High light-fastness acid dye and preparation method and application thereof

An acid dye and fastness technology, applied in the field of dyes, to achieve the effects of wide application range, simple preparation method and high light fastness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

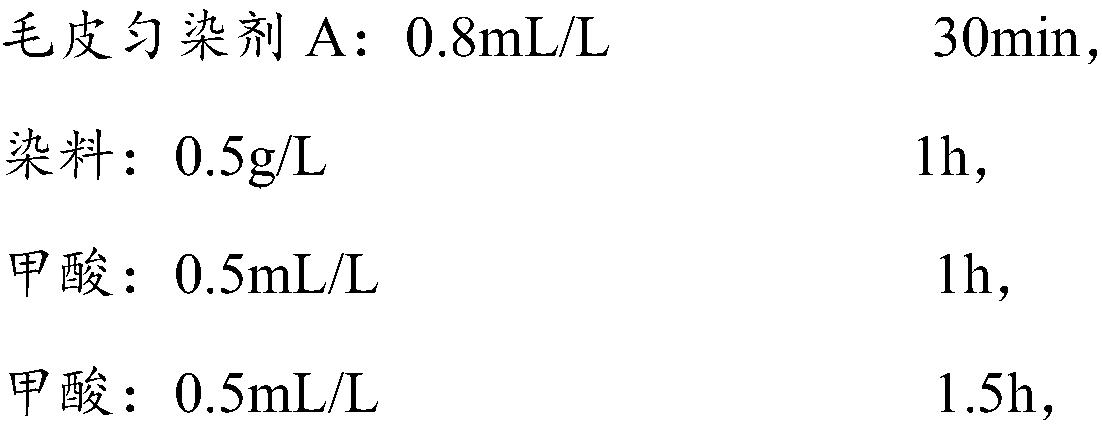

Method used

Image

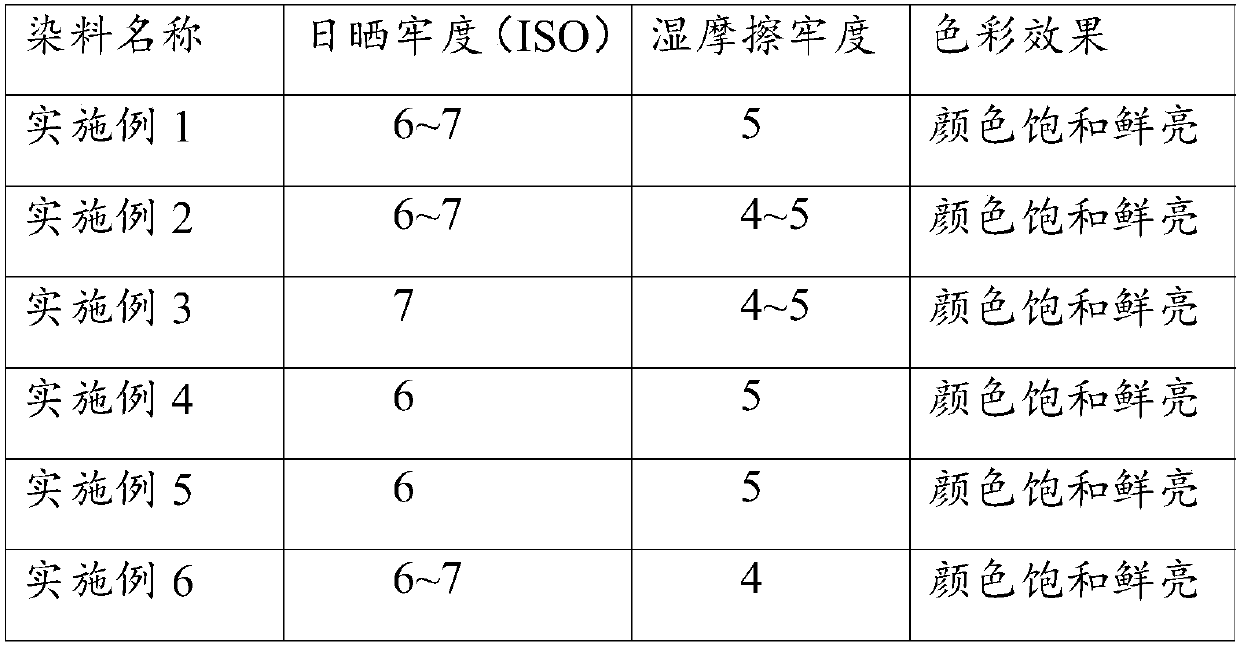

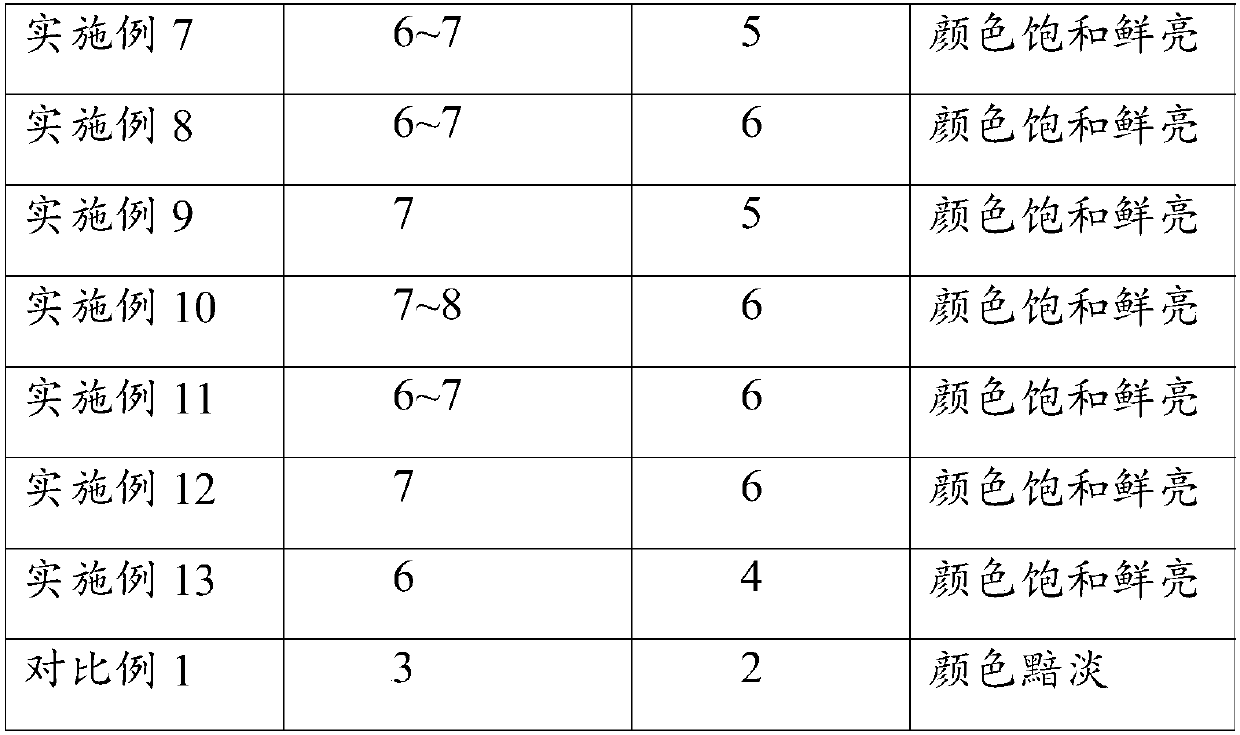

Examples

Embodiment 1

[0044] The dyestuff includes Acid Yellow 29 with a weight of 10 g; an ultraviolet absorber 531 with a weight of 30 g; a light stabilizer 770 with a weight of 20 g; and a pull-off powder with a weight of 21 g.

[0045] Put the acid dye in the mixing kettle and heat it to 12°C;

[0046] Into the reaction kettle, according to the weight of various raw materials, add ultraviolet absorber 531, light stabilizer 770, and pull apart powder, stir for 7 hours, make it mix evenly, and obtain powdery dye.

Embodiment 2

[0048] The dyestuff includes acid red 34 with a weight of 20 g; ultraviolet absorber 531 with a weight of 20 g; light stabilizer 770 with a weight of 10 g; and pull-off powder with a weight of 50 g.

[0049] Put the acid dye in the mixing kettle and heat it to 50°C;

[0050] Into the reaction kettle, according to the weight of various raw materials, add ultraviolet absorber 531, light stabilizer 770, and pull apart powder, stir for 6 hours, make it mix uniformly, and obtain powdery dye.

Embodiment 3

[0052] The dyestuff includes Acid Yellow 17 with a weight of 15g; an ultraviolet absorber 531 with a weight of 30g; a light stabilizer 770 with a weight of 20g; and a pull-off powder with a weight of 35g.

[0053] Put the acid dye in the mixing kettle and heat it to 26°C;

[0054] Into the reaction kettle, according to the weight of various raw materials, add ultraviolet absorber 531, light stabilizer 770, and pull apart powder, stir for 5 hours, make it mix evenly, and obtain powdery dye.

PUM

| Property | Measurement | Unit |

|---|---|---|

| color fastness | aaaaa | aaaaa |

| color fastness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com