Stirrer for concrete stirring station

A mixing station and mixing machine technology, which is applied in mixing plants, cement mixing devices, clay preparation devices, etc., can solve problems such as cement mortar that is easy to condense, and achieve the effect of uniform mixing of concrete

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The following is further described in detail through specific implementation methods:

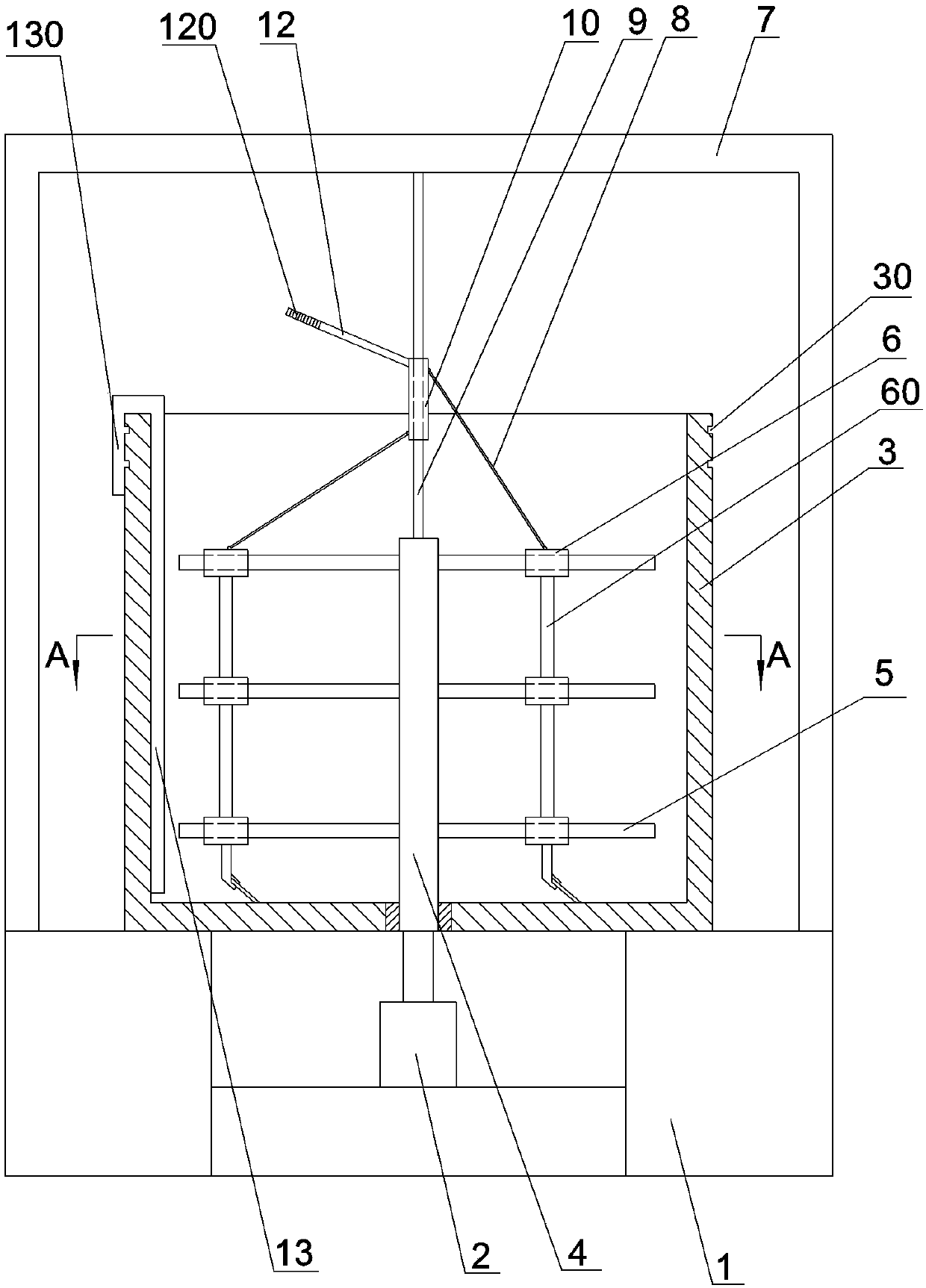

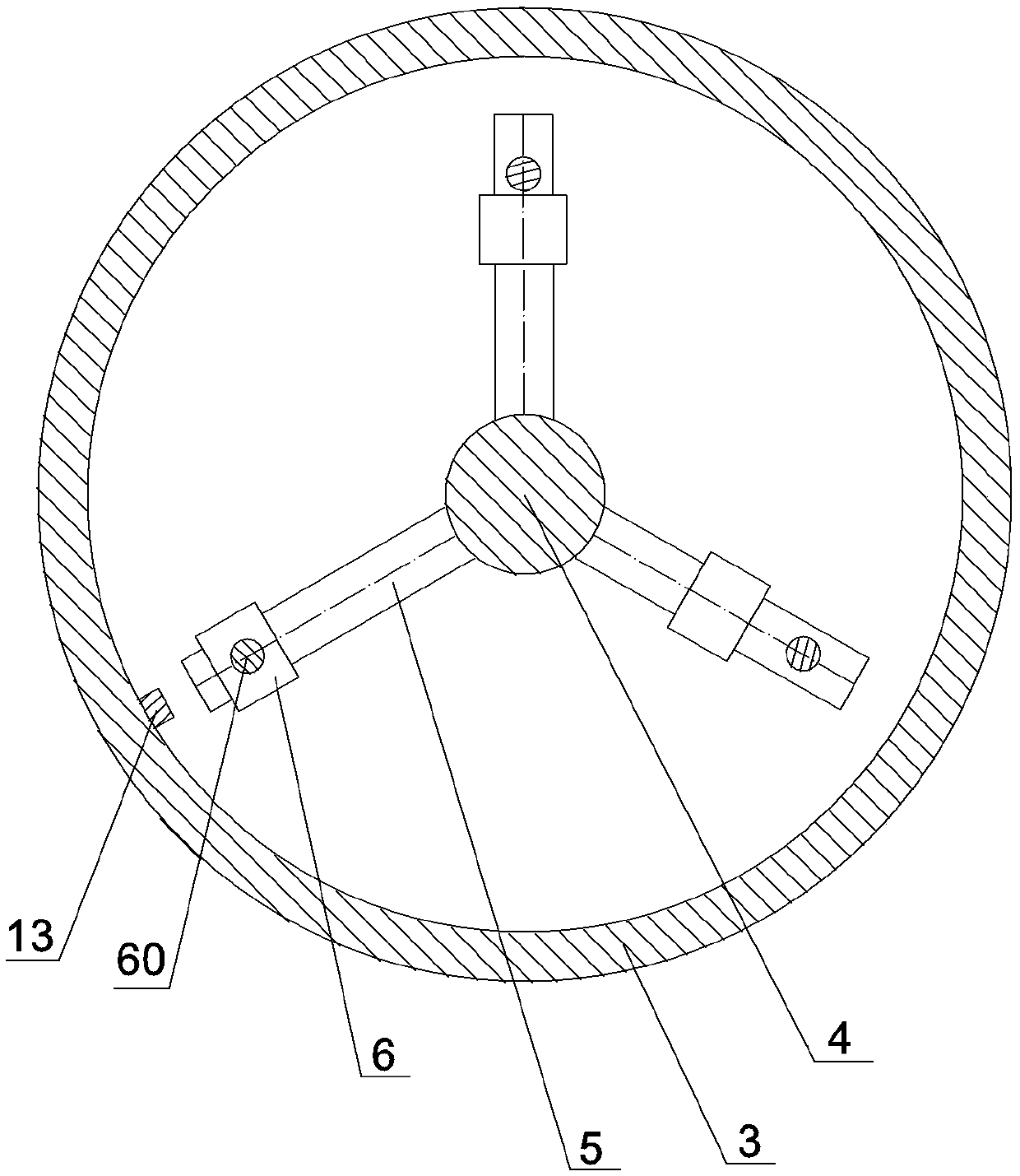

[0022] The reference signs in the drawings of the description include: base 1, motor 2, mixing drum 3, annular groove 30, stirring shaft 4, stirring blade 5, scraping sleeve 6, vertical stirring arm 60, bracket 7, connecting rod 8 , support rod 9, sliding sleeve 10, pressing rod 12, anti-skid pattern 120, scraping rod 13, bending part 130.

[0023] Such as figure 1 with figure 2 As shown, a mixer for a concrete mixing station in this embodiment includes a circular base 1 and a mixing drum 3 installed on the base 1, and a door-shaped bracket 7 is welded on the base 1, and the door-shaped The top of the support 7 is located above the mixing drum 3, the mixing drum 3 is provided with a stirring shaft 4, the top of the stirring shaft 4 is coaxially welded with a support rod 9, the top of the support rod 9 is connected to the top of the support 7 through a bearing, and the base 1 is pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com