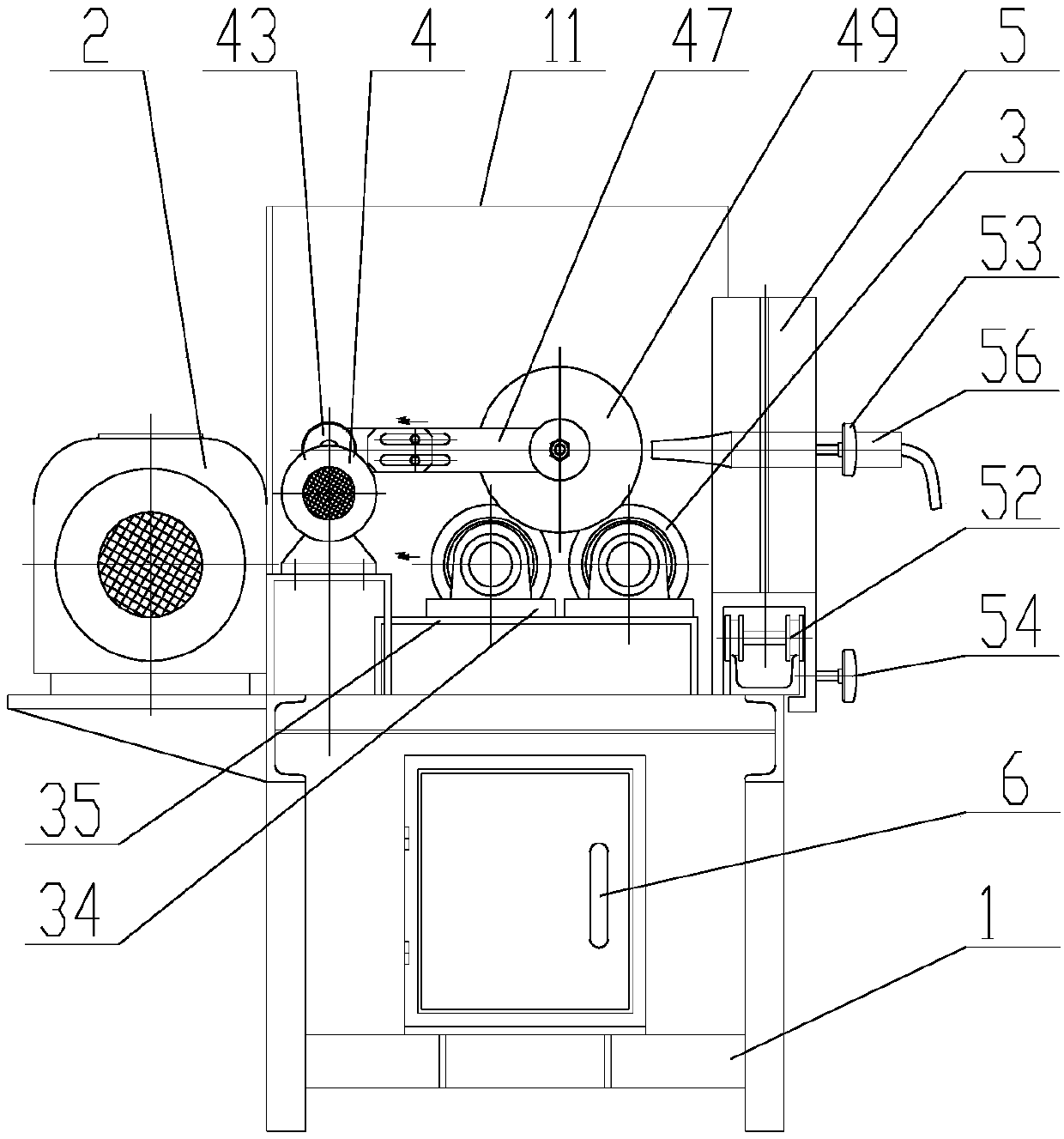

[0019] Such as Figure 1-4 As shown, a circular pipe automatic cutting machine includes a frame 1, a workpiece supporting mechanism 3 arranged on the frame 1, a host drive system 2 arranged at one end of the workpiece supporting mechanism 3, and a The automatic pipe feeding system 4 at the other end of the workpiece support mechanism 3 and the tool rest control device 5 arranged on the workpiece support mechanism 3, the one end of the workpiece support mechanism 3 is also provided with an electric control box 6, and the electric control box 6 It is arranged under the main engine transmission system 2; the main engine transmission system 2 can drive the workpiece support mechanism 3 to rotate; when cutting a circular tubular workpiece, the workpiece is placed on the workpiece support mechanism to support the workpiece Function, it is convenient to make the tool holder control device and the workpiece on the same level, so as to facilitate the cutting of the circular tube workpi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com