A method for preparing graphene with high lubricity using ionic liquid

A technology of ionic liquid and lubricating performance, applied in lubricating compositions, petroleum industry, etc., can solve problems such as easy agglomeration, difficult dispersion of graphene, poor lubricating performance, etc., achieve excellent lubricating performance, low equipment requirements, and easy preparation process The effect of green environmental protection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

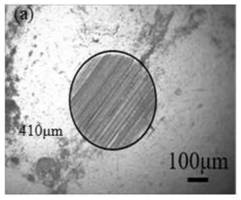

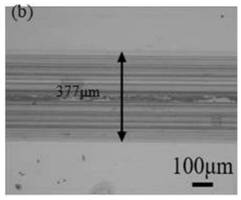

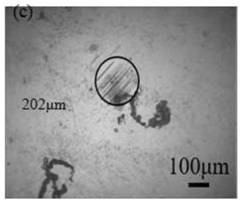

[0033] Weigh 2g of natural flake graphite powder and 1g of sodium nitrate in a three-necked flask, place it in an ice bath, add 46ml of concentrated sulfuric acid under stirring conditions, and slowly add 6g of potassium permanganate after completion, and stir for 3h under an ice bath. After low-temperature reaction, the temperature was raised to 35° C. and stirred for 1 h, and then 92 ml of deionized water was added and the temperature was raised to 90° C. for high-temperature reaction for 3 h. Finally, 150ml of deionized water and 10ml of 30% hydrogen peroxide were added, and the color of the liquid turned yellow, indicating that graphite oxide was successfully prepared. Then use 5% dilute hydrochloric acid and deionized water to wash by centrifugation at 8000r / min for 5min until it is neutral and free of sulfate ions, and then the graphene oxide is made into an aqueous solution and placed in a beaker. Transmission electron microscope pictures of graphene oxide as Figure 1a...

Embodiment 2

[0037] Weigh 2g of natural flake graphite powder and 1g of sodium nitrate in a three-necked flask, place it in an ice bath, add 46ml of concentrated sulfuric acid under stirring conditions, and slowly add 6g of potassium permanganate after completion, and stir for 3h under an ice bath. After the reaction at low temperature, the temperature was raised to 35° C. and stirred for 1 h, and then 92 ml of deionized water was added and the temperature was raised to 90° C. for high temperature reaction for 3 h. Finally, 150ml of deionized water and 10ml of 30% hydrogen peroxide were added, and the color of the liquid turned yellow, indicating that graphite oxide was successfully prepared. Then use 5% dilute hydrochloric acid and deionized water to wash by centrifugation at 8000r / min for 5min until it is neutral and free of sulfate ions, and then the graphene oxide is made into an aqueous solution and placed in a beaker.

[0038] Dilute the graphene oxide aqueous solution prepared above...

Embodiment 3

[0041] Weigh 2g of natural flake graphite powder and 1g of sodium nitrate in a three-necked flask, place it in an ice bath, add 46ml of concentrated sulfuric acid under stirring conditions, and slowly add 6g of potassium permanganate after completion, and stir for 3h under an ice bath. After low-temperature reaction, the temperature was raised to 35° C. and stirred for 1 h, and then 92 ml of deionized water was added and the temperature was raised to 90° C. for high-temperature reaction for 3 h. Finally, 150ml of deionized water and 10ml of 30% hydrogen peroxide were added, and the color of the liquid turned yellow, indicating that graphite oxide was successfully prepared. Then use 5% dilute hydrochloric acid and deionized water to wash by centrifugation at 8000r / min for 5min until it is neutral and free of sulfate ions, and then the graphene oxide is made into an aqueous solution and placed in a beaker.

[0042] Dilute the graphene oxide aqueous solution prepared above to 3mg...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com