Battery pack impact resistance structure device based on shear thickening material

A battery pack and impact-resistant technology, applied in transportation and packaging, vehicle safety arrangements, bumpers, etc., can solve problems such as deformation of deformed battery packs, safety issues, etc., to improve passability, avoid large deformation, and ensure mechanical integrity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be described in detail below in conjunction with the accompanying drawings and examples.

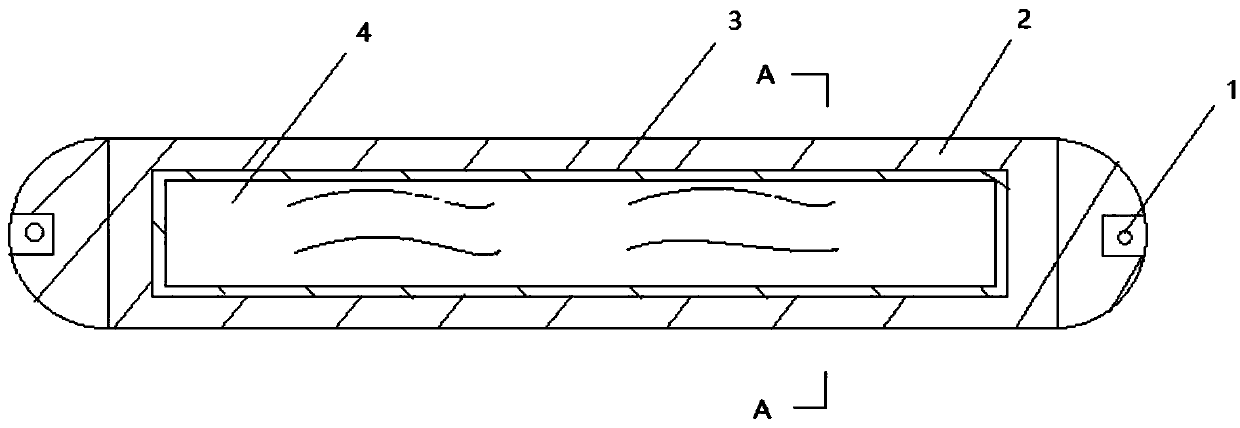

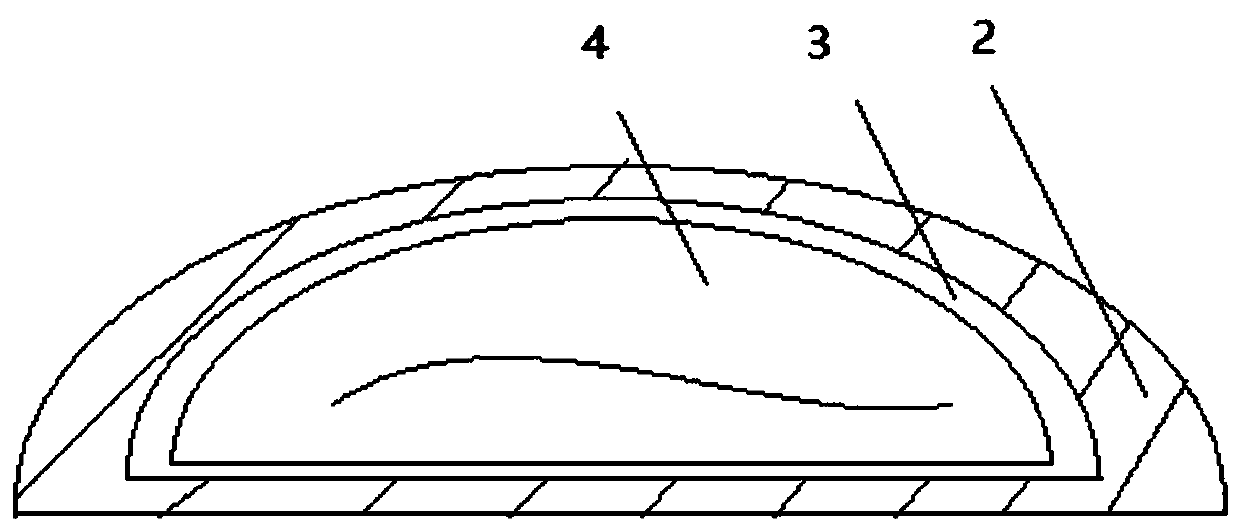

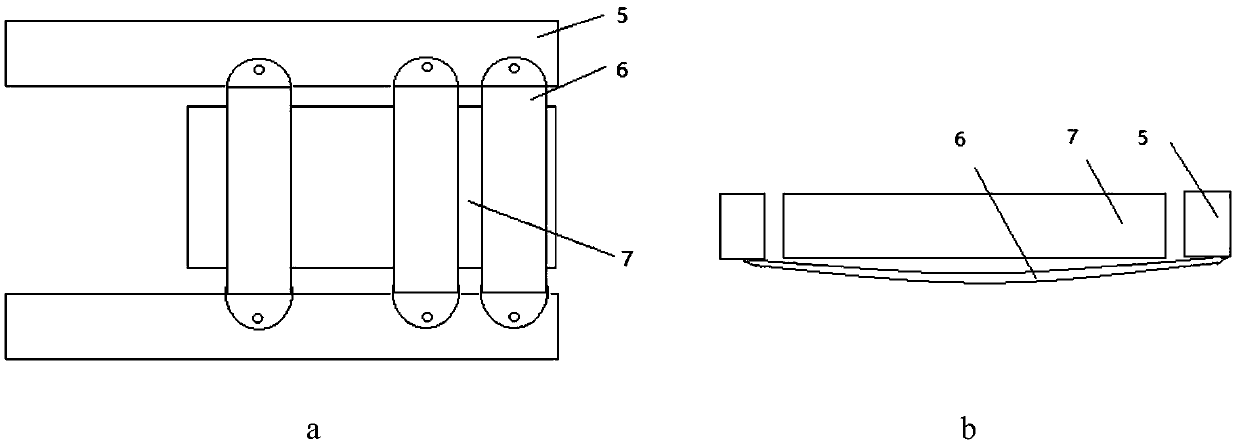

[0020] Such as figure 1 , 2 As shown, the present invention is based on a shear-thickening material battery pack impact-resistant structural device, including a filler 4, the filler 4 is made of DST shear-thickening material, and the outer layer of the filler 4 is provided with a soft rubber capsule 3 , the outer layer of the soft rubber bag 3 is provided with a hard rubber protective cover 2, the cross section of the hard rubber protective cover 2 is arc-shaped, and the two ends are connected with the vehicle frame by bolts 1. in layout as image 3 As shown in a and b, three battery pack impact-resistant structural devices 6 are used, which are connected to the longitudinal beams 5 at both ends of the vehicle frame, and the layout method of "sparse at the front and dense at the back" is adopted. For specific forms, see image 3 In a, the distance be...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com