Test method of lithium ion battery slurry viscoelasticity

A lithium-ion battery and testing method technology, which is applied in the field of viscoelasticity testing of lithium-ion battery slurry, can solve problems such as instability of viscoelasticity test data, influence of coating characteristics, etc., and achieve simple operation and good repeatability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

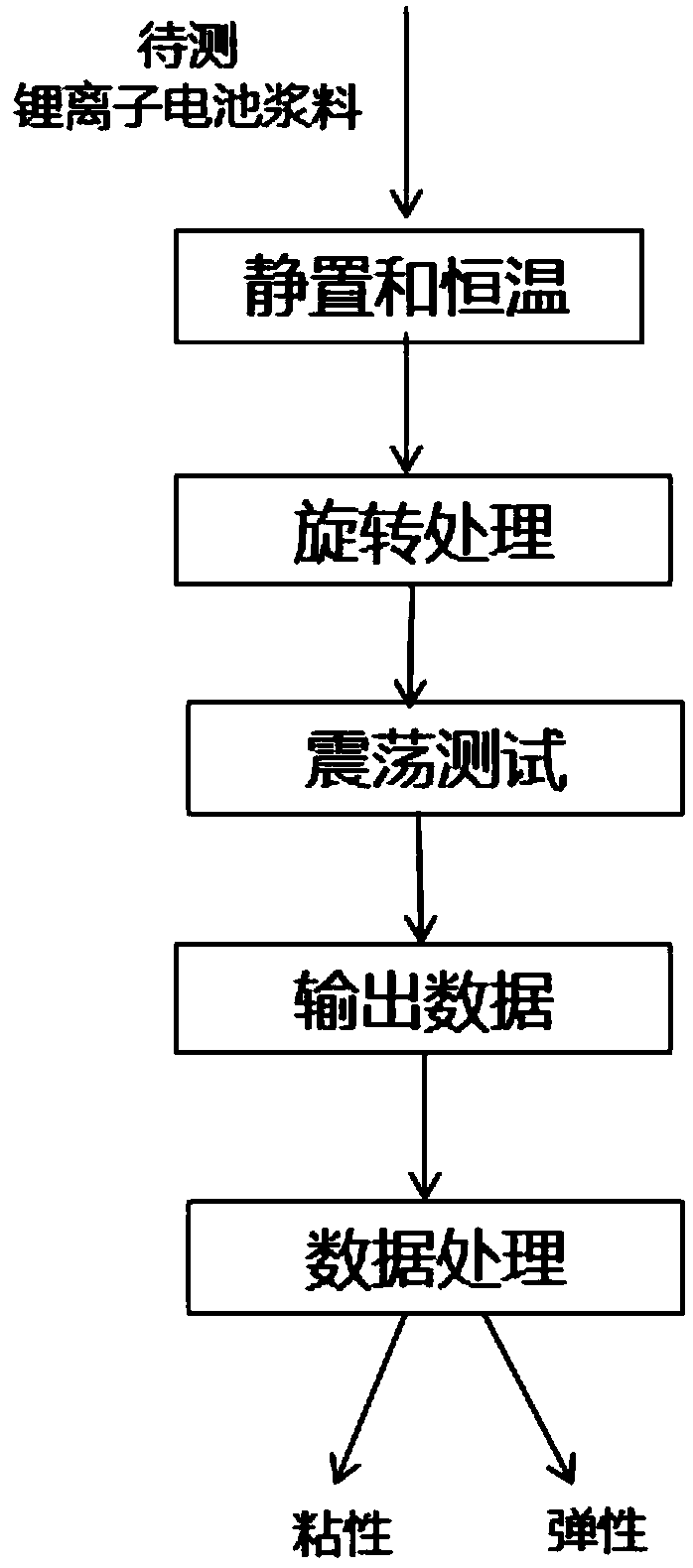

[0044] According to this embodiment figure 1 The process shown is carried out. Specifically, take the slurry A of the positive electrode material of the lithium ion battery (NCM:SP:PVDF is mixed in a mass ratio of 96:2:2, the same below), stir for 10 minutes and mix, and then add the sample to the In the rheometer, stand still for 10 minutes. At this time, the temperature of the slurry is constant at 25°C±0.5°C. Start the rotation module of the rheometer for rotation processing. The rotation processing process includes: 100s at the first shear rate -1 Rotate the rotor for 5min, then at the second shear rate 00.01s -1 Rotate the rotor for 15 minutes, close the rotary module of the dynamic rheometer, and obtain the processed sample; start the vibration module of the rheometer, and perform a vibration test. The vibration test process includes: setting the range of the shear strain to 0.1%- 101%, and take 19 points by the method of logarithmically divided points, record the shear...

Embodiment 2

[0049] Carry out according to the method of embodiment 1, difference is: add sample to rheometer through spatula.

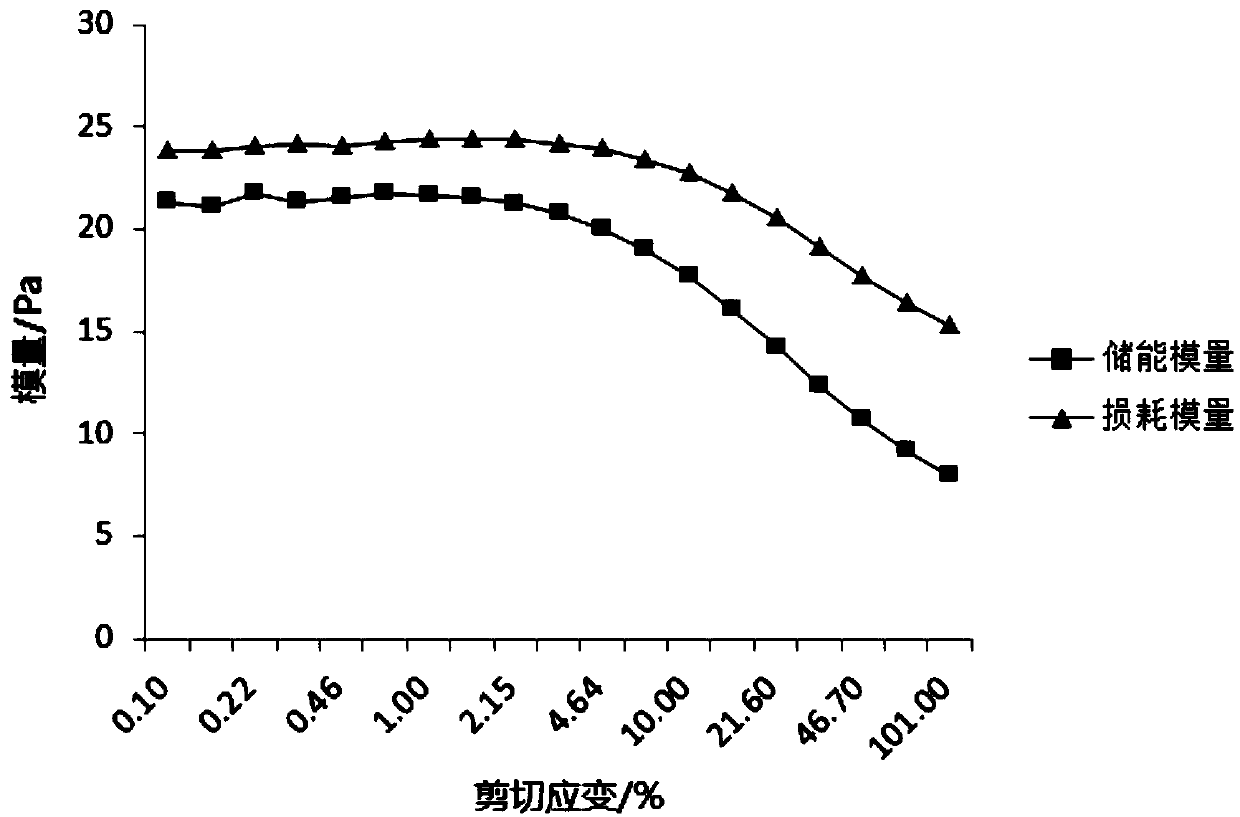

[0050] The results of this embodiment are shown in Table 2 and image 3 shown by Table 2 and image 3 It can be seen that in this example, the maximum value of the storage modulus representing the elasticity of the slurry is 21.597Pa, the maximum value of the loss modulus representing the viscosity of the slurry is 24.252Pa, and the torque parameter (greater than 1 μN m) reflects The accuracy of the data illustrates the accuracy of the viscoelasticity data in this example.

[0051] Table 2

[0052] data point number

Embodiment 3

[0054] Repeat the operation according to the method of Example 1.

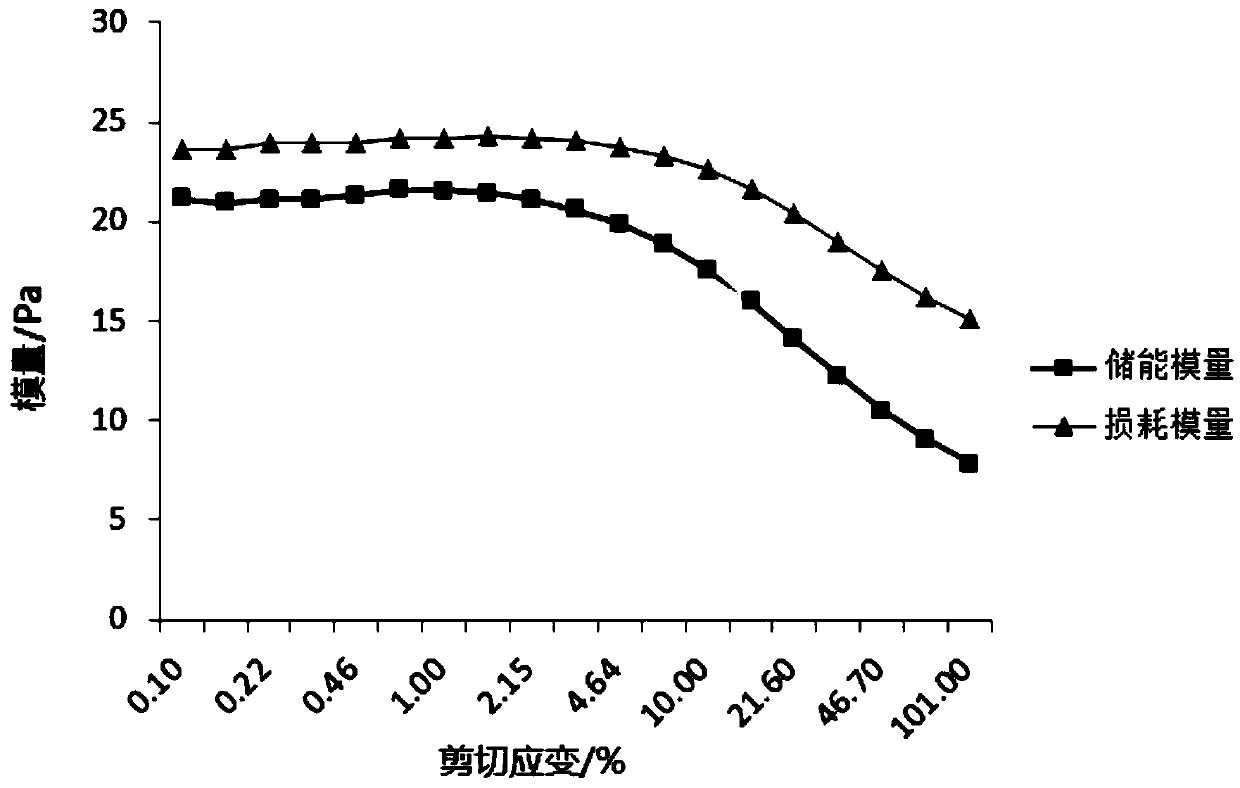

[0055] The results of this embodiment are shown in Table 3 and Figure 4 shown by Table 3 and Figure 4 It can be seen that in this embodiment, the maximum value of the storage modulus representing the elasticity of the slurry is 21.683Pa, the maximum value of the loss modulus representing the viscosity of the slurry is 24.272Pa, and the torque parameter (greater than 1 μN m) reflects The accuracy of the data illustrates the accuracy of the viscoelasticity data in this example.

[0056] table 3

[0057]

[0058]

PUM

| Property | Measurement | Unit |

|---|---|---|

| Storage modulus | aaaaa | aaaaa |

| Loss modulus | aaaaa | aaaaa |

| Storage modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com